Silicon carbide hot melt solid repairing paste and preparation method thereof, and blast furnace and submerged arc furnace taphole repair method

A silicon carbide heat and tap hole technology, applied in lighting and heating equipment, furnace, lining repair and other directions, can solve the problems of construction tap hole shape limitation, complicated construction, slag hanging on tap hole, etc. Hanging slag and hanging iron, with reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

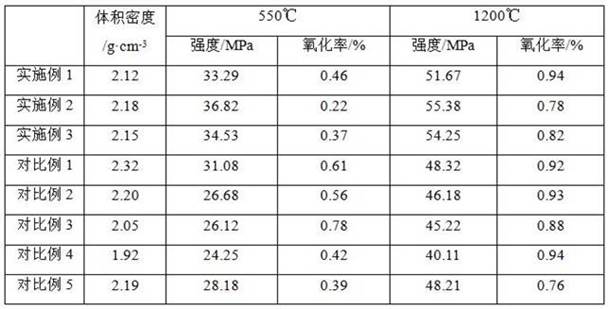

Examples

preparation example Construction

[0030] The embodiment of the present invention also provides a method for preparing the above-mentioned silicon carbide hot-melt repair paste, which includes:

[0031] S1. Mix the first silicon carbide powder, the second silicon carbide powder, and the third silicon carbide powder in proportion to obtain silicon carbide powder;

[0032] S2. uniformly mixing silicon carbide powder, graphite powder and metal silicon powder to obtain a mixed powder;

[0033] S3. Knead the mixed powder with medium temperature modified asphalt and anthracene oil.

[0034] Preferably, the kneading temperature is 80-100° C., and the kneading time is 1-2 h. After mixing well, let it cool and pack it into bags.

[0035] The embodiment of the present invention also provides a method for repairing the taphole of a blast furnace and a submerged arc furnace, which includes:

[0036] S1. Place a steel pipe with the same diameter as the taphole in the taphole of the blast furnace and submerged arc furnace...

Embodiment 1

[0044] This embodiment provides a silicon carbide hot-melt repair paste, which includes:

[0045] 60 parts of silicon carbide powder, 10 parts of graphite powder, 2 parts of metal silicon powder, 20 parts of medium temperature modified asphalt, 5 parts of anthracene oil;

[0046] Wherein, the silicon carbide powder includes the first silicon carbide powder, the second silicon carbide powder, and the third silicon carbide powder; the particle diameter of the first silicon carbide powder is 1~3 mm, and the particle diameter of the second silicon carbide powder is 0.08~ 1 mm; the particle size of the third silicon carbide powder is <0.08 mm; the mass ratio of the first silicon carbide powder, the second silicon carbide powder, and the third silicon carbide powder is 1:2.2:1.8. The particle size of graphite powder is 0.05~1mm. The particle size of metal silicon powder is 0.05~1 mm.

[0047] The preparation method of the silicon carbide hot-melt repair paste is as follows:

[00...

Embodiment 2

[0052] This embodiment provides a silicon carbide hot-melt repair paste, which includes:

[0053] 65 parts of silicon carbide powder, 5 parts of graphite powder, 5 parts of metal silicon powder, 15 parts of medium temperature modified asphalt, 10 parts of anthracene oil;

[0054] Wherein, the silicon carbide powder includes the first silicon carbide powder, the second silicon carbide powder, and the third silicon carbide powder; the particle diameter of the first silicon carbide powder is 1~3 mm, and the particle diameter of the second silicon carbide powder is 0.08~ 1 mm; the particle size of the third silicon carbide powder is <0.08 mm; the mass ratio of the first silicon carbide powder, the second silicon carbide powder, and the third silicon carbide powder is 1:2.6:1.3. The particle size of graphite powder is 0.05~1mm. The particle size of metal silicon powder is 0.05~1 mm.

[0055] The preparation method of the silicon carbide hot-melt repair paste is as follows:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com