Hydraulic classification recovery method for coal slime

A recovery method and hydraulic classification technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of production shutdown, pipeline blockage failure, affecting the normal production and operation of coal preparation plants, etc., and achieve accurate classification and recovery. Good effect, ensure the effect of normal production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

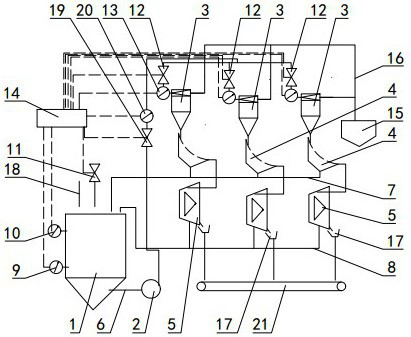

[0019] figure 1 It is the best embodiment of the present invention, below in conjunction with attached figure 1 The present invention will be further described.

[0020] A coal slime hydraulic classification recovery device, including a coal slime tank 1, a hydrocyclone 3, a recovery device and a control cabinet 14, the coal slime outlet of the coal slime tank 1 is connected in series with the coal slime pump 2 and then connected to the input of the hydrocyclone 3 The coal slime outlet of the hydrocyclone 3 is connected with the input port of the recovery device, the water outlet of the recovery device is connected with the top of the slime bucket 1, and the output port of the coal slime pump 2 is connected with the input port of the hydrocyclone 3 An electric valve and a pressure transmitter are sequentially arranged between the ports, and the control cabinet 14 is connected with the electric valve and the pressure transmitter at the same time. The control cabinet 14 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com