Solar particle reactor with V-shaped groove

A technology of solar energy and reactor, which is applied in the direction of solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of excessive protective gas, lower energy conversion and storage efficiency, and cracking of quartz glass, so as to reduce deposition and simple structure , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

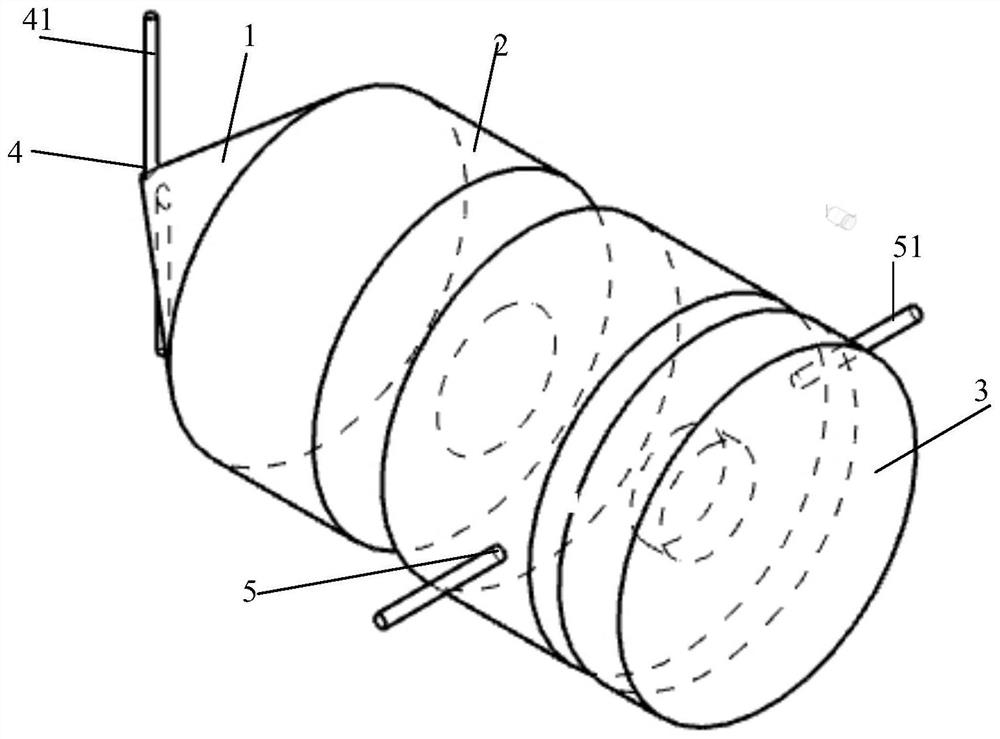

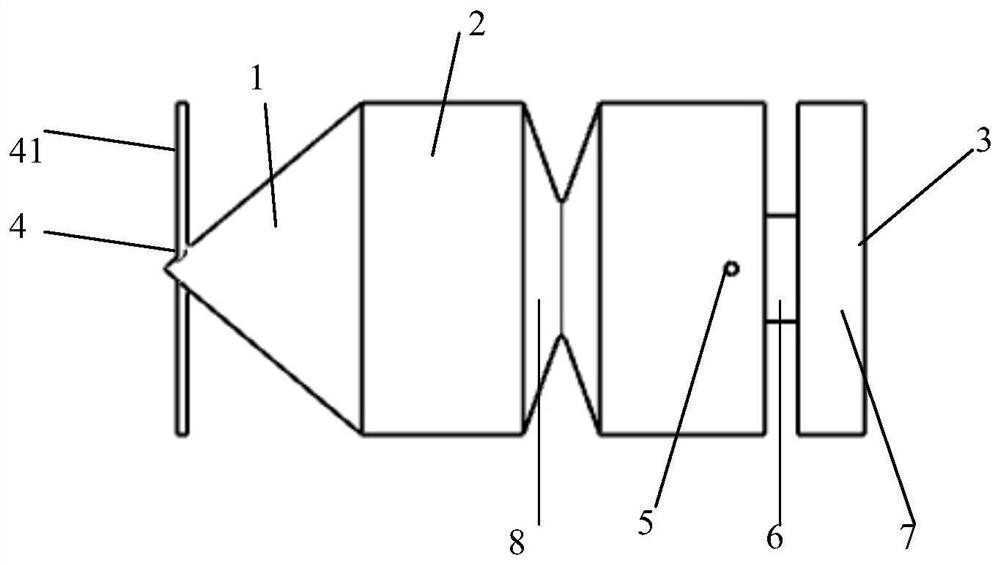

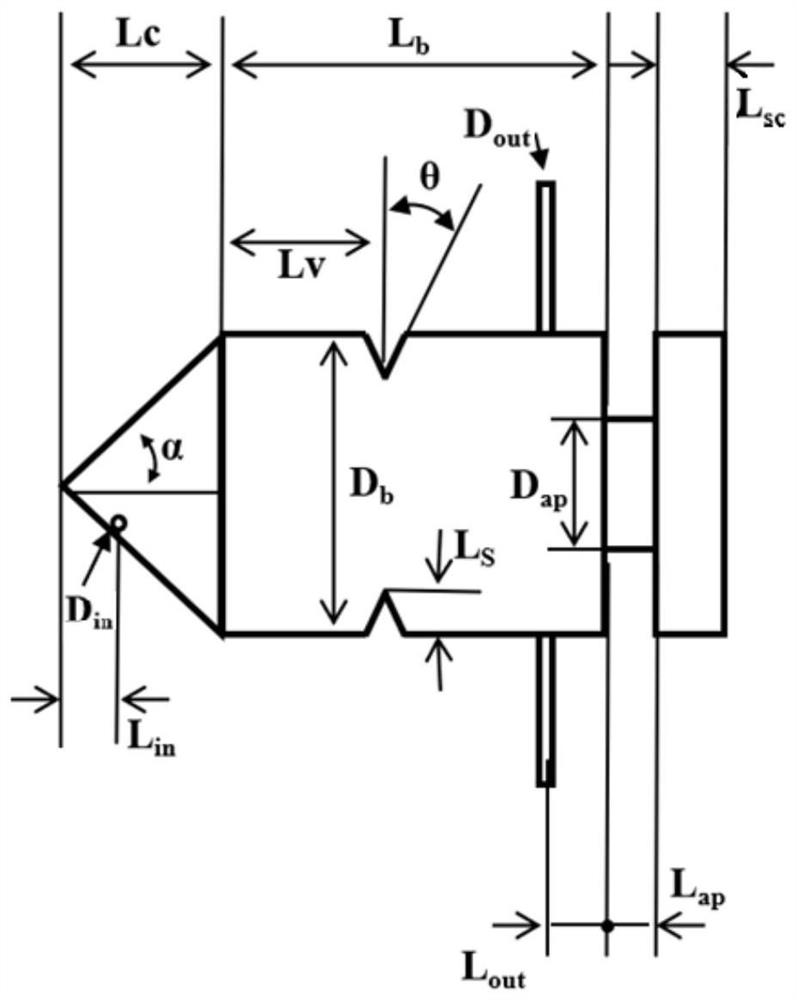

[0024] Such as Figure 1 to Figure 4 As shown, a swirling solar particle reactor invented this time is a reactor for absorbing and decomposing calcium carbonate particles, including a reflow base 1, a reaction chamber 2, a quartz window 3, a small hole channel 6, and a working fluid inlet 4 and working fluid outlet 5, the reaction chamber 2 is a cylinder, the reflux base 1 is a cone, the angle between the busbar of the cone reflux base 1 and the axis is 40°, and the bottom surface of one end of the cylindrical reaction chamber 2 is connected to the bottom surface of the conical reflux base 1 , the top of the reaction chamber 2 is provided with a circular quartz window 3, and the side of the reaction chamber is provided with a V-shaped groove that is sunken to the inside of the reaction chamber. The radial section of the V-shaped groove is V-shaped, and the depth of the V-shaped groove is smaller than the radius of the reaction chamber. The diameter of the bottom surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com