Motor stator and permanent magnet synchronous motor

A technology for permanent magnet synchronous motors and motor stators, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, magnetic circuits, etc. volume increase etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

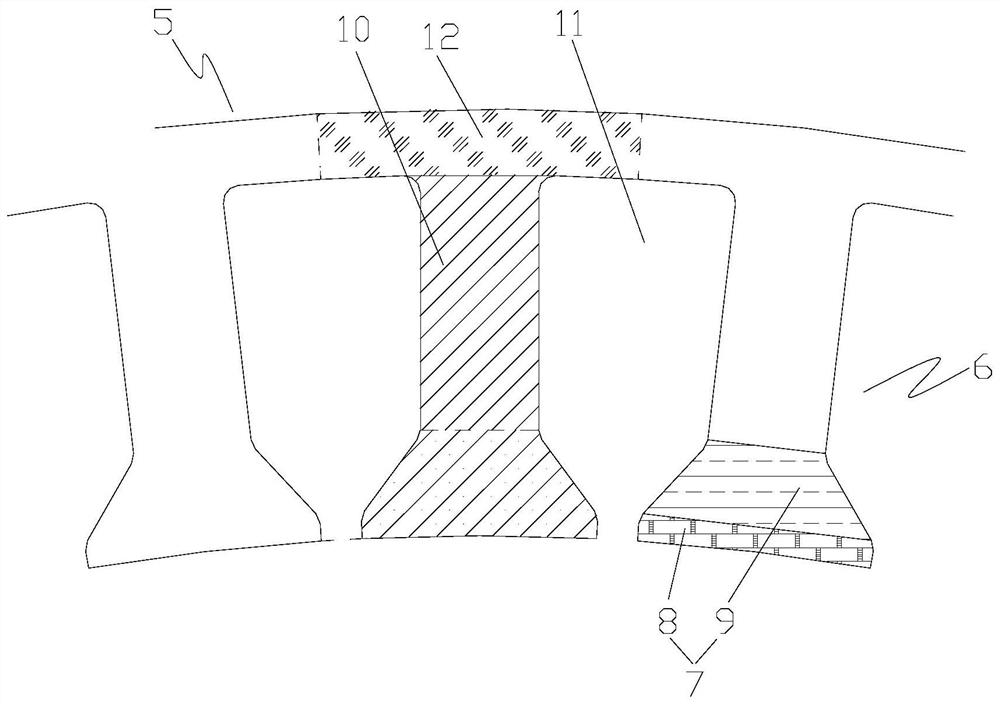

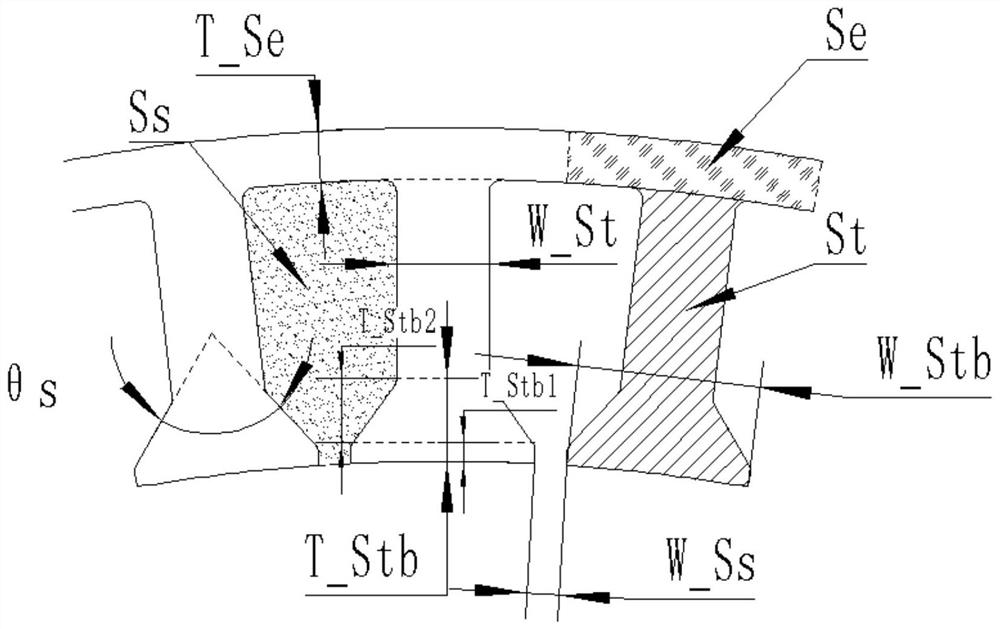

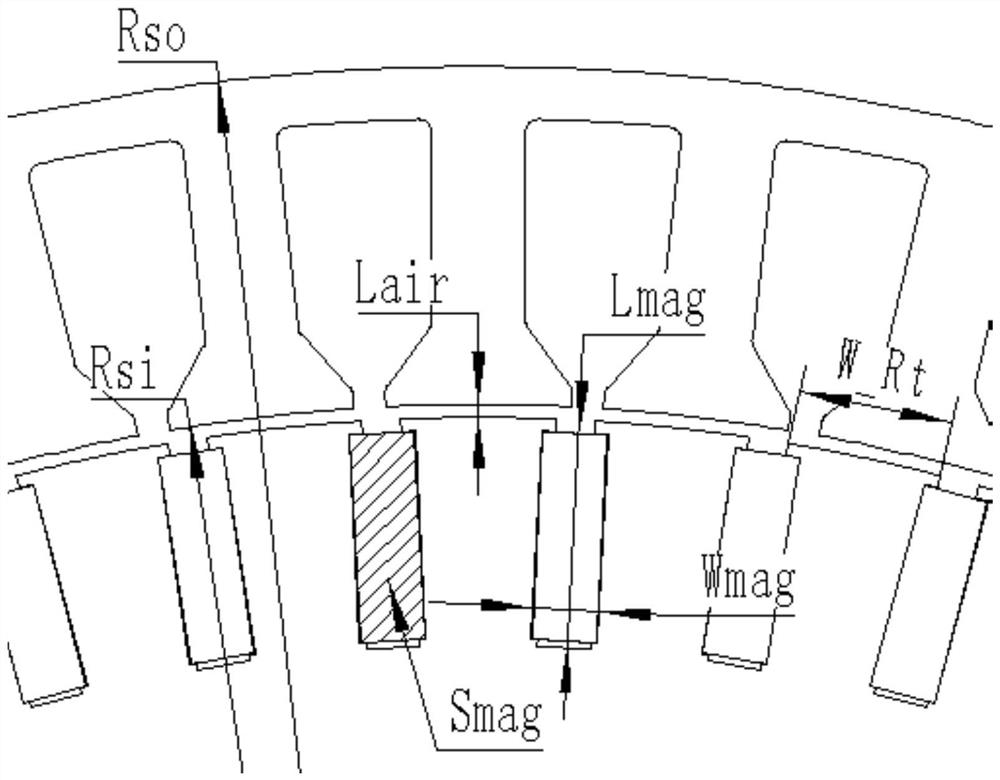

[0040] see in conjunction Figure 1 to Figure 8As shown, according to the embodiment of the present application, the motor stator includes a stator core 5, and the stator core 5 includes a stator tooth portion 6, and the stator tooth portion 6 includes a stator tooth shoe 7. On the cross section of the stator core 5, the stator teeth The shoe 7 sequentially includes a second extension section 9 and a first extension section 8 from outside to inside in the radial direction, and the radial thickness of the second extension section 9 is greater than the radial thickness of the first extension section 8 .

[0041] When the motor is used in low-speed and high-torque applications, it needs to be designed in the form of multi-stage and multi-slot. The magnetic flux leakage on the stator side is much higher than that of conventional motors, which seriously affects performance such as output torque. In view of the above problems, the present application improves the structure of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com