Production system and production process of hexamethyldisilazane

A hexamethyldisilazane and production system technology, applied in the field of hexamethyldisilazane production system, can solve problems such as ineffective cleaning, easy pollution of the environment, and inability to add smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

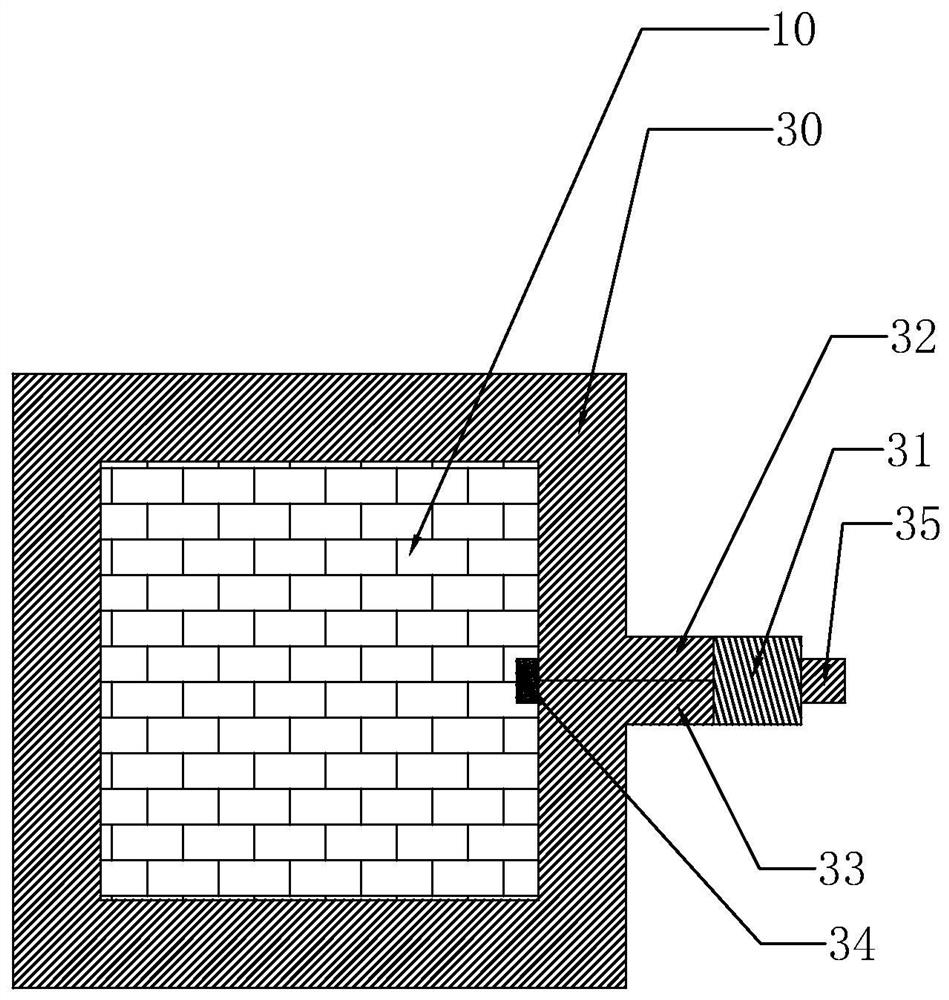

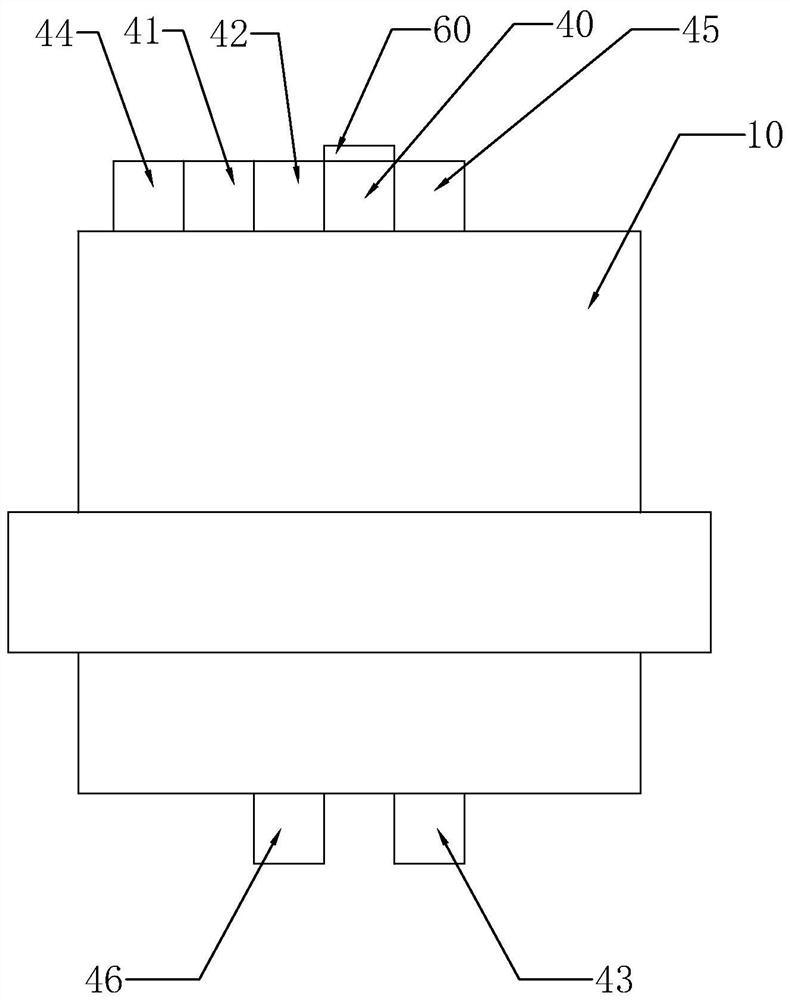

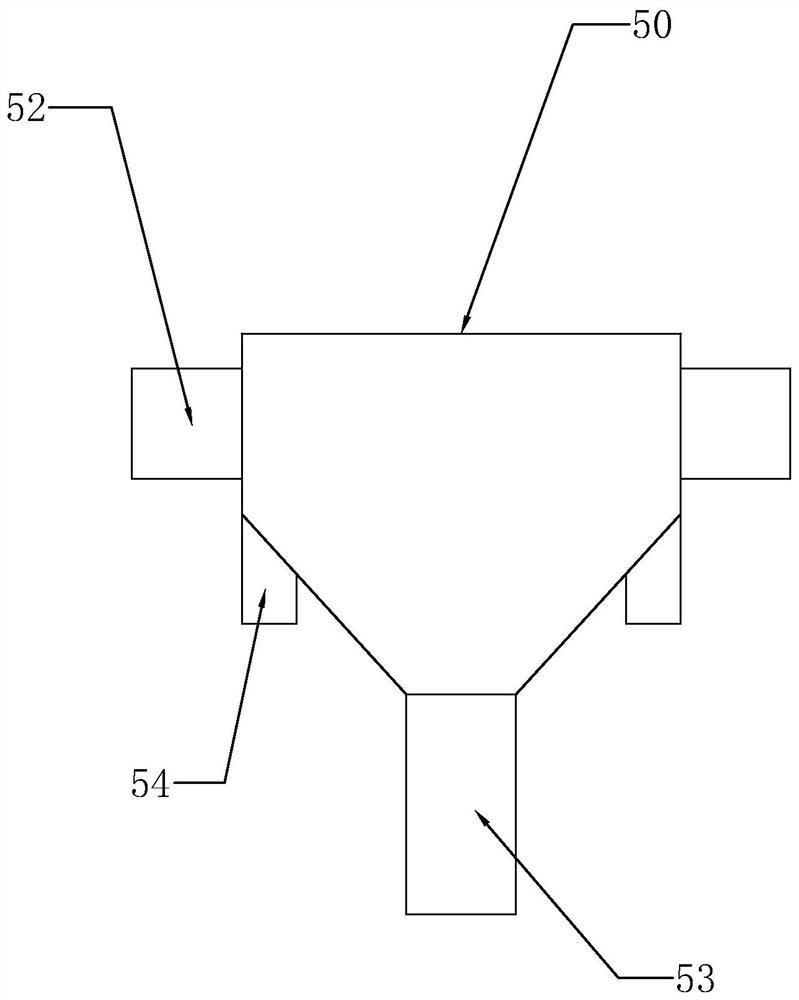

[0036] Such as Figure 1-Figure 3 As shown, the present invention discloses a production system for hexamethyldisilazane, which is characterized in that: it includes a reactor body 10 and a distillation tower 20, and the reactor body 10 and the distillation tower 20 are integrally designed .

[0037] In a specific embodiment of the present invention, a partition wall heat exchanger 30 is provided outside the reactor body 10, and the partition wall heat exchanger 30 includes a high and low temperature circulation pump 31, a first water inlet 32 and a first water outlet 33, the output end of the high and low temperature circulation pump 31 is connected to the first water inlet 32, the input end of the high and low temperature circulation pump 31 is connected to the first water outlet 33, and the reactor body 10 is provided with A temperature sensor 34, the output end of the temperature sensor 34 is connected to a control system 35, and the output end of the control system 35 ...

Embodiment 2

[0041] Embodiment 2 is different from Embodiment 1 in that

[0042] Such as Figure 4-Figure 5 As shown, in a specific embodiment of the present invention, a cleaning system 70 is also provided inside the reactor body 10, and the cleaning system 70 includes a cleaning water tank 71, a heating air pump 72, an exhaust gas purification tower 73, and a chemical waste liquid storage Tank 74, driving device 75 and spray nozzle 76, described driving device 75 comprises motor 751 and rack bar 752, and described motor 751 is arranged on the top of described reactor body body 10, and described motor 751 output end connects described tooth The rack bar 752, the interior of the rack bar 752 is hollow, the side of the rack bar 752 away from the motor 751 is connected to the output end of the water tank and the output end of the heating air pump 72, the rack bar The end of the rod 752 away from the motor 751 is provided with a spray head 76, and the end of the spray head 76 away from the r...

Embodiment 3

[0045] Embodiment 3 is different from Embodiment 2 in that

[0046] Such as Image 6 As shown, in a specific embodiment of the present invention, a stirring device 80 is also provided in the reactor body 10, and the stirring device 80 includes a stirring shaft 81, a stirring motor 82, a stirring fan blade 83 and a controller 84. The controller 84 is connected to the stirring motor 82, the stirring motor 82 is arranged on the top of the reactor body 10, the output end of the stirring motor 82 is connected to the stirring shaft 81, and the stirring shaft 81 is set Stirring blades 83 are arranged, and the stirring blades 83 include an upper stirring blade 821 arranged at the upper section of the stirring shaft, a lower stirring blade 822 arranged at the bottom end of the stirring shaft, and a middle one arranged at the middle section of the stirring shaft 81. Stirring vanes 833, the upper stirring vanes 821, the middle stirring vanes 833 and the lower stirring vanes 822 are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com