Manufacturing method of vacuum cup with composite inner container

A manufacturing method and technology of thermos cups, which are applied in the field of thermos cups, can solve the problems of heavy overall quality, difficulty in forming, and wall thickness of the inner tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

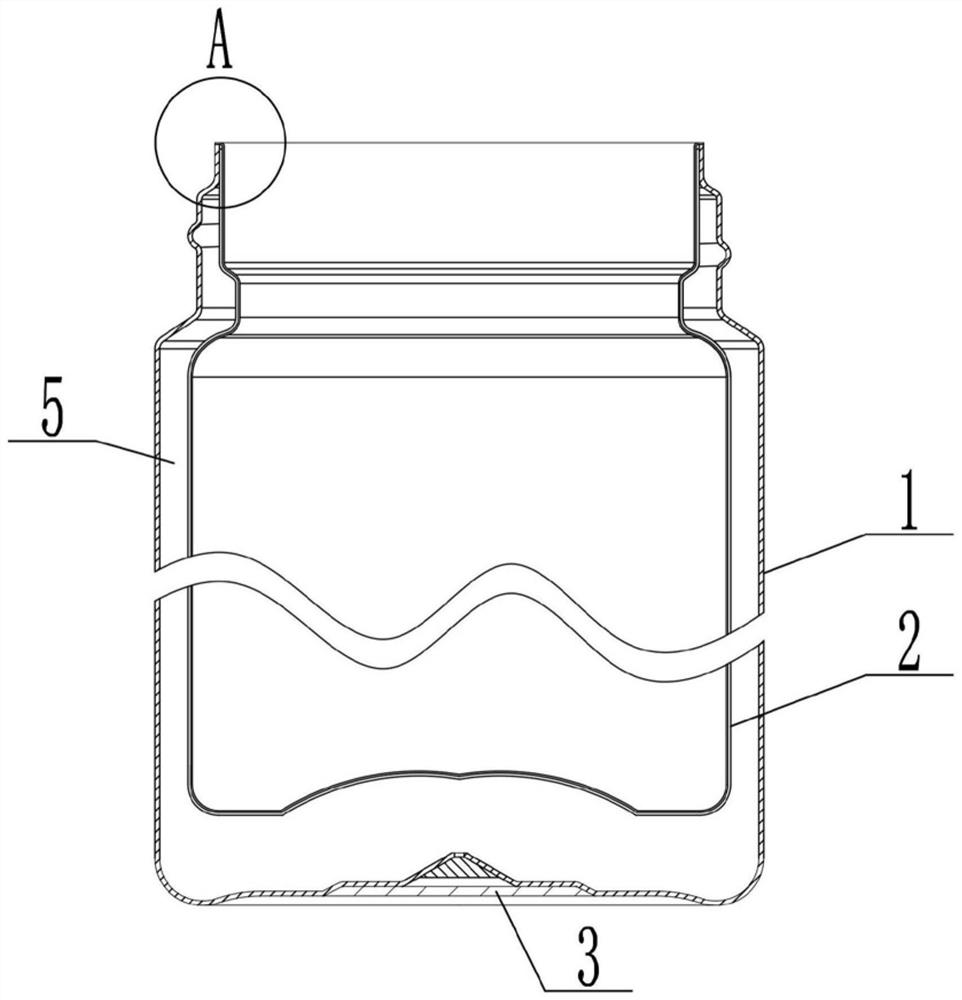

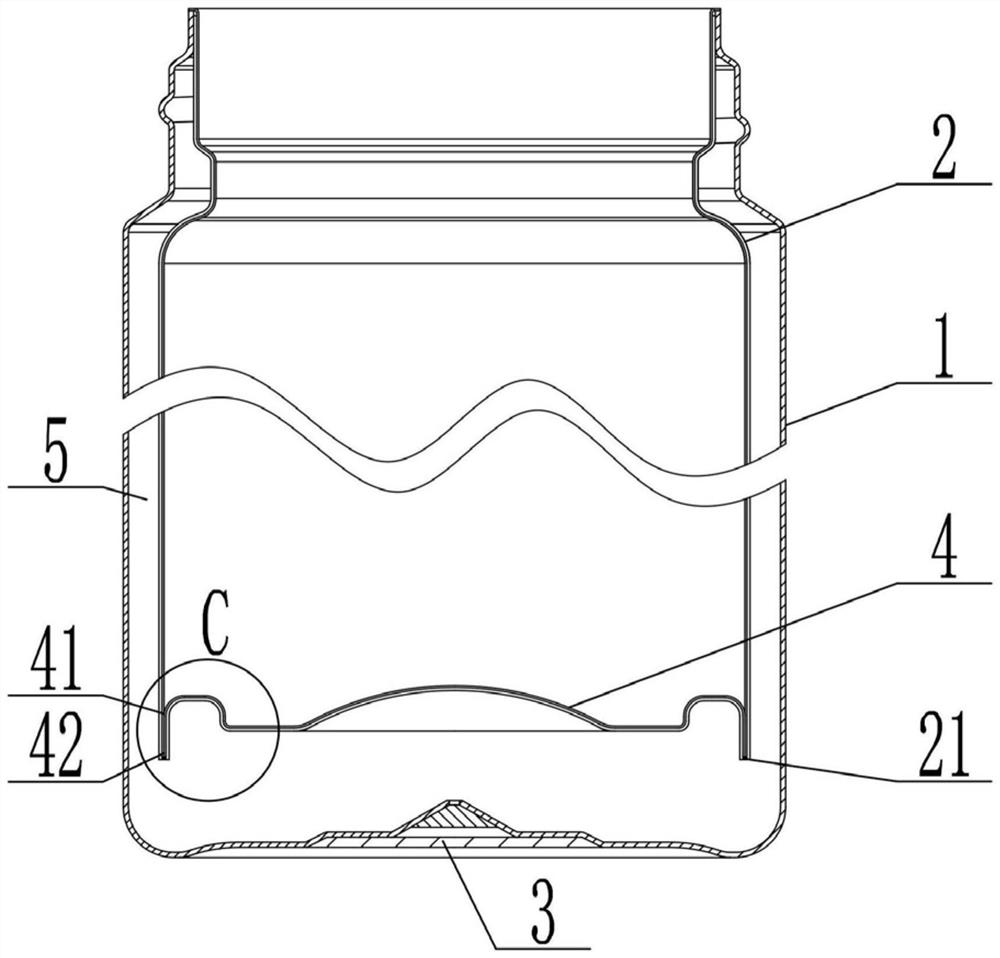

[0056] A method for manufacturing a thermos cup with a composite liner, comprising a stainless steel shell 1, a cup bottom 3, the cup bottom 3 being welded to the bottom of the stainless steel shell 1, and a composite liner 2, the composite liner 2 It is made of a two-layer composite plate with a titanium inner layer 22 and a steel outer layer 23. The mouth of the stainless steel shell 1 is welded to the mouth of the composite inner tank 2, and the stainless steel shell 1 and the composite inner tank are welded together. A vacuum layer 5 is formed between the bladders 2, and its preparation process includes the following steps:

[0057] Q1: Take a two-layer composite plate with a titanium inner layer 22 and a steel outer layer 23, and cut it into discs;

[0058] Q2: Clean the above-mentioned wafers, dry them and place them in a vacuum furnace for annealing, raise the temperature of the vacuum furnace to 600°C within 15 minutes, keep the temperature for 30 minutes, and then use...

Embodiment 2

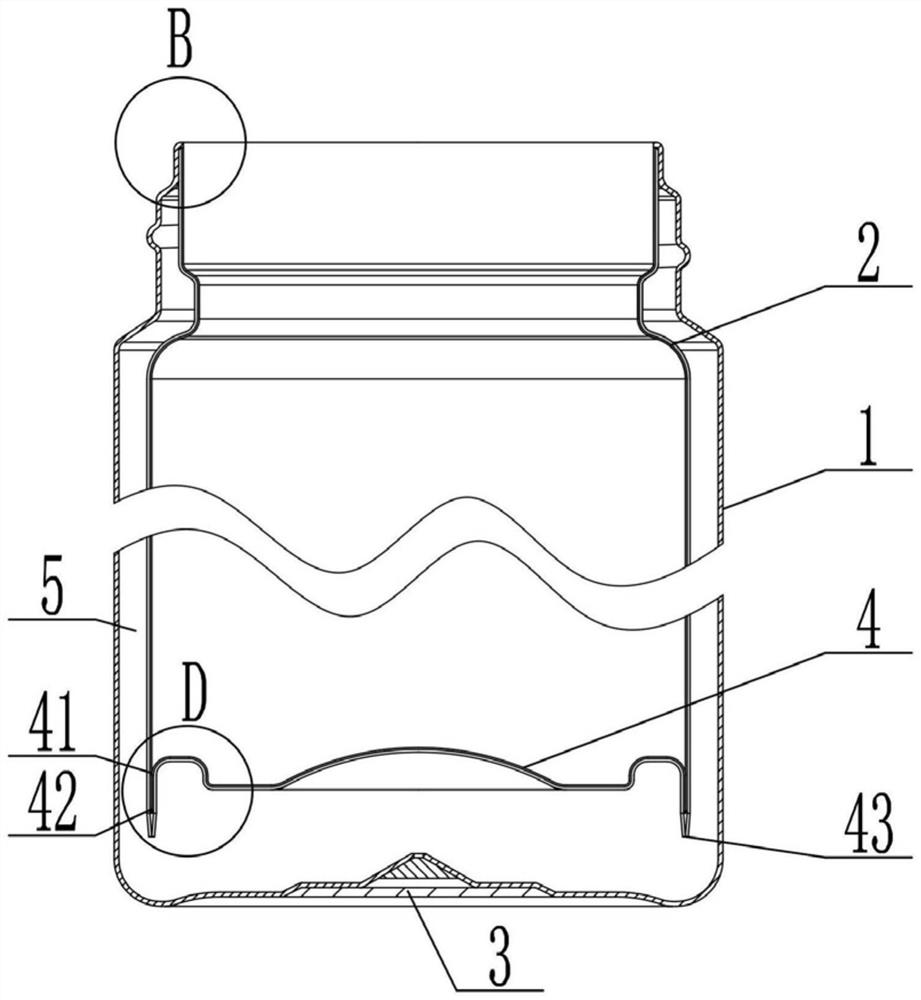

[0077] As a preference, in the step Q7, the mouth of the steel outer layer 23 is shortened first, the end face of the titanium inner layer 22 is higher than the end face of the steel outer layer 23 and forms a 0.5mm step, and then the The stainless steel shell 1 is matched with the mouth, the end face of the mouth of the stainless steel shell 1 is flush with the mouth end face of the steel outer layer 23, and then the mouth of the stainless steel shell 1 is connected with the mouth of the steel outer layer 23. Laser welding, and then the raised steps are bent outwards of the composite liner 2 and welded to the mouth of the stainless steel shell 1 .

[0078] Other implementation modes in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0080] Preferably, the groove 21 has a width of 0.4 mm, and is filled with powdered glass or metal solder for brazing.

[0081] Other implementation modes in this embodiment are the same as those in Embodiments 1-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com