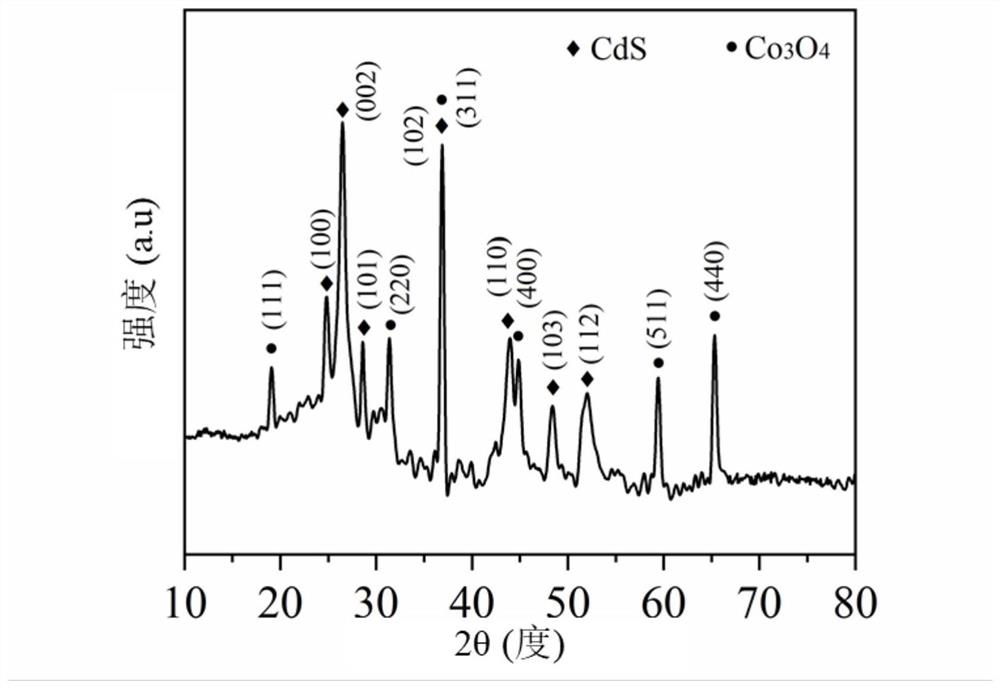

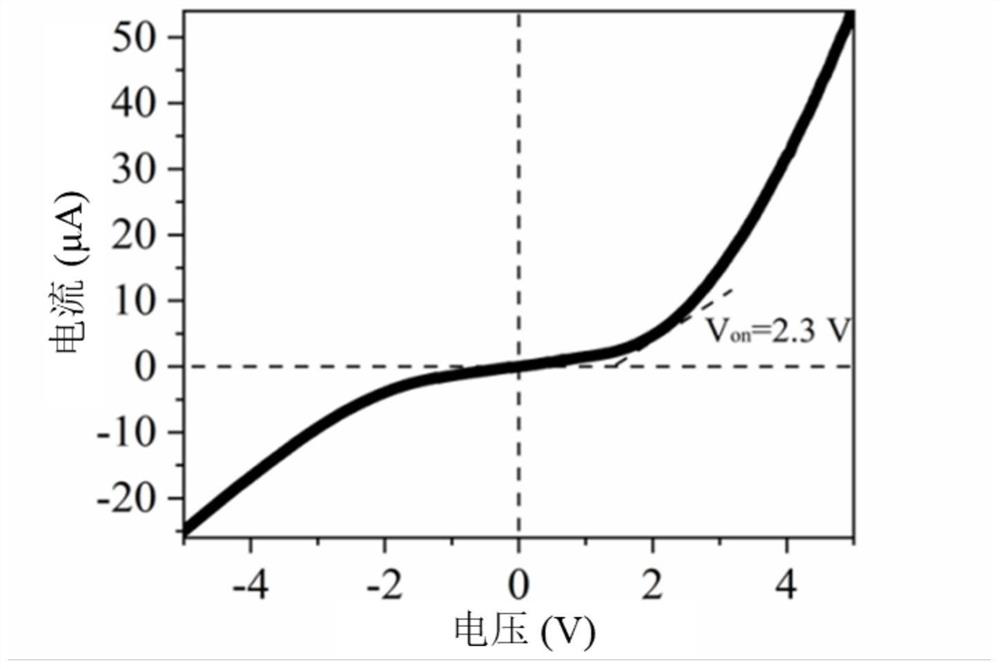

CdS/Co3O4 composite material, preparation method and application of CdS/Co3O4 composite material in acetone gas detection under optical excitation

A composite material, optical excitation technology, applied in the analysis of materials, material resistance, material analysis by electromagnetic means, etc., can solve the problems of high maintenance and use, low detection sensitivity, high price, etc., and achieve fast response and high sensitivity. , the effect of a wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

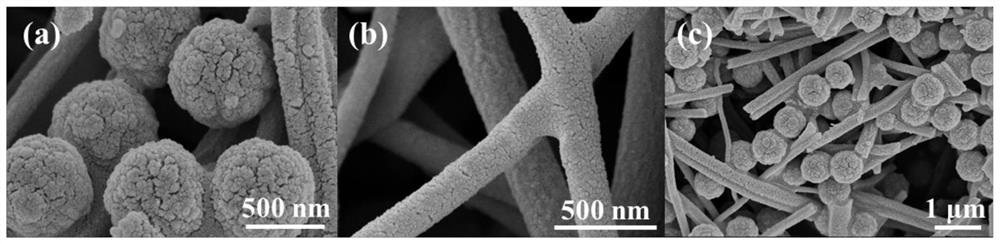

[0110] Example 1 CdS / Co 3 o 4 Preparation of composite materials

[0111] Step 1, weigh 0.9g of polyvinylpyrrolidone (PVP) and dissolve it in the first mixed solvent of 5mL of absolute ethanol and 5mL of N,N-dimethylformamide, stir magnetically for 5h to ensure that it is fully dissolved, and then add 2g Co(NO 3 ) 2 ·6H 2 O and stirring continuously until it is completely dissolved to obtain an electrospinning precursor, which is in a liquid state;

[0112] Step 2, transfer the electrospinning precursor prepared in step 1 to a syringe equipped with a No. 22 (inner diameter 0.4mm) stainless steel needle, and install the syringe containing the electrospinning precursor in the injection system of the electrospinning equipment On the fixture, set the feed rate of the electrospinning precursor to 0.707mL / h, the receiver speed to 80r / min, the distance between the syringe and the receiver to be 15cm, and between the stainless steel needle and the receiver Apply a voltage of ...

Embodiment 2

[0128] Example 2 CdS / Co 3 o 4 Preparation of composite materials

[0129] Step 1, weigh 0.8g polyvinyl alcohol (PVA) and dissolve it in the first mixed solvent of 5mL absolute ethanol and 5mL N,N-dimethylformamide, stir magnetically at 90°C for 5h to fully dissolve the PVA, Then add 1.6g Co(NO 3 ) 2 ·6H 2 O and stirring continuously until it is completely dissolved to obtain an electrospinning precursor, which is in a liquid state;

[0130] Step 2, transfer the electrospinning precursor prepared in step 1 to a syringe equipped with a No. 22 (inner diameter 0.4mm) stainless steel needle, and install the syringe containing the electrospinning precursor in the injection system of the electrospinning equipment On the fixture, set the feed rate of the electrospinning precursor to 0.707mL / h, the receiver speed to 60r / min, the distance between the syringe and the receiver to be 15cm, and between the stainless steel needle and the receiver Apply a voltage of 15kv;

[0131] D...

Embodiment 3

[0134] Example 3 CdS / Co 3 o 4 Preparation of composite materials

[0135] Step 1, weigh 0.8g of polyvinylpyrrolidone (PVP) and dissolve it in 5.5mL of absolute ethanol and 5.5mL of N,N-dimethylformamide mixed first solvent, stir magnetically for 5h to fully dissolve PVP, then add 2g Co(NO 3 ) 2 ·6H 2 O and stirring continuously until it is completely dissolved to obtain an electrospinning precursor, which is in a liquid state;

[0136] Step 2, transfer the electrospinning precursor prepared in step 1 to a syringe equipped with a No. 22 (inner diameter 0.4mm) stainless steel needle, and install the syringe containing the electrospinning precursor in the injection system of the electrospinning equipment On the fixture, set the feed rate of the electrospinning precursor to 0.707mL / h, the receiver speed to 60r / min, the distance between the syringe and the receiver to be 15cm, and between the stainless steel needle and the receiver Apply a voltage of 15kv;

[0137] During...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com