Low-molecular-weight polyurethane resin and application thereof in tackifying resin

A polyurethane resin, low molecular weight technology, applied to low molecular weight polyurethane resin and its application in tackifying resin, can solve the problems of no active group, inability to disperse, bulk crosslinking, etc., to control side reactions, reduce Condensation of reaction heat, the effect of slowing down the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

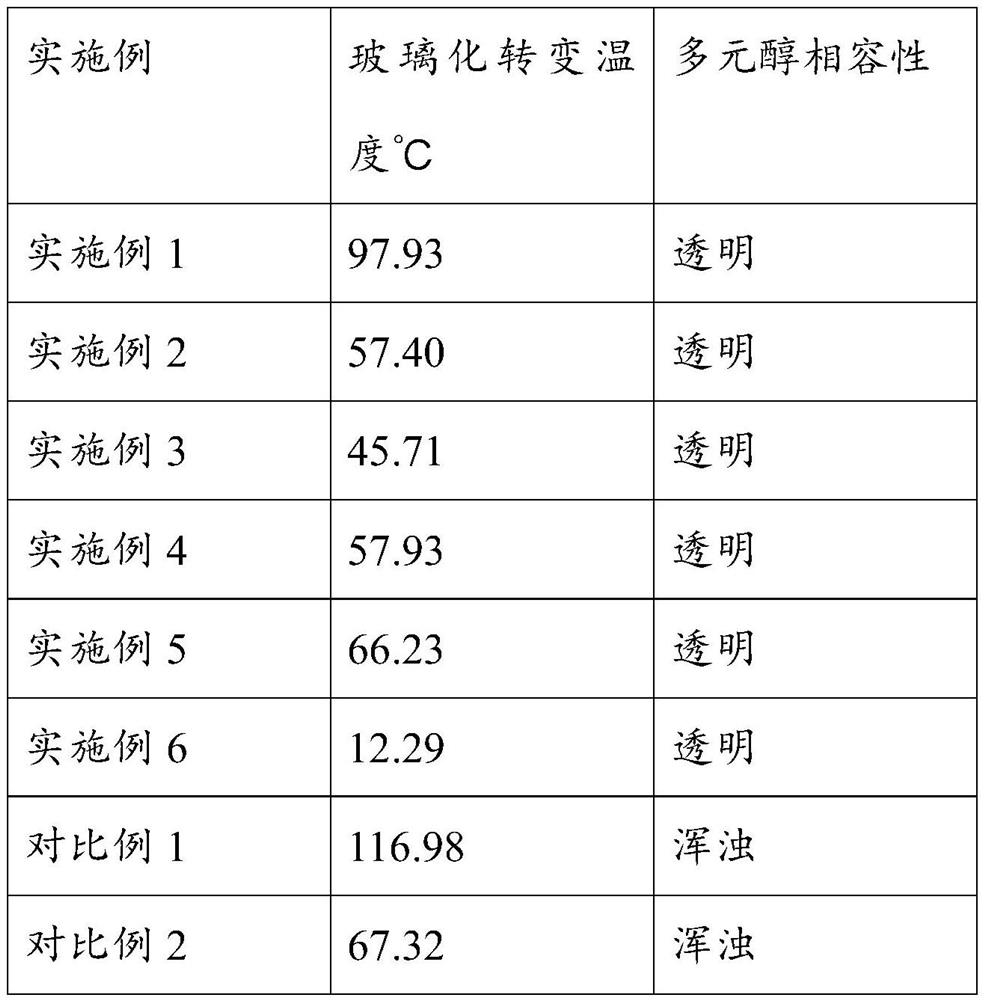

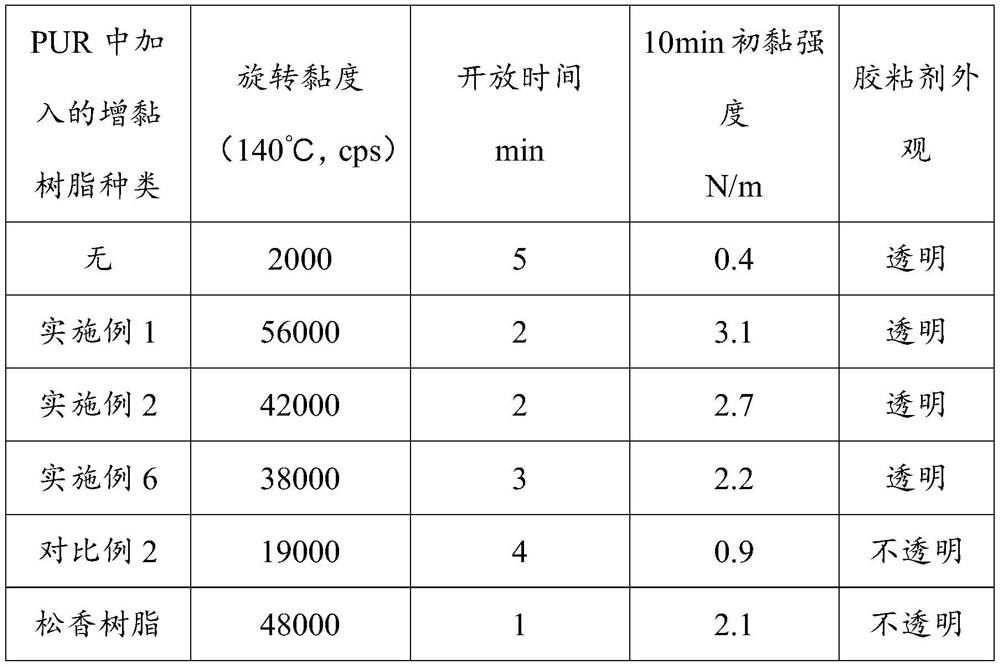

Examples

Embodiment 1

[0043] Add 62.78g of 2-methyl-1,3-propanediol into the reaction vessel, protect it with nitrogen, stir and heat to 110°C, and vacuum above 0.099MPa to remove water for 2h. Lower the temperature of 2-methyl-1,3 propanediol to 60°C, stir at a speed of 550r / min, add 137.63g of diisocyanate three times, and wait for the temperature to drop below 70°C after each addition before adding the next one. After the addition is complete, the temperature is 80°C and the reaction is stirred for 2 hours, and then the finished product is obtained.

Embodiment 2

[0045] Add 127.34g of diethylene glycol into the reaction vessel, protect it with nitrogen gas, stir and heat to 110°C, and vacuum above 0.099MPa to remove water for 2h. Lower the temperature of diethylene glycol to 60°C, stir at a speed of 550r / min, and add 250.24g of diisocyanate three times. After each addition, wait for the temperature to drop below 70°C before adding the next time. After the addition is complete, the temperature is 80°C and the reaction is stirred for 2 hours, and then the finished product is obtained.

Embodiment 3

[0047] Add 90.10 g of triethylene glycol into the reaction vessel, protect it with nitrogen, stir and heat to 110° C., and vacuumize above 0.099 MPa to remove water for 2 hours. Lower the temperature of triethylene glycol to 60°C, stir at a speed of 550r / min, add 125.12g of diisocyanate three times, and wait for the temperature to drop below 70°C after each addition before adding the next time. After the addition is complete, the temperature is 80°C and the reaction is stirred for 2 hours, and then the finished product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com