Three-dimensional laser head for CO2 nonmetal laser cutting

A laser cutting and three-dimensional laser technology, applied in welding/cutting auxiliary equipment, welding/welding/cutting items, laser welding equipment, etc., can solve the problems that the laser head cannot meet the working requirements, and it is difficult to meet the processing requirements of composite material components, etc. Achieve the effect of expanding the range of processing capacity, reducing the weight of the mechanism, and improving the transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further explained below through specific embodiments.

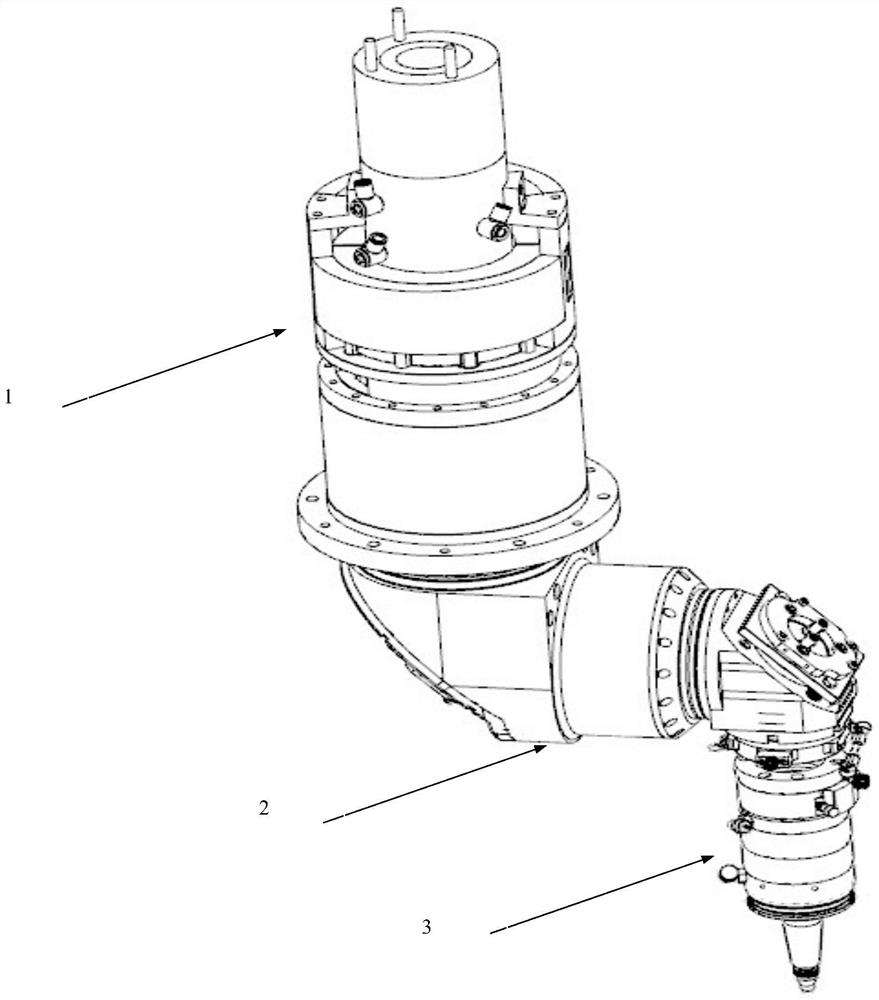

[0026] Referring to the accompanying drawings, the present invention provides a CO 2 The three-dimensional laser head for non-metallic laser cutting is characterized in that it includes a C-axis rotation assembly 1, a B-axis swing assembly 2 and a laser head 3, the B-axis swing assembly is installed on the shaft of the C-axis rotation assembly, and the laser head 3 is installed on the swing shaft of the B-axis swing assembly 2.

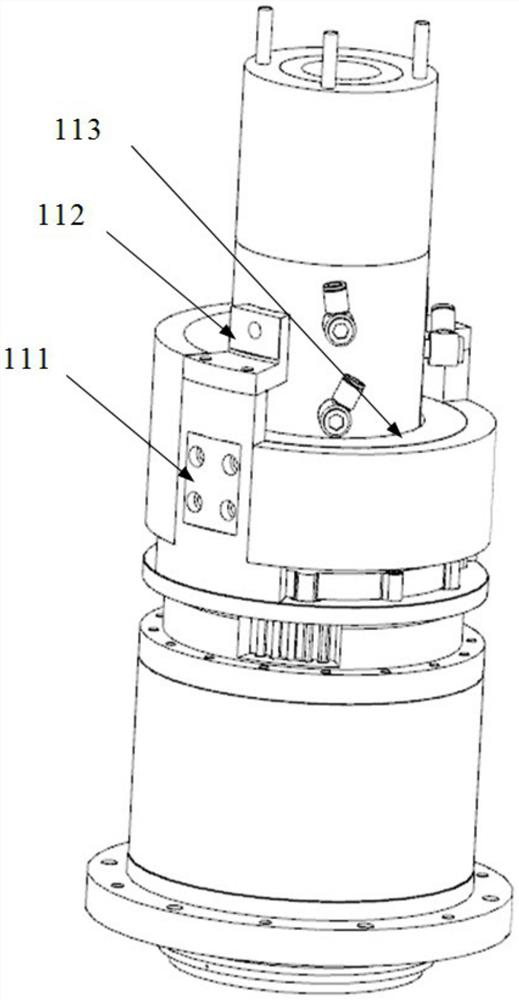

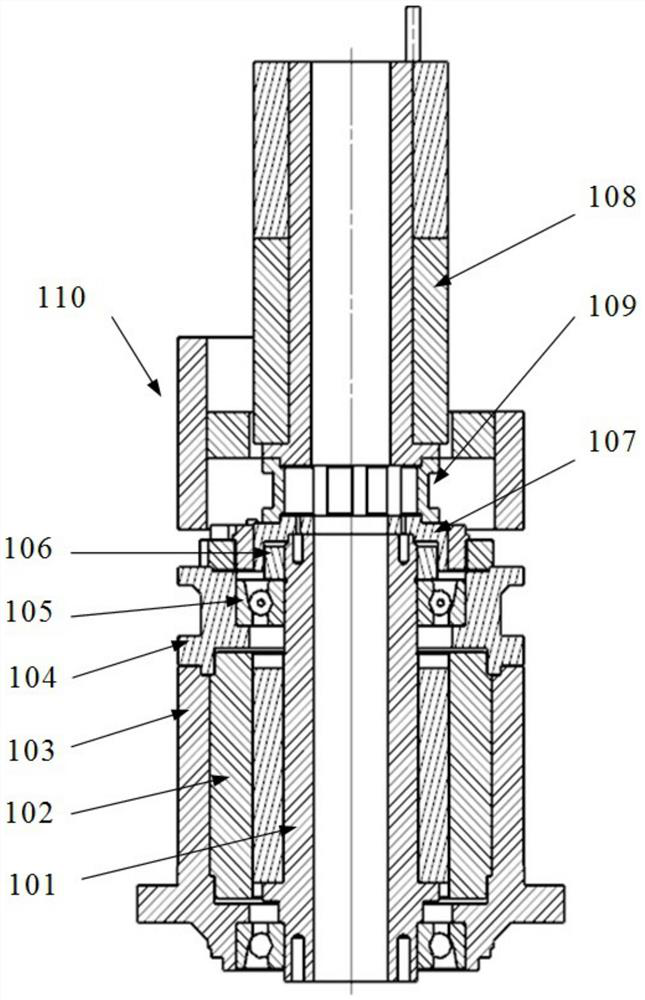

[0027] The C-axis rotating assembly 1 includes a rotating shaft 101, a C-axis motor 102, a C-axis encoder 107, and a gas-electric-hydraulic conductive slip ring 108; the rotor of the C-axis motor 102 is set on the rotating shaft 101 through screws, and the stator is set on the outer frame of the C-axis motor The inner side of 103; the outer side of the C-axis motor frame 103 is provided with a connecting flange matching the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com