Tyre

A technology for tires and treads, which is applied to tire parts, tire treads/tread patterns, vehicle components, etc., and can solve problems such as inability to fully exert the wiping effect, low ground pressure, and inability to fully improve braking performance. Achieve the effects of improving the wiping effect, increasing the ground pressure, and reducing the contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

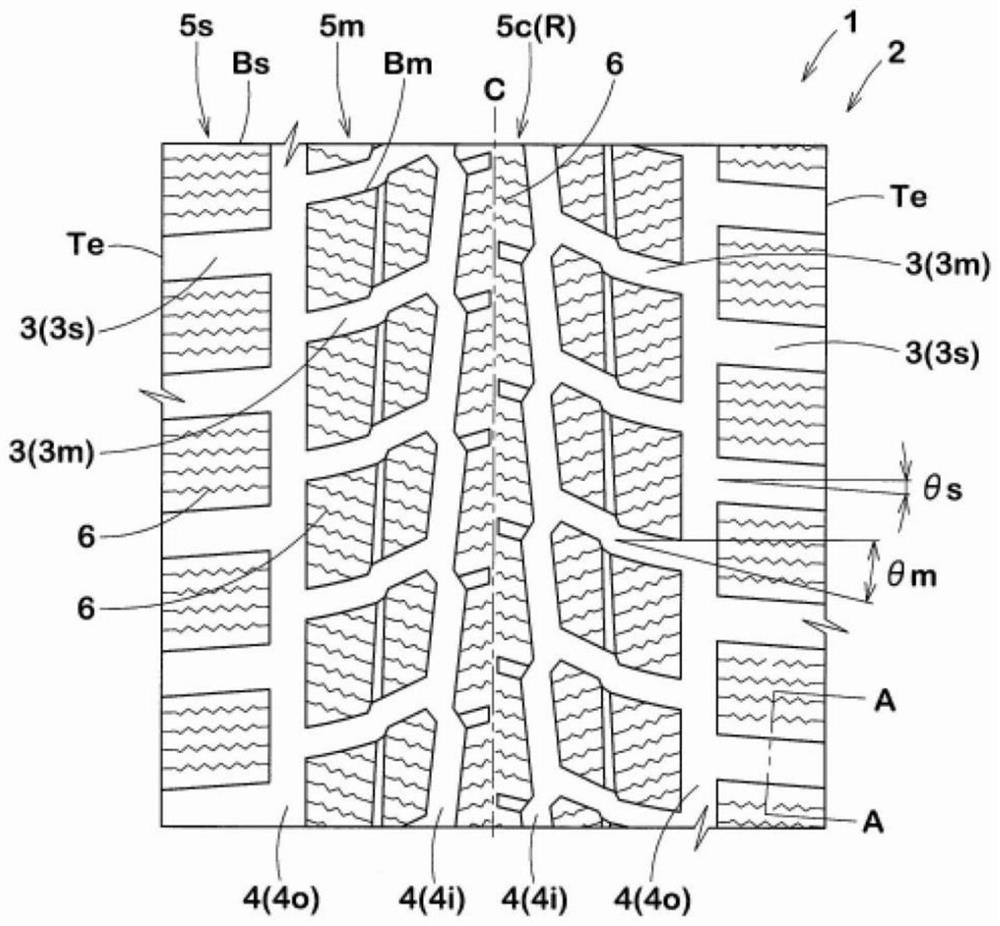

[0081] Prototype based on the specifications in Table 1 to figure 1 A studless tire of size 195 / 65R15 with the tread pattern shown as the basic pattern was tested for braking performance on icy roads when it was new and when it was 50% worn.

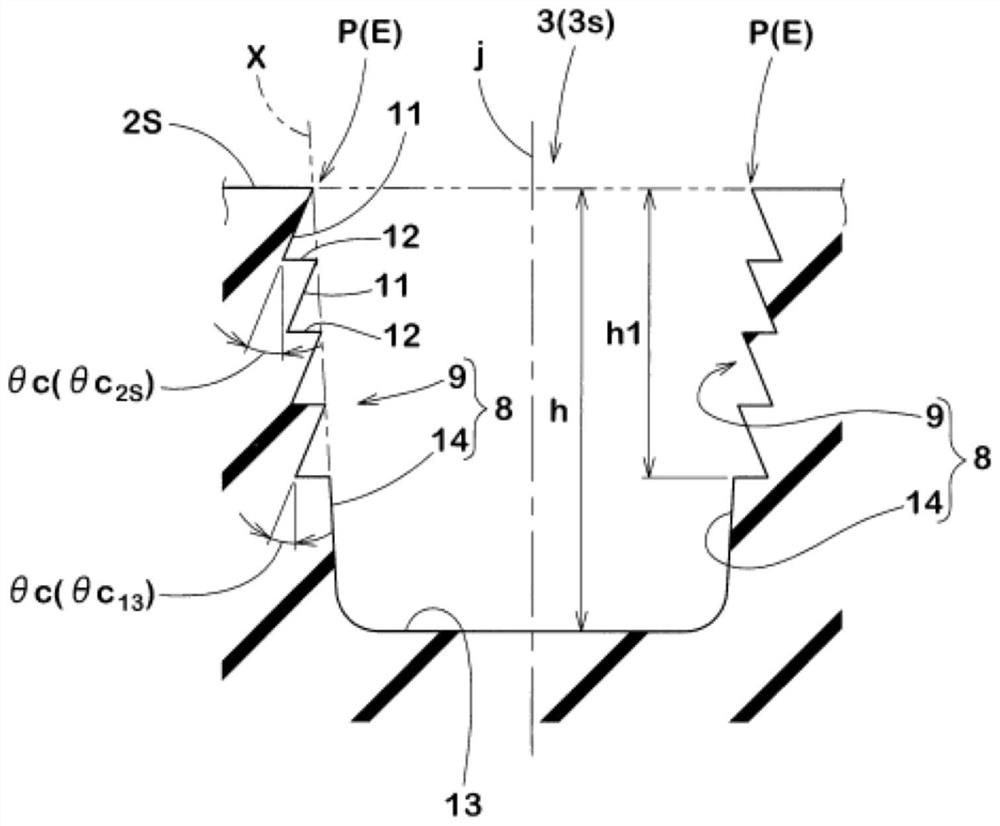

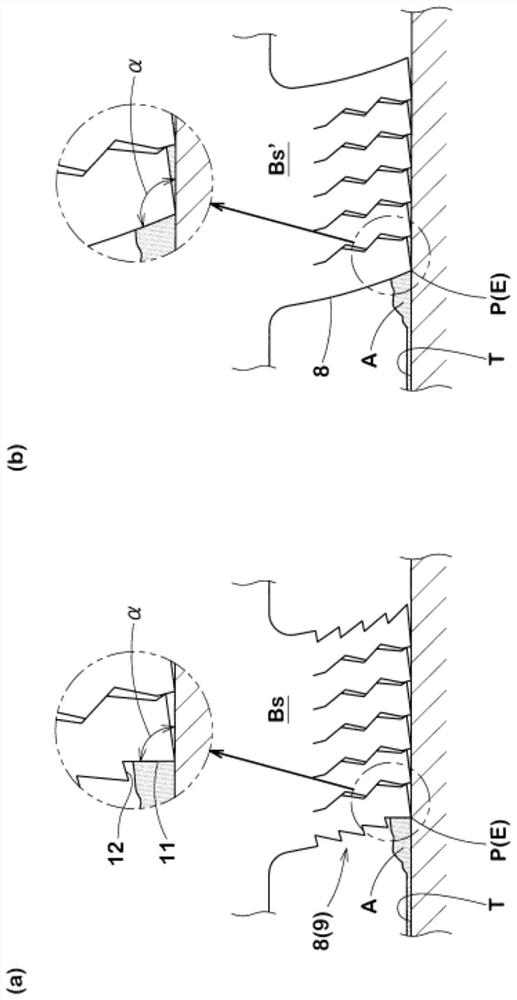

[0082] In Comparative Example 1, the wall surface of the lateral groove was formed with a slope inclined in a direction in which the groove width decreases as it goes toward the bottom of the groove. The angle of the wall with respect to the normal to the tread surface is 10 degrees. In Comparative Example 2, the wall surfaces of the lateral grooves were formed with slopes inclined in such a direction that the groove width increases toward the bottom of the groove. The angle of the wall with respect to the normal to the tread surface is 7 degrees. In the embodiment, serrations are formed on the wall surfaces of the middle lateral groove and the shoulder lateral groove. Furthermore, in Example 4, the angle θc becomes larger as the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com