Pipe piece dismounting device for waste tunnel expanding and using method thereof

A segment removal and tunneling technology, applied in tunnels, tunnel linings, mining devices, etc., can solve the problems of increased segment removal work limitations, inefficient removal methods, insufficient preparation and consideration, etc., to increase functionality and Convenience of structure adjustment, improve convenience and operability, increase stability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

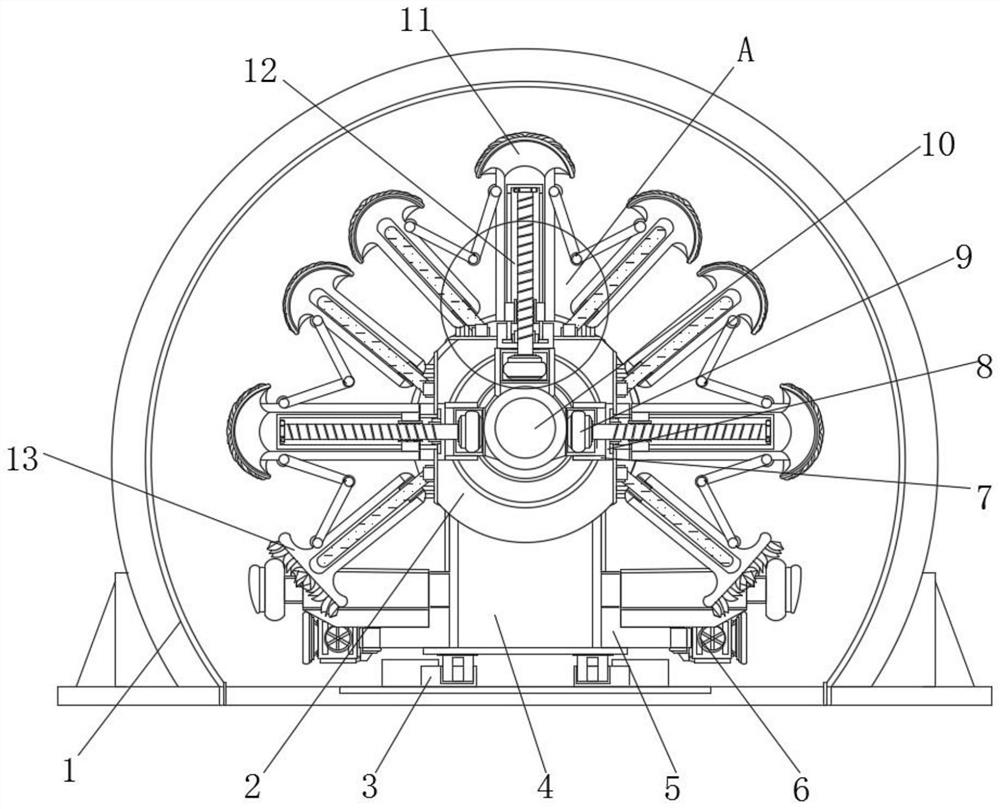

Embodiment 1

[0035] see Figure 1-7 , the present invention provides a technical solution: a segment removal device for expanding the diameter of waste tunnels, comprising a tunnel body 1, a vehicle rail 3 is provided at the middle position of the bottom of the tunnel body 1, and the top of the vehicle rail 3 is provided with mutual The matching car body 4, the bottom of both sides of the car body 4 is provided with L-shaped fixed seats 5 connected to each other, the middle position of the top of the car body 4 is provided with a servo motor B16, and one end of the top of the car body 4 is provided with an annular chute 2 , the middle position of the other end of the top of the car body 4 is provided with a segment bonding assembly, the inner side of the annular chute 2 is provided with three sets of sliding blocks 8 that cooperate with each other, the output end of the servo motor B16 is provided with a rotating shaft 10, and the outer side of the rotating shaft 10 There are three sets of...

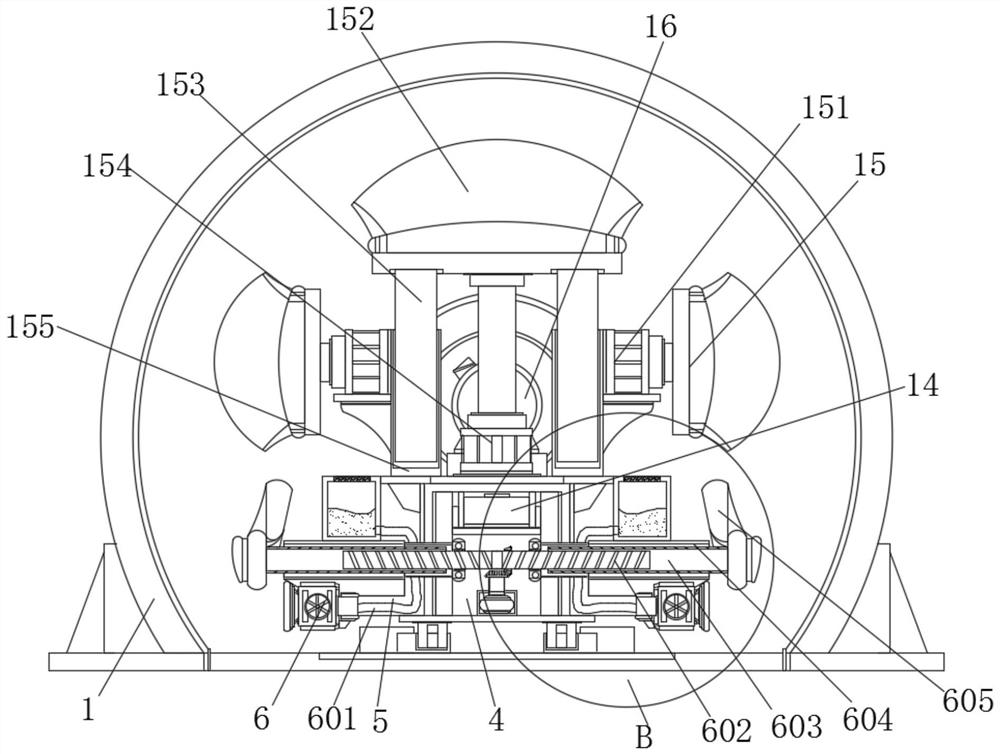

Embodiment 2

[0042] see Figure 1-7 , the present invention provides a technical solution: a segment removal device for expanding the diameter of waste tunnels, comprising a tunnel body 1, a vehicle rail 3 is provided at the middle position of the bottom of the tunnel body 1, and the top of the vehicle rail 3 is provided with mutual The matching car body 4, the bottom of both sides of the car body 4 is provided with L-shaped fixed seats 5 connected to each other, the middle position of the top of the car body 4 is provided with a servo motor B16, and one end of the top of the car body 4 is provided with an annular chute 2 , the middle position of the other end of the top of the car body 4 is provided with a segment bonding assembly, the inner side of the annular chute 2 is provided with three sets of sliding blocks 8 that cooperate with each other, the output end of the servo motor B16 is provided with a rotating shaft 10, and the outer side of the rotating shaft 10 There are three sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com