Integrated vector flash explosion soot blower

A soot blowing device and flash explosion technology, which is applied in the fields of solid residue removal, combustion product treatment, and combustion methods, and can solve problems such as equipment blowout, shutdown, and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

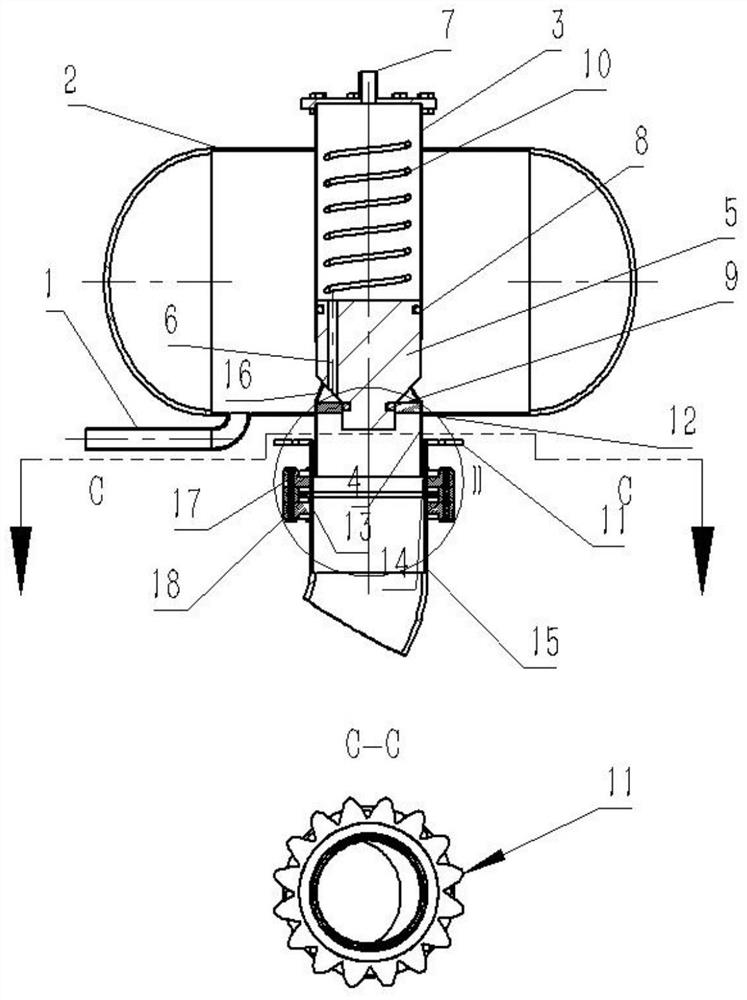

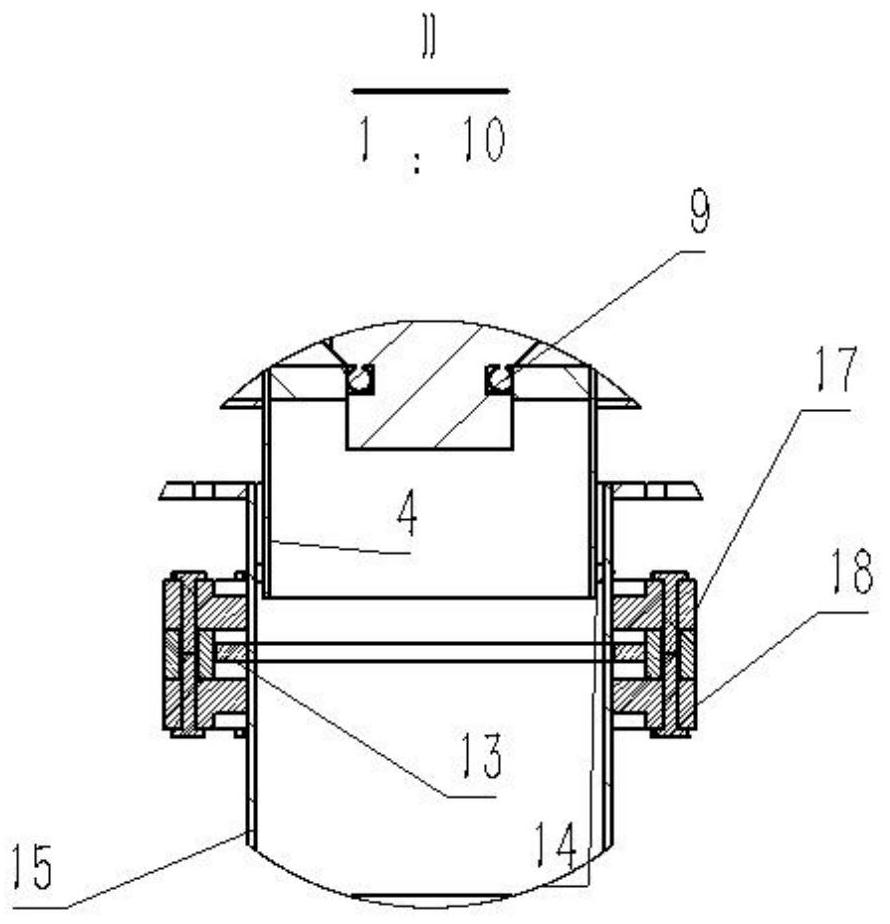

[0007] The present invention is described in further detail below with reference to accompanying drawing:

[0008] Process principle of the present invention and structural principle are described as follows:

[0009] Refer to attached figure 1 , attached figure 2 As shown, the integrated vector flash detonation soot blowing device includes: a flasher and a nozzle, wherein the key component in the flasher is a flash valve; wherein the key component in the nozzle is the vector nozzle 15.

[0010] The flasher is composed of an inlet pipe 1, a flash tank 2, a flash valve and the like.

[0011] Compressed air is selected as the flash explosion medium in this embodiment. The compressed air is very safe and easy to obtain. The compressed air first enters the inlet pipe 1, and then is introduced into the flash explosion tank 2.

[0012] Described flasher is made up of flasher tank 2 and flasher valve.

[0013] And the working principle of the flash valve of the integrated vecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com