Method for modifying high-performance carbon paper based on supercritical fluid technology

A supercritical fluid, high-performance technology, used in paper, papermaking, specialty paper, etc., can solve the problems of difficulty in controlling the depth of gas phase oxidation, reducing oxidation time, and insignificant modification effect of a single titanate coupling agent. Molecular movement is intense, the oxidation time is reduced, and the penetration ability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

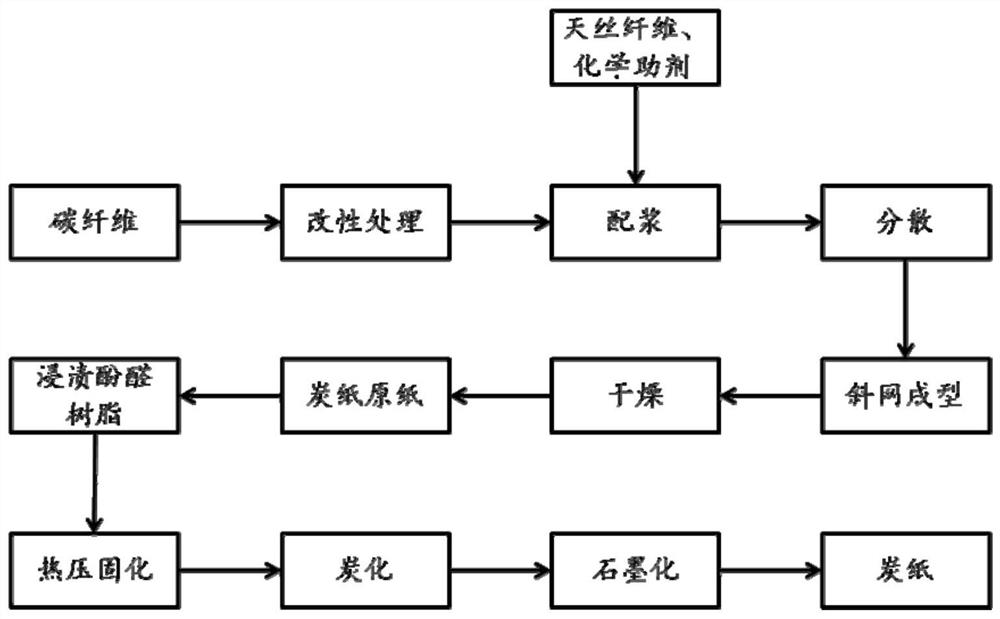

Image

Examples

Embodiment 1

[0042] Put the carbon fiber in acetone, the amount of acetone used is 60ml / 1g of carbon fiber, extract it in a Soxhlet extractor at 80°C for 10h, wash it with distilled water until it is neutral, and dry it in an oven at 90°C for 3h; the cleaned carbon fiber Place in supercritical water reactor, add oxygen, reaction time 20min, reaction temperature 400°C, reaction pressure 25MPa, then dry in 90°C oven for 3h; put oxidized carbon fiber into 3% titanic acid Ester coupling agent TMC-311 in methanol solution, and placed in a supercritical water reactor, the temperature is controlled at 400 ° C, the pressure is 25 MPa, and the reaction time is 30 minutes; after the reaction, the carbon fiber is washed in supercritical water for 3 times. Then the carbon fiber was dried in an oven at 90° C. for 3 hours to obtain the modified carbon fiber.

[0043] Add 90 parts by mass of modified carbon fiber and 10 parts by mass of Tencel fiber into a mixing tank, add water to mix, and stir to make ...

Embodiment 2

[0046] Put the carbon fiber in acetone, the amount of acetone used is 40ml / 1g of carbon fiber, extract it in a Soxhlet extractor at 75°C for 15h, wash it with distilled water until it is neutral, and dry it in an oven at 80°C for 4h; the cleaned carbon fiber Put it in a supercritical water reactor, add oxygen, react for 15 minutes, react at a temperature of 380°C, and react at a pressure of 30MPa, and then dry it in an oven at 80°C for 4 hours; put the oxidized carbon fiber into a mass fraction of 2% titanic acid Ester coupling agent TMC-114 in methanol solution, and placed in a supercritical water reactor, the temperature is controlled at 380 ° C, the pressure is 30 MPa, and the reaction time is 25 minutes; after the reaction, the carbon fiber is washed in supercritical water for 4 times. Then the carbon fibers were dried in an oven at 80° C. for 4 hours to obtain modified carbon fibers.

[0047] Add 85 parts by mass of modified carbon fiber and 15 parts by mass of Tencel fib...

Embodiment 3

[0050] Put the carbon fiber in acetone, the amount of acetone used is 80ml / 1g of carbon fiber, extract it in a Soxhlet extractor at 85°C for 20h, wash it with distilled water until it is neutral, and dry it in an oven at 100°C for 2h; the cleaned carbon fiber Place in a supercritical water reactor, add oxygen, react for 10 minutes, react at a temperature of 450°C, and react at a pressure of 35MPa, then dry in an oven at 100°C for 2 hours; put the oxidized carbon fiber into a mass fraction of 1% titanic acid Ester coupling agent TMC-201 in methanol solution, and placed in a supercritical water reactor, the temperature is controlled at 450 ° C, the pressure is 35 MPa, and the reaction time is 20 minutes; after the reaction, the carbon fiber is washed in supercritical water for 5 times. Then the carbon fibers were dried in an oven at 100° C. for 2 hours to obtain modified carbon fibers.

[0051] Add 95 parts by mass of modified carbon fiber and 5 parts by mass of Tencel fiber int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com