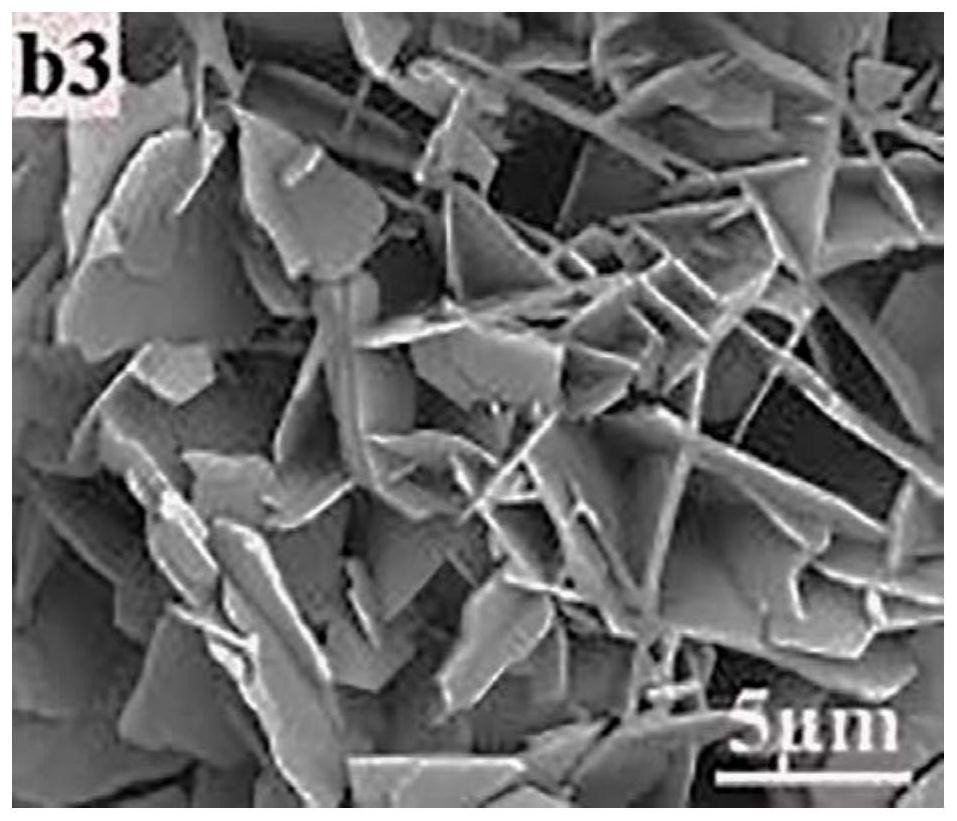

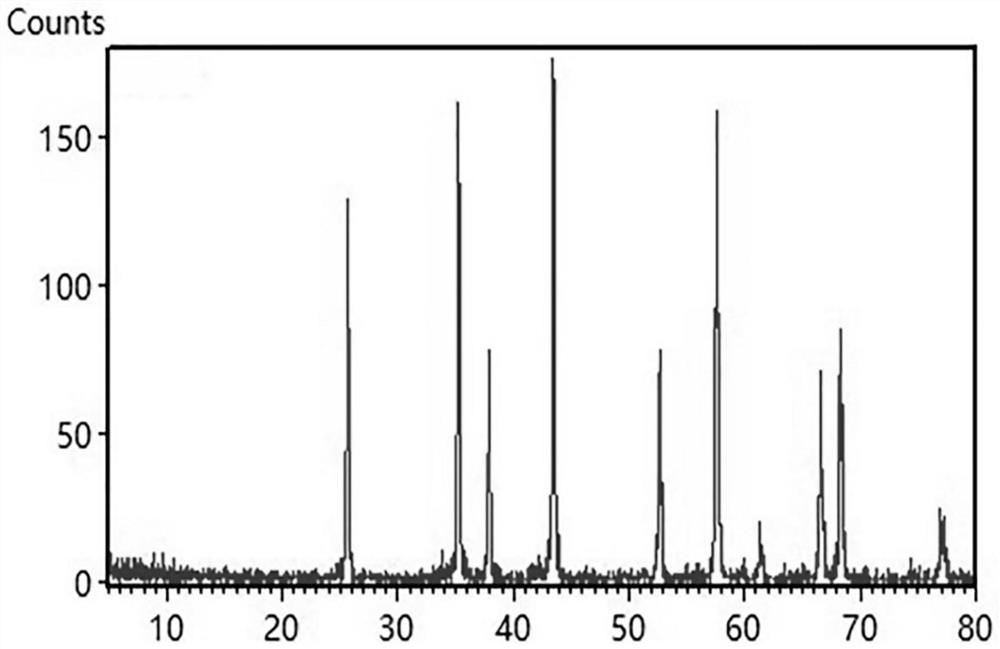

Method for preparing flaky aluminum oxide with high radius-thickness ratio by taking lotus root as template

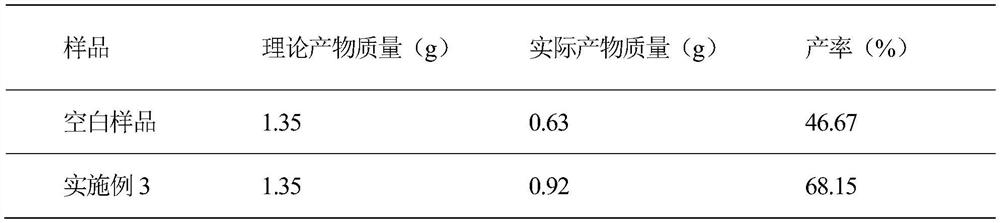

A flake-shaped alumina and high-diameter technology, applied in the field of materials, can solve the problems of being limited to the laboratory stage, failing to further popularize and promote production, and hindering the rapid development of the micro-nano-scale alumina fine raw material industry. Effects of increasing precipitation width, improving reaction efficiency, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Take 7.0g of malonylurea and 5.2g of polyaluminum chloride sol and add them to 40mL of dilute hydrochloric acid solution with a concentration of 1.2mol / L, heat and stir until the white polymer is completely dissolved to obtain solution A;

[0035]Step 2: Take 10g of fresh lotus root and place it in a far-infrared drying oven to dehydrate at 180°C for 36 hours, then cut it into blocks whose growth, width, and height are 4mm, 4mm, and 4mm respectively, and use a concentration of 0.3mol for the obtained blocks / L dilute nitric acid solution and absolute ethanol were washed 3 times in sequence, and then the washed strips were immersed in a glucose solution with a concentration of 2.2mol / L for 12 hours, and the product was collected to obtain the lotus root precursor B;

[0036] Step 3: first gradually add 40 mL of melamine solution with a concentration of 1.5 mol / L to solution A, then add a solution of dilute sodium hydroxide with a concentration of 0.4 mol / L to the ...

Embodiment 2

[0041] Step 1: Add 7.5g of malonylurea and 6g of polyaluminum chloride sol to 5mL of dilute hydrochloric acid solution with a concentration of 1.5mol / L, heat and stir until the white polymer is completely dissolved to obtain solution A;

[0042] Step 2: Take 15g of fresh lotus root and place it in a far-infrared drying oven for dehydration at 220°C for 34 hours, then cut it into blocks whose growth, width, and height are 5mm, 5mm, and 5mm respectively, and use a concentration of 0.4mol for the obtained blocks. / L dilute nitric acid solution and absolute ethanol were washed 5 times in sequence, and then the strips after washing were immersed in a glucose solution with a concentration of 3.0mol / L for filling treatment for 11 hours, and the product was collected to obtain lotus root precursor B;

[0043] Step 3: first gradually add 50 mL of melamine solution with a concentration of 1.2 mol / L to solution A, then add a dilute sodium hydroxide solution with a concentration of 0.6 mol...

Embodiment 3

[0048] Step 1: Add 8.0 g of malonylurea and 7.2 g of polyaluminum chloride sol to 60 mL of dilute hydrochloric acid solution with a concentration of 1.8 mol / L, heat and stir until the white polymer is completely dissolved to obtain solution A;

[0049] Step 2: Take 20g of fresh lotus root and place it in a far-infrared drying oven for dehydration at 280°C for 32 hours, then cut it into blocks with a length, width, and height of 6mm, 6mm, and 6mm, respectively, and use a concentration of 0.6mol for the obtained blocks. / L dilute nitric acid solution and absolute ethanol were washed 6 times in sequence, and then the washed strips were immersed in a glucose solution with a concentration of 3.2mol / L for 10 hours, and the product was collected to obtain the lotus root precursor B;

[0050] Step 3: first gradually add 60 mL of melamine solution with a concentration of 0.8 mol / L to the solution A, then add a diluted sodium hydroxide solution with a concentration of 0.8 mol / L to the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com