System for normal-temperature desorption treatment of volatile organic compound contaminated soil

A technology of desorption of volatile organic compounds at normal temperature, applied in the restoration of polluted soil, separation of dispersed particles, chemical instruments and methods, etc. Advanced problems, to achieve the effect of reducing the cost of subsequent hazardous waste treatment, increasing the scope of application, and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

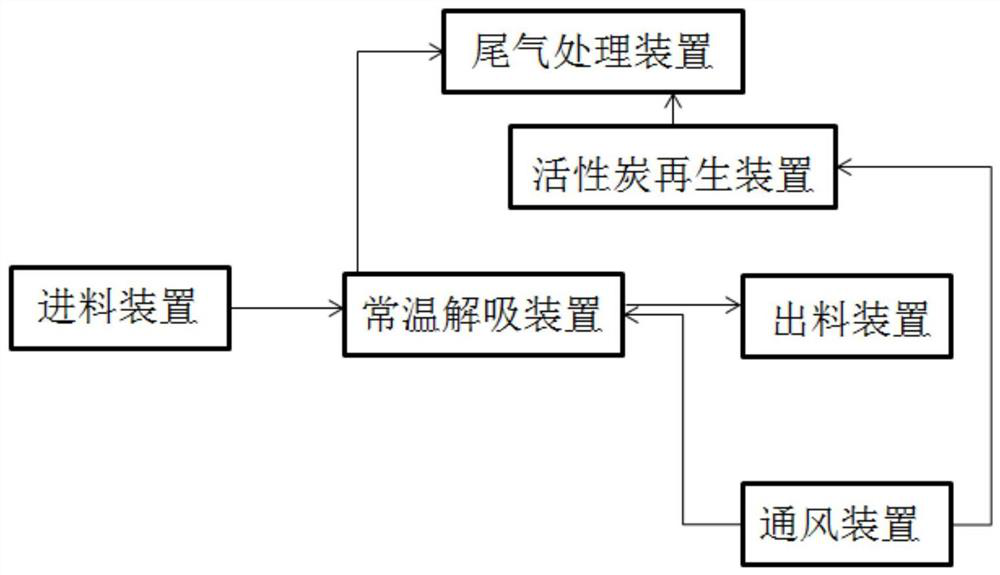

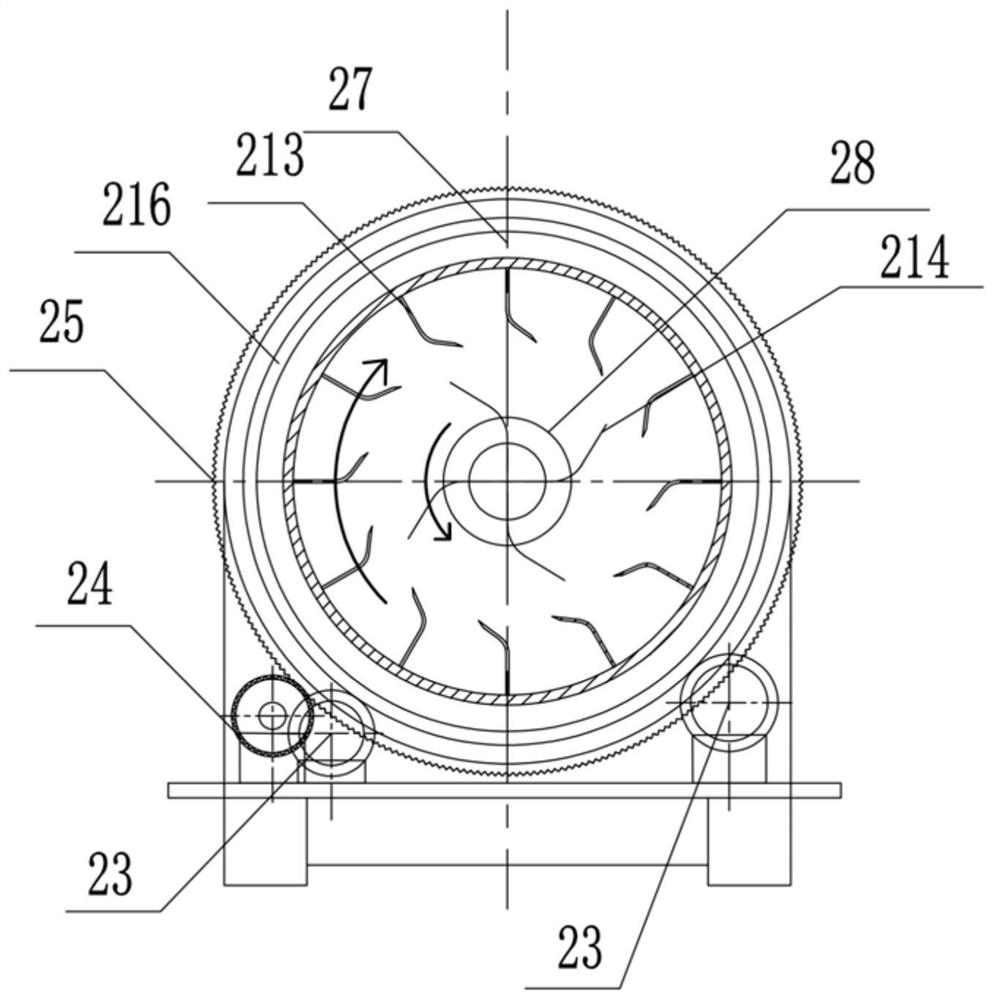

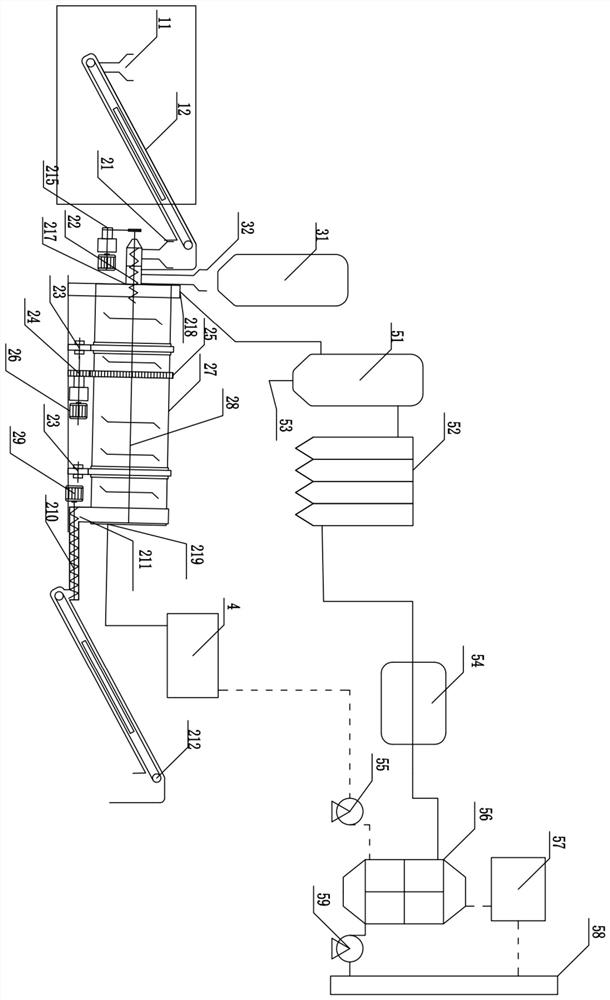

[0061] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a system for strengthening desorption at room temperature to treat soil polluted by volatile organic compounds. The present invention will be further described below in conjunction with the accompanying drawings.

[0062] The invention provides a system for treating volatile organic compound polluted soil by desorption at room temperature, and its working process is as follows: figure 1 As shown, polluted soil and auxiliary materials enter the normal temperature desorption equipment through the feeding device for mixing and stirring, input hot air or dry air through the ventilation device to desorb volatile organic pollutants, the soil is dispensed through the discharge device, and the organic pollutants pass through the tail gas treatment device Deal with up-to-standard emissions. In addition, the fully adsorbed activated carbon is regenerated in situ through the hot air desorption of t...

Embodiment 2

[0081] The method of treating contaminated soil (benzene) of the type of volatile organic compounds (VOCs) using the above system is:

[0082] Include the following steps:

[0083] (1) The contaminated soil and auxiliary materials are input into the normal temperature desorption device through the feeding device, the contaminated soil is rolled and stirred in the cylinder, and moves to the discharge device. The inner diameter of the drum is 1.5m, the length is 15m, the inclination angle is 1.5°, and the drum speed is 2.5r / min , the residence time is 0.5h; the ventilation system blows normal temperature air from the drum vent of the normal temperature desorption device, the air contacts the soil in reverse, desorbs volatile organic compounds, and the desorbed soil is transported to the discharge device and discharged;

[0084] The pollutant content in the soil before desorption is: benzene concentration 47.67mg / kg.

[0085] The soil after desorption needs to meet the requireme...

Embodiment 3

[0094] The ambient temperature is lower than 15°C, and the ethylbenzene-contaminated soil with a moisture content of 35% is treated as follows:

[0095] Include the following steps:

[0096] (1) Input the contaminated soil and auxiliary materials into the normal temperature desorption device through the feeding device, the addition ratio of auxiliary materials is 1~3%, the contaminated soil is rolled and stirred in the drum, and moves to the feeding device; the drum speed is 1.25r / min, and the residence time is 1h. The outer side of the drum is wrapped with an insulation layer. By speeding up the stirring shaft and increasing the disturbance, the ventilation system blows dry air at 40~50°C from the drum vent of the normal temperature desorption device. The air contacts the soil in reverse, desorbs volatile organic compounds, and the desorbed soil Transport to the discharge device and discharge;

[0097] The pollutant content in the soil before desorption is: ethylbenzene conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com