anti-overflow device

An anti-overflow, air-tight cabin technology, applied in deicing devices, transportation and packaging, aircraft parts, etc., can solve the problems of unsatisfactory anti-icing effect and large area to be controlled, so as to improve the anti-freezing effect and avoid recrystallization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description provides many different embodiments, or examples, for implementing various features of the invention. The elements and arrangements described in the following specific examples are only used to express the present invention in a concise manner, and are only used as examples rather than limiting the present invention.

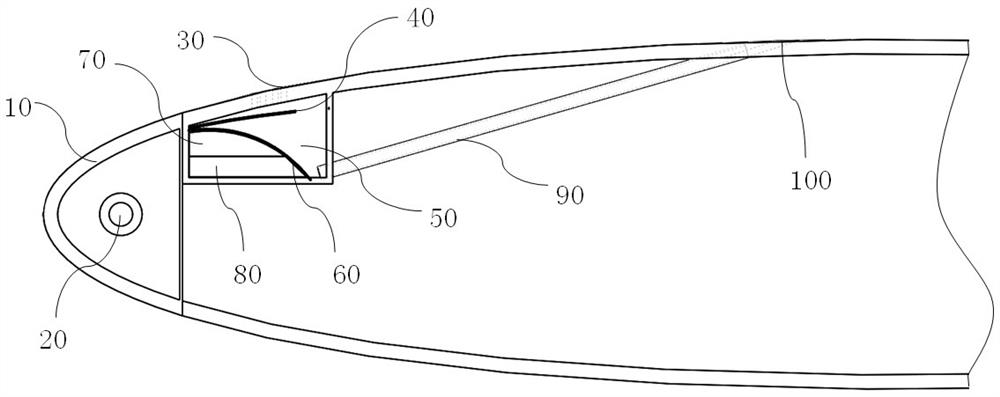

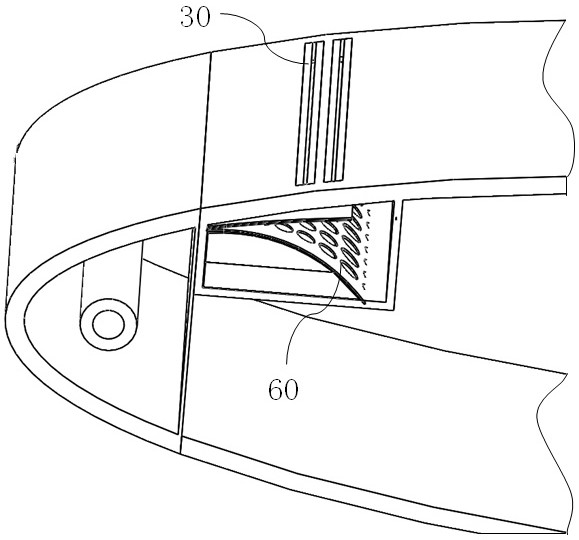

[0032] An anti-overflow device such as figure 1 As shown, it includes a slit 30 arranged on the windward side of the wing, at least one airtight chamber 50, an exhaust pipe 90 and an injection port 100; the airtight chamber 50 is arranged below the slit 30; one end of the exhaust pipe 90 It extends into the airtight chamber 50, and the other end is connected to the ejection port 100; the ejection port 100 is set on the suction peak or the high wind speed surface of the area where there is no direct collection of liquid water on the aerodynamic surface.

[0033] The size of the flow direction of the slit 30 (that is, the width of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com