A multi-level catalytic structure composite material for efficient electrolysis of water and hydrogen evolution and its preparation method

A technology of composite materials and electrolysis of water, which is applied in the field of electrocatalytic material preparation, can solve the problems of further improvement of catalytic hydrogen evolution performance, uneven distribution of catalytic active sites, low activity of catalytic sites, etc., to achieve controllable growth, low Effect of low overpotential and raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of the multi-level structure composite material used for high-efficiency electrolysis of water and hydrogen evolution of the present invention comprises the following steps:

[0058] 1) Take the raw material Co(NO 3 ) 2 ·6H 2 O, 2-methylimidazole and methanol;

[0059] Among them, Co(NO 3 ) 2 ·6H 2 O was used as the Co source, 2-methylimidazole provided the organic ligand, and methanol was used as the organic solvent to prepare the metal-organic framework ZIF-67, in which Co(NO 3 ) 2 ·6H 2 O and 2-methylimidazole were respectively dissolved in methanol and then mixed, and the Co(NO 3 ) 2 ·6H 2 The molar concentration of O is 40-60 mmol / L, and the molar concentration of 2-methylimidazole is 110-130 mmol / L.

[0060] 2) Co(NO 3 ) 2 ·6H 2 After mixing O, 2-methylimidazole and methanol, first stir at a rate of 1000-1200 rpm for 5-10 min, then slowly stir at a rate of 300-500 rpm for 3-6 h, filter by vacuum filtration, and use methanol Ce...

Embodiment 1

[0066] In this embodiment, the method for preparing a multi-level structure composite material for high-efficiency electrolysis of water and hydrogen evolution includes the following steps:

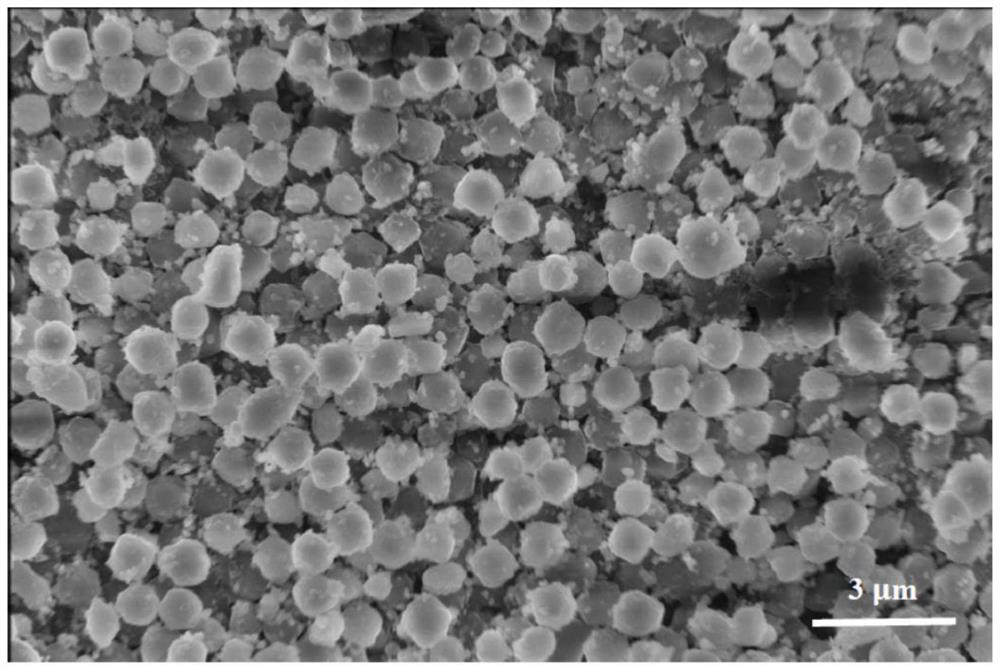

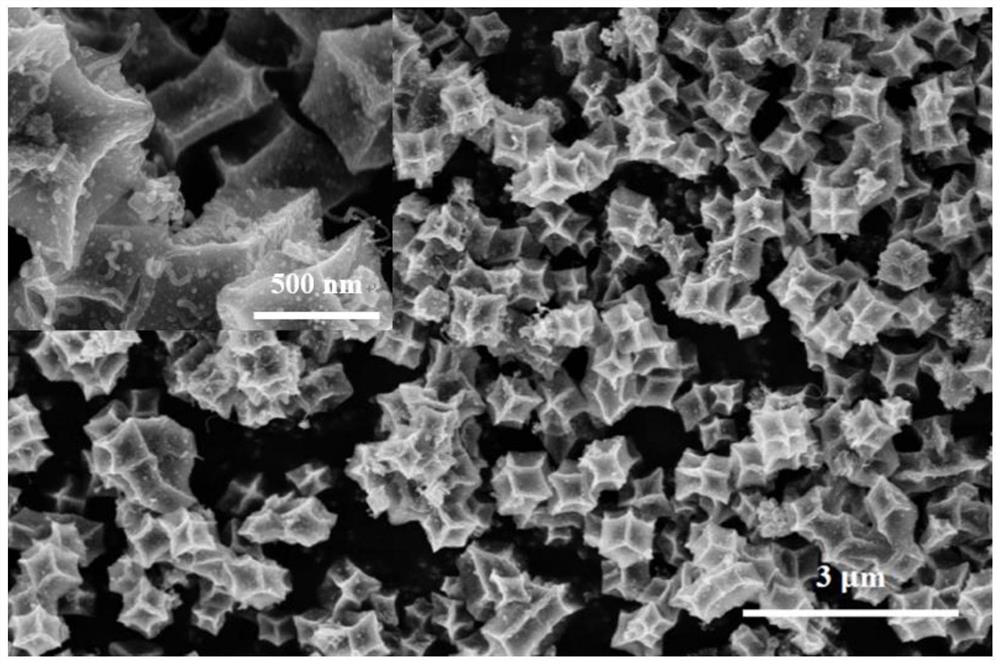

[0067] 1) Take the raw material Co(NO 3 ) 2 ·6H 2O, 2-methylimidazole and methanol, weigh 4.66 g of Co(NO 3 ) 2 ·6H 2 O and 3.94 g of 2-methylimidazole were added to 200 ml of methanol, stirred at a rate of 1000 rpm for 10 minutes and then ultrasonically dissolved for 5 minutes, and the methanol solution containing cobalt nitrate was poured into the methanol solution containing 2-methylimidazole , stirred at 1000 rpm for 5 min, then slowly stirred at 300 rpm for 4 h, filtered by vacuum filtration, washed with methanol for 3 times, and finally placed in a vacuum oven at 60 °C for 24 h to obtain ZIF-67 Powder. The microscopic appearance of gained ZIF-67 powder is as follows figure 1 As shown, the generally dodecahedral large particles (~1 μm) have a rough surface and are loaded with ...

Embodiment 2

[0074] In this embodiment, the method for preparing a multi-level structure composite material for high-efficiency electrolysis of water and hydrogen evolution includes the following steps:

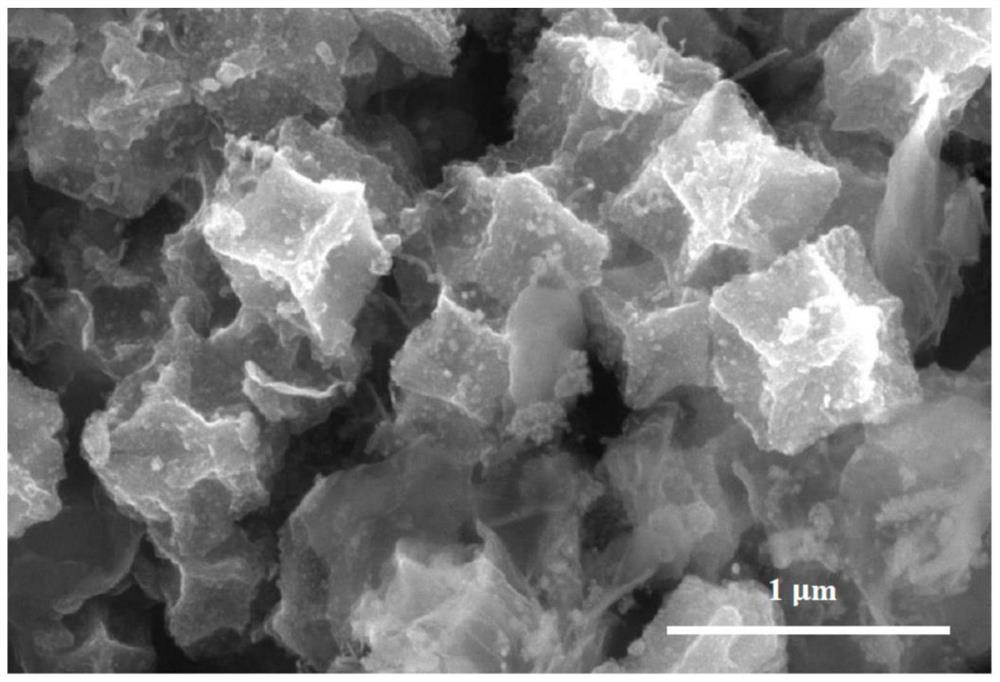

[0075] 1) Take the raw material Co(NO 3 ) 2 ·6H 2 O, 2-methylimidazole and methanol, weigh 5.82 g of Co(NO 3 ) 2 ·6H 2 O and 3.61 g of 2-methylimidazole were added to 200 ml of methanol respectively, stirred at a rate of 1100 rpm for 10 min and then ultrasonically dissolved for 5 min, and the methanol solution containing cobalt nitrate was poured into the methanol containing 2-methylimidazole The solution was stirred at 1100 rpm for 10 min, then slowly stirred at 400 rpm for 3 h, filtered by vacuum filtration, washed with methanol for 3 times, and finally placed in a vacuum oven at 80 °C for 18 h to obtain ZIF- 67 powder. The microscopic appearance of gained ZIF-67 powder is as follows Figure 8 As shown, the surface of large particles (~1 μm) is rough and loaded with small particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com