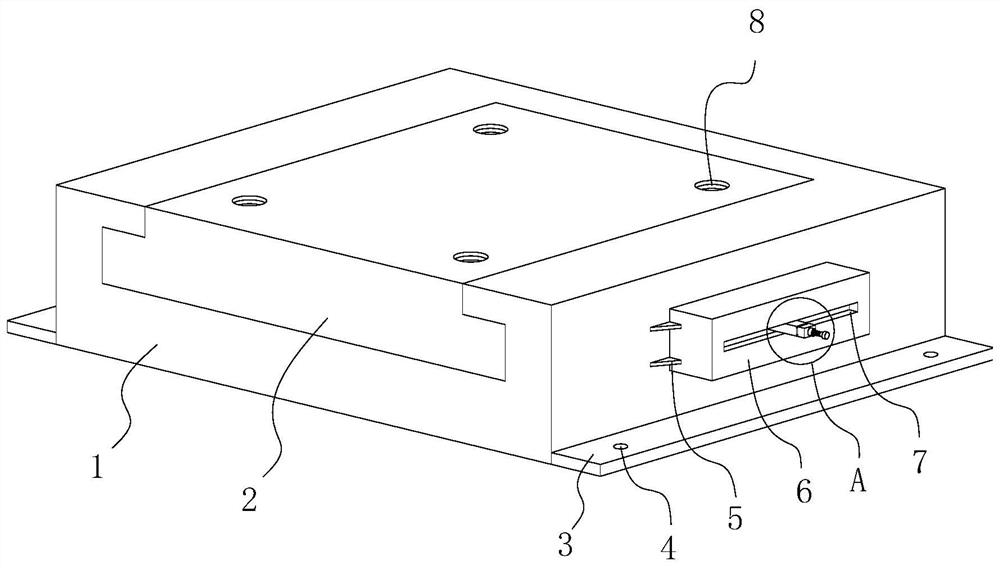

Aviation motor protection frame convenient to install

An aviation motor, easy-to-install technology, applied in electrical components, electromechanical devices, fixtures, etc., can solve problems such as damage to aviation equipment and difficult disassembly, and achieve the effect of convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

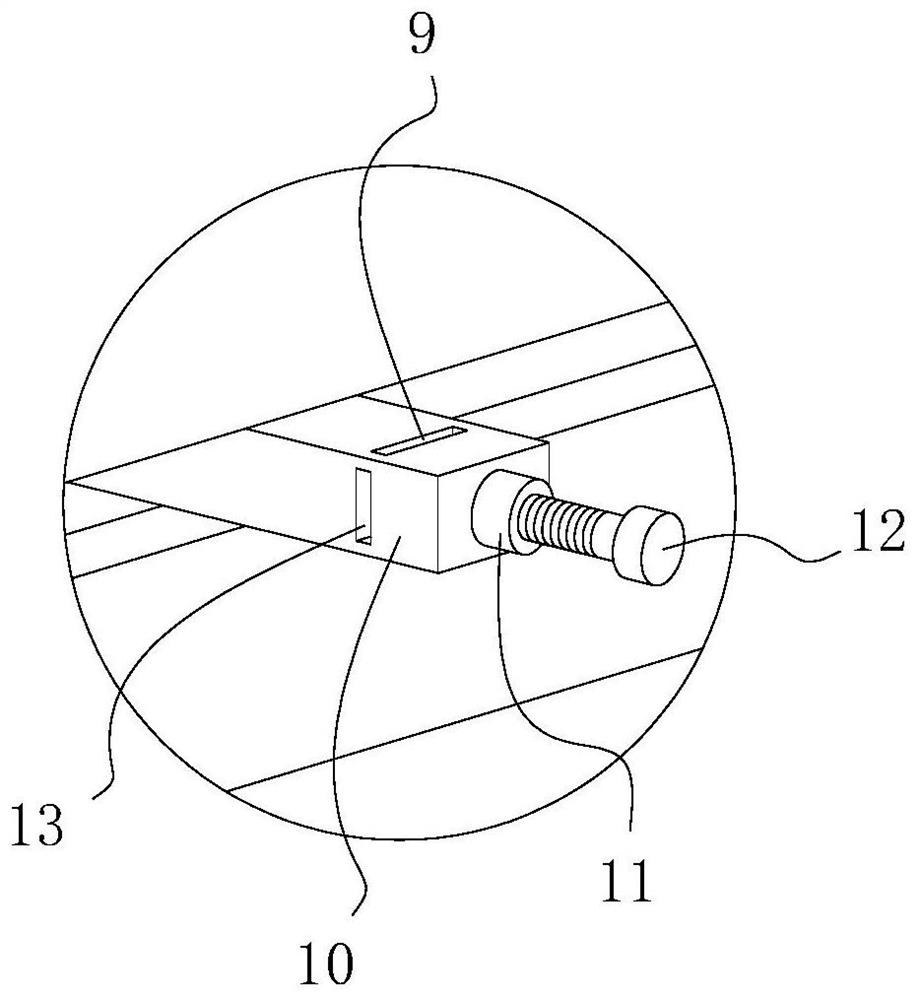

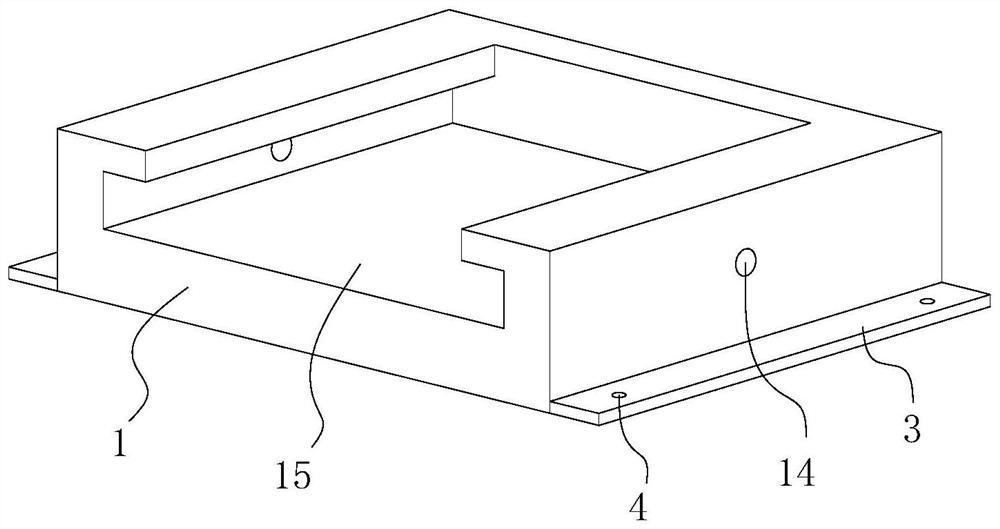

[0042] Specific implementation method: After installing the aviation motor on the support 2, insert the support 2 into the slot 15 on the base 1. After the support 2 is inserted, the pin hole 14 is aligned with the blind hole 28, and along the strip Shape groove 7 stirs square rod 10, and then square rod 10 drives second magnet 21, the 3rd magnet 26 to move by connecting plate 19, when second magnet 21 moves to pin hole 14 places, first magnet 18 and second magnet 21, and then under the action of the attraction force, the end of the pin 17 where the first magnet 18 is installed is inserted in the pin hole 14, so that under the interaction between the pin 17 and the pin hole 14, the support 2 is fixed on the In the base 1, when the bolts fixing the base 1 cannot be disassembled due to corrosion and other reasons, reversely toggle the square rod 10 so that the third magnet 26 is at the pin hole 14, at this time the third magnet 26 and the first magnet 18 repel each other , under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com