high strength steel plate

A high-strength steel plate and plate thickness technology, applied in the direction of metal material coating process, metal layered products, heat treatment furnace, etc., can solve the problems of processability deterioration and achieve the effect of improving bendability and bending load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0181] Hereinafter, specific examples of the present invention will be described using examples. However, the present invention is not limited to the following examples.

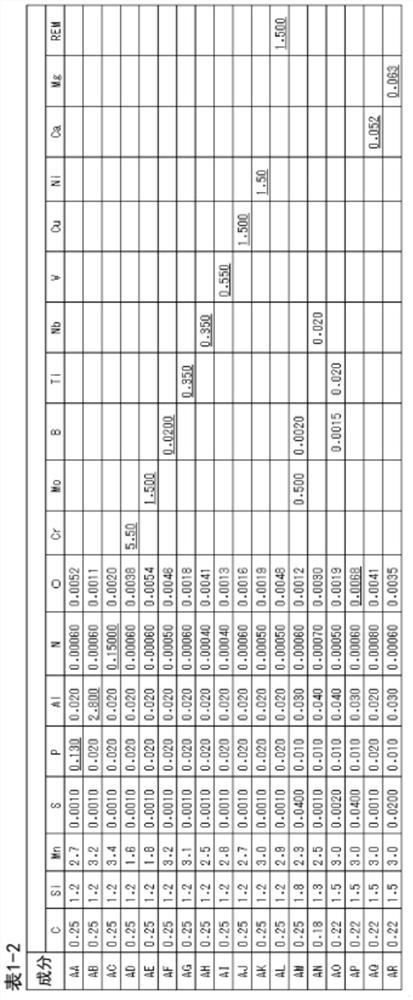

[0182] The cast slabs having the component compositions described in Tables 1-1 and 1-2 were heated to the slab heating temperatures described in Tables 2-1 to 2-3 under the conditions described in Tables 2-1 to 2-3 For hot rolling, coiling. The obtained hot-rolled steel sheet was pickled under the conditions described in Tables 2-1 to 2-3, and used for cold rolling.

[0183] Next, the obtained cold-rolled steel sheets were subjected to annealing treatment under the conditions described in Tables 2-1 to 2-3, some steel sheets were subjected to hot-dip galvanizing by a conventional method, and a portion of the plated steel sheets were further subjected to conventional methods. Alloying treatment is carried out.

[0184] Tables 3-1 to 3-3 show the results of determining the area ratio by identifying the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com