Half-hole plate one-time molding processing method and printed circuit board

A technology of molding processing and half-hole plate, which is applied to printed circuit parts and mechanically removes conductive materials, etc., can solve problems affecting production efficiency, damage to gongs and knives, increase processing flow and production costs, etc., and achieve improvement Accurate speed, improve molding accuracy, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] As an aspect of the embodiment of the present application, there is provided a one-time molding processing method for a half-hole plate, including steps: pretreatment, drilling, copper sinking / plate electrical, outer layer circuit, graphic plating, etching, solder mask, text, surface Processing, forming.

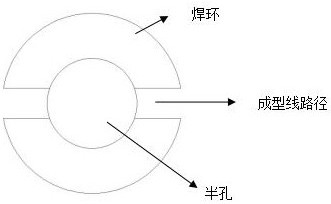

[0068] Wherein, in this example, the etching step uses etching solution to remove the copper on the molding line path in the half-hole solder ring, such as figure 1 shown.

[0069] Wherein, in this example, the molding step includes:

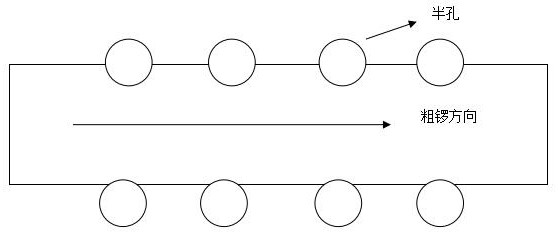

[0070] S100, thick gong: such as figure 2 As shown, the circuit board is slotted through thick holes, and the thick holes are drilled from between the half holes on both sides of the circuit board, and the grooves are not reached during the thick hole.

[0071] S200. Fix the circuit board on the cardboard, and the cardboard is used to support the circuit board.

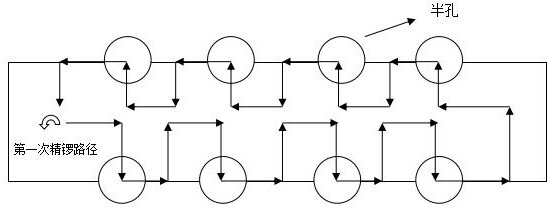

[0072] S300. Carry out the first finishing operation on the circuit b...

Embodiment 2

[0117] As another aspect of the embodiments of the present application, a printed circuit board is provided, which is prepared by the method as described in the first embodiment.

[0118] In summary, the present invention cancels the half-hole process before etching, and completes the half-hole processing in the forming process, and in the process of forming half-holes, the process of forming half-holes is divided into rough and fine, and the fine process is divided into Two times of processing, each fine gong only processes half of the hole wall, avoiding burrs and burrs in the hole when the gong knife cuts the copper layer in the half hole, and avoiding the surface of the printed circuit board before soldering. Hollowing reduces the difficulty of solder mask processing for half-hole plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com