Light preset assembly type space net rack ribbed floor formwork and construction process

A floor formwork and prefabricated technology, applied in the direction of formwork/formwork/work frame, floor slab, building components, etc., can solve the problems of easy displacement of formwork, uneven width, reduction or reduction of formwork consumption, etc., to achieve increased size Accuracy, reduce the overall cost, and improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

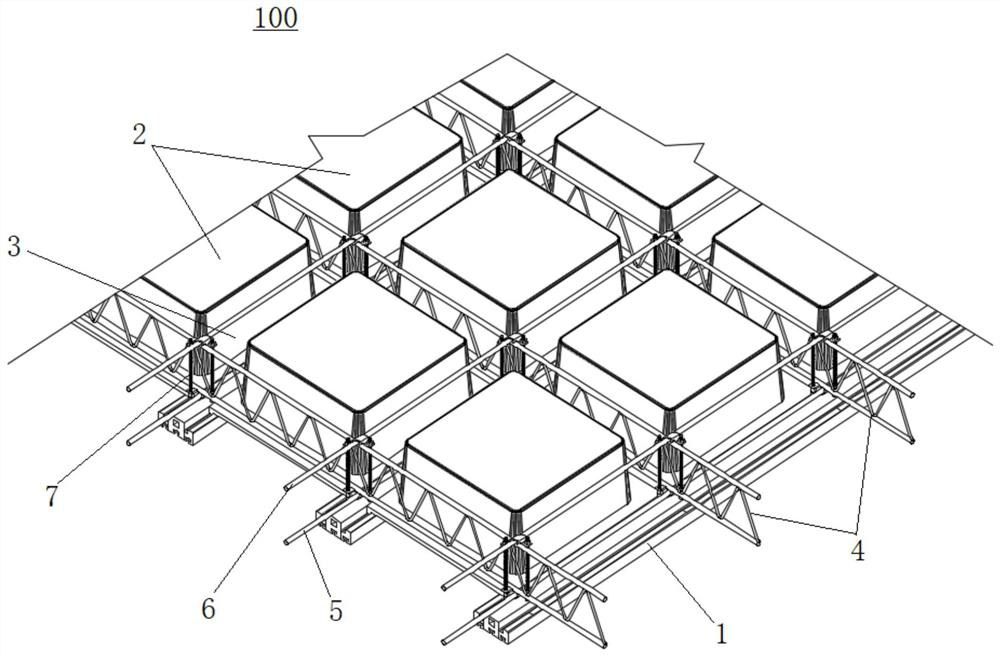

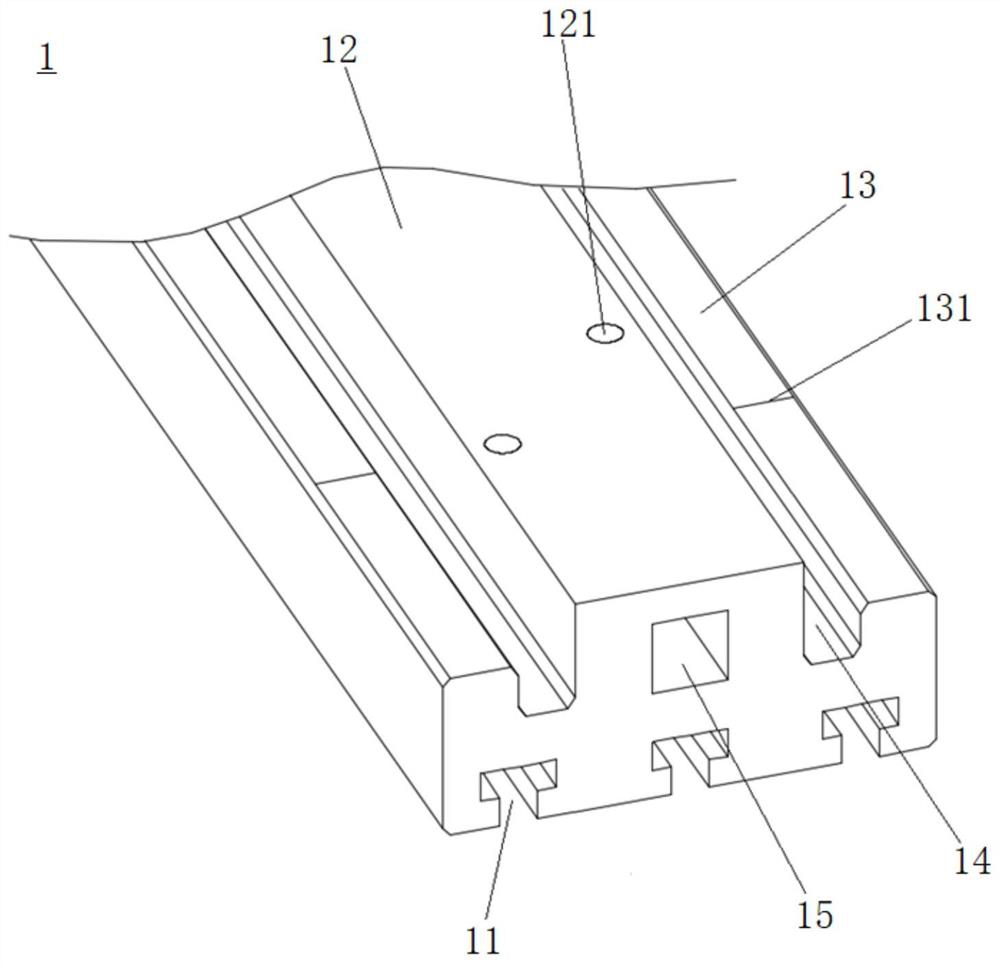

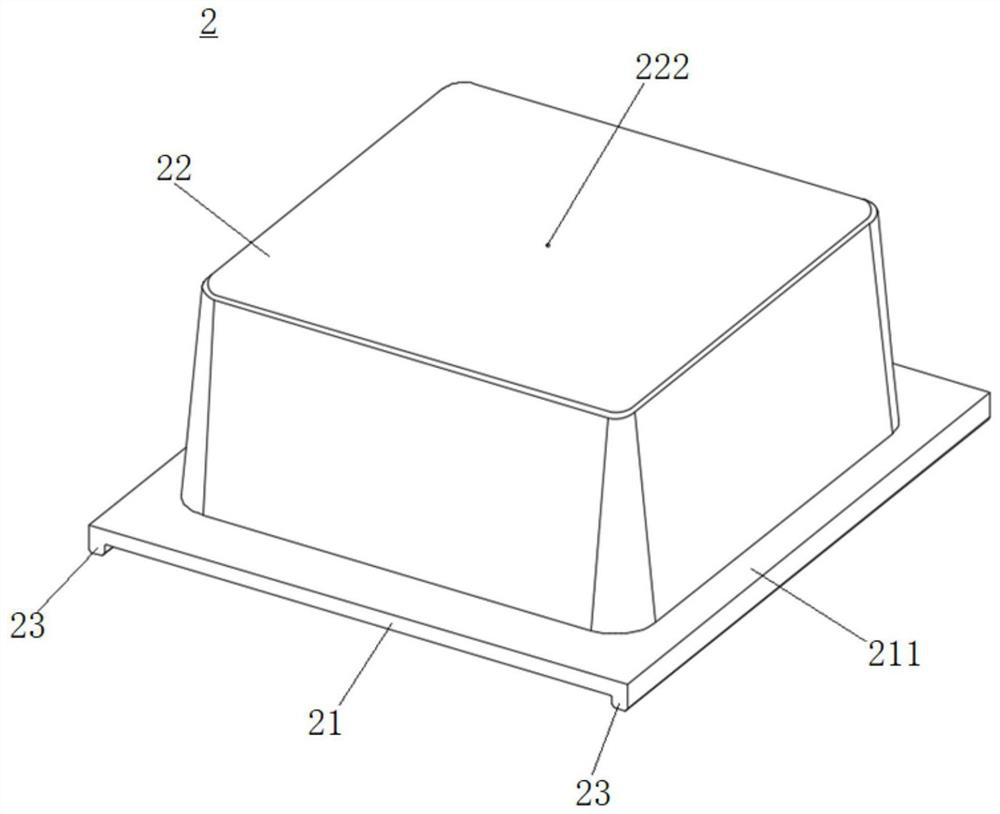

[0043] Please refer to Figure 1-Figure 11 In this embodiment, a light-duty prefabricated space grid ribbed floor formwork 100 includes a plurality of metal keels 1 arranged in parallel and spaced apart, and a plurality of formwork 2 built on two adjacent metal keels 1 on both sides, adjacent to each other. Formwork shells 2 in the same row between two metal keels 1 are arranged one by one without gaps, and rib beam grooves 3 are formed in a criss-cross pattern between all formwork shells 2 and metal keel 1, and rib beam grooves 3 in the same row are provided with metal The truss unit 4 vertically distributed on the keel 1, the lower longitudinal rib 5 and the upper longitudinal rib 6 parallel to the metal keel 1 are arranged in the rib beam groove 3 in the same row, the metal keel 1 is locked with a truss connector 7, and the truss unit 4 , The lower longitudinal rib 5 and the upper longitudinal rib 6 are detachably locked on the metal keel 1 through the truss connector 7 as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com