Treatment method for top plate sandstone water of Jurassic coal field

A roof and sandstone technology, which is applied in the field of roof sandstone water treatment in Jurassic coalfields, can solve the problems that it is difficult to achieve ideal, there is no ideal treatment method for roof sandstone water, and the pore size is small, so as to reduce external discharge, protect groundwater resources, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

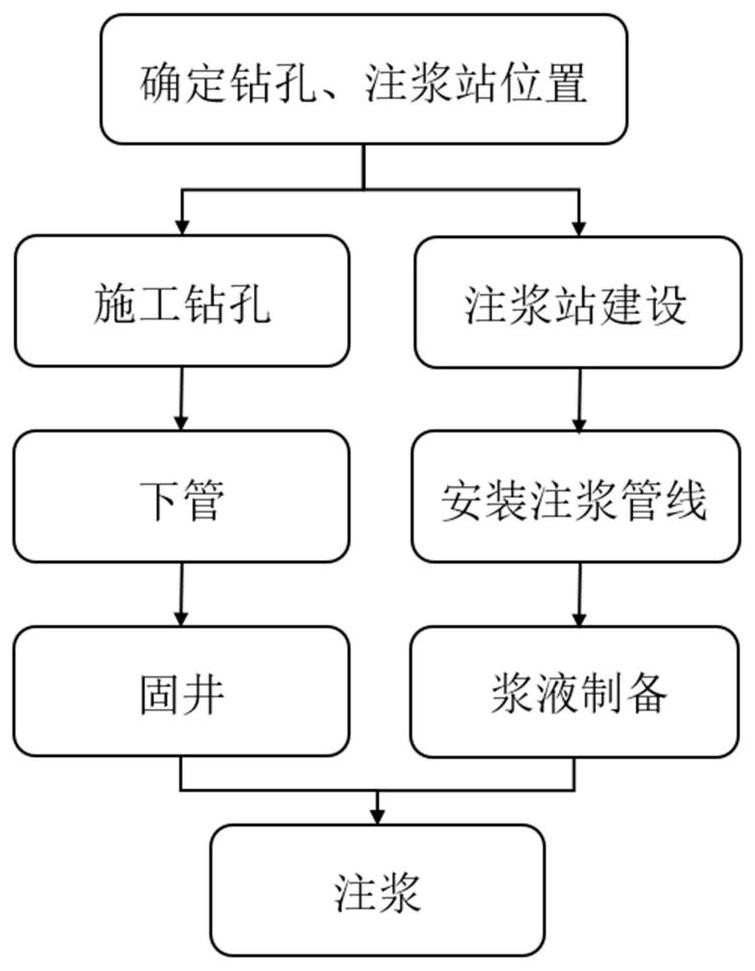

[0038] This embodiment relates to a method for controlling sandstone water on the roof of a Jurassic coalfield, comprising the following steps (the flow chart is as follows: image 3 ):

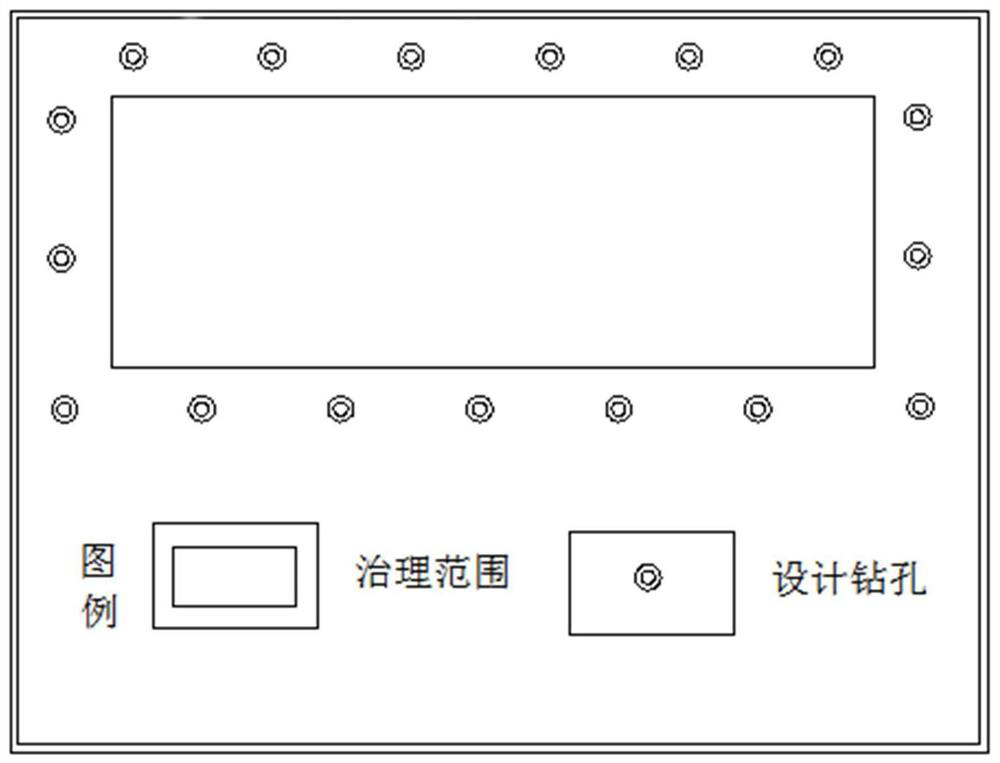

[0039] The first step is to take the mining area as the control area and arrange ground drilling around the mining area. The boreholes are located 50m outside the boundary of the affected area of coal seam mining. The boreholes are arranged in a single ring with a distance of 30m (the schematic diagram is shown in figure 1 ).

[0040] The second step is drilling. The drilling is a three-hole structure, the first hole diameter is 219mm, entering the bedrock 10m, the second hole diameter is 168mm, and the 127mm casing is lowered, the depth is 480m, and the horizon is 10m above the grouting section. The diameter of the third hole is 110mm, which is an open hole, and the depth of the final hole is 600m. The layer of the final hole is the sandstone aquifer of the Luohe Formation, which is the...

Embodiment 2

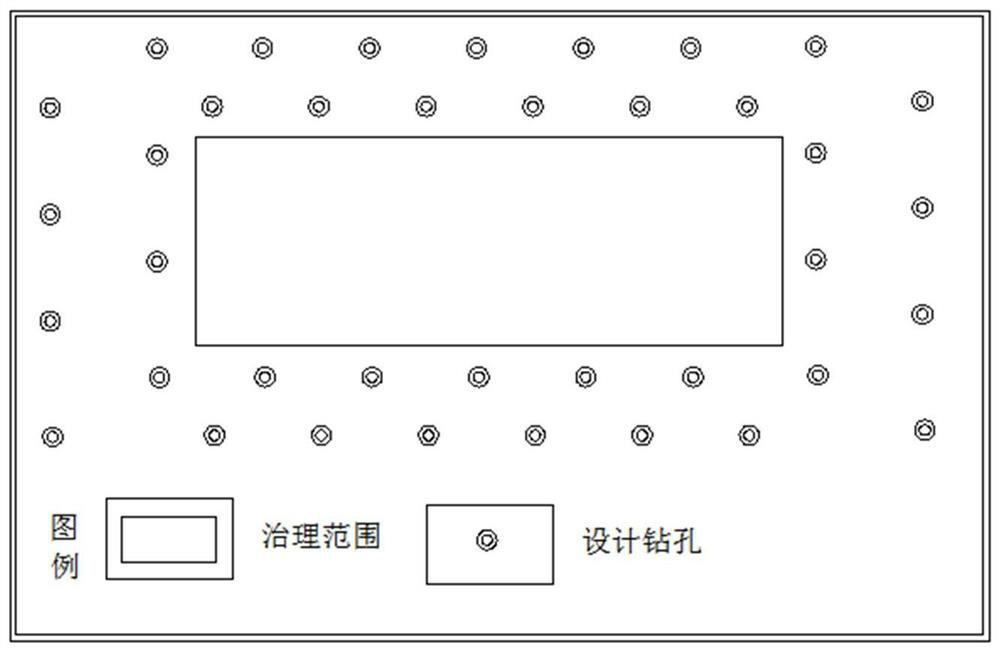

[0047] This embodiment relates to a treatment method for roof sandstone water in a Jurassic coalfield. Compared with Example 1, the difference lies in that in the first step, the mining area is taken as the control range, and ground boreholes are arranged around the mining area. The boreholes are located 50m outside the control boundary, and the boreholes are arranged in a multi-ring manner around the mining area, and the adjacent ring-shaped distribution grouting holes are designed in a staggered manner (the schematic diagram is shown in figure 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com