Anti-fog glasses cloth based on core-shell structure sustained-release microcapsules and preparation method of anti-fog glasses cloth

A slow-release microcapsule and core-shell structure technology, which is applied in glasses/protective glasses, glasses/goggles, chemical instruments and methods, etc. It can solve the problem of water stains on the surface of the lens, affecting the permeability of the lens, and the appearance of a single color, etc. Problems, to achieve the effect of improving the scope of application, good anti-fog effect, and high storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

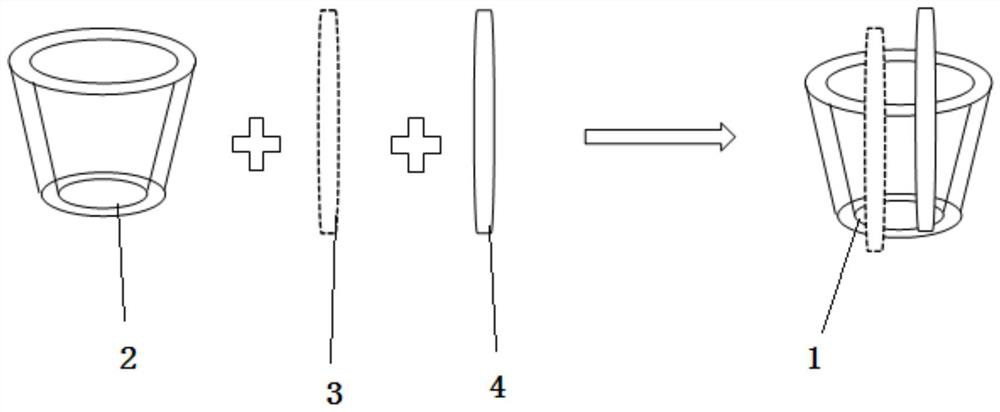

Method used

Image

Examples

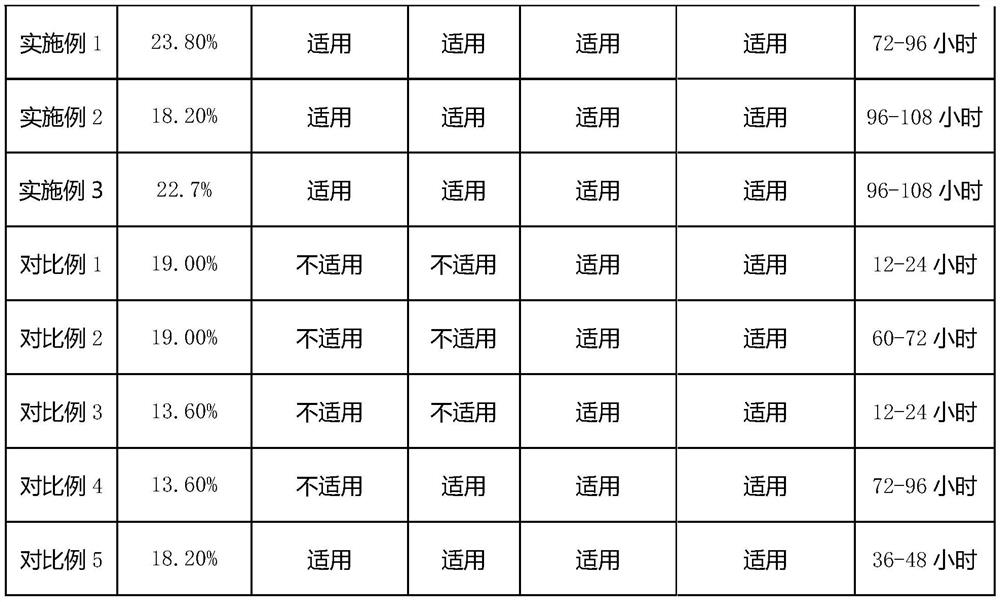

Embodiment 1

[0030] Weigh 130kg of deionized water, add 20kg of absolute ethanol, stir evenly, add 5kg of β-cyclodextrin compound, ultrasonically disperse for 10 minutes, heat to 60°C, and stir at 600r / min for 30 minutes to obtain Add 25kg of polyether-modified silicone BYK-333 and 15kg of sodium laurate to the first dispersion, heat to 80°C, and stir at a speed of 600r / min for 30 minutes to obtain a second milky white dispersion.

[0031] Specification 210g / m 2 The light-yellow base material cloth is sprayed with the pre-configured second dispersion liquid on the upper and lower sides of the cloth through the spraying equipment, and dried through the drying tunnel. After winding, the finished cloth of anti-fog glasses cloth is obtained in rolls. Gram weight is 260g / m 2 ,The above finished cloth is cut into 15cm×15cm size by cutting equipment, anti-fog glasses cloth with jagged edges at right angles.

Embodiment 2

[0033] Weigh 130kg of deionized water, add 20kg of absolute ethanol, stir evenly, add 5kg of hydroxypropyl β-cyclodextrin, ultrasonically disperse for 10 minutes, heat to 60°C, and stir at a speed of 600r / min for 30 minutes, To obtain the first dispersion, add 25kg of polyether-modified organic fluorine DuPont-3100 and 15kg of sodium dodecylbenzenesulfonate, heat to 80°C, and stir at 600r / min for 30 minutes to obtain the milky white second dispersion liquid.

[0034] Specification 220g / m 2 The white substrate cloth is sprayed with the pre-configured second dispersion liquid on the upper and lower sides of the cloth through the spraying equipment, dried in the drying tunnel, and rolled to obtain the finished anti-fog glasses cloth cloth in rolls. The gram of the finished cloth is Weight is 260g / m 2 , The above finished cloth is cut into 13cm×17cm anti-fog glasses cloth with jagged edges and right angles through cutting equipment.

Embodiment 3

[0036] Weigh 130kg of deionized water, add 20kg of absolute ethanol, stir evenly, add 5kg of hydroxypropyl β-cyclodextrin, ultrasonically disperse for 10 minutes, heat to 60°C, and stir at a speed of 600r / min for 30 minutes, To obtain the first dispersion, add 25kg of polyether-modified organic fluorine DuPont-3100 and 15kg of sodium dodecylbenzenesulfonate, heat to 80°C, and stir at 600r / min for 30 minutes to obtain the milky white second dispersion liquid.

[0037] Specification 220g / m 2 The white substrate cloth is cut into a 13cm×17cm size by a cutting device, with jagged edges and right-angled ordinary glasses cloth. Take 130kg of cut glasses and arrange them in the dipping tank, pour the pre-configured second dispersion liquid into the dipping tank, soak for 30 to 60 minutes, and dry to obtain the finished anti-fog glasses cloth, weigh and calculate the finished product The weight of the cloth is 270g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com