Clamp device used for correcting perpendicularity of wire electrode and medium-speed wire cutting machine

A technology for calibrating electrodes and fixture devices, applied in accessories, manufacturing tools, electric processing equipment, etc., can solve the problems of extensive adjustment methods, low degree of refinement, and low product accuracy, and achieve refined adjustment operations and improved processing accuracy. , The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

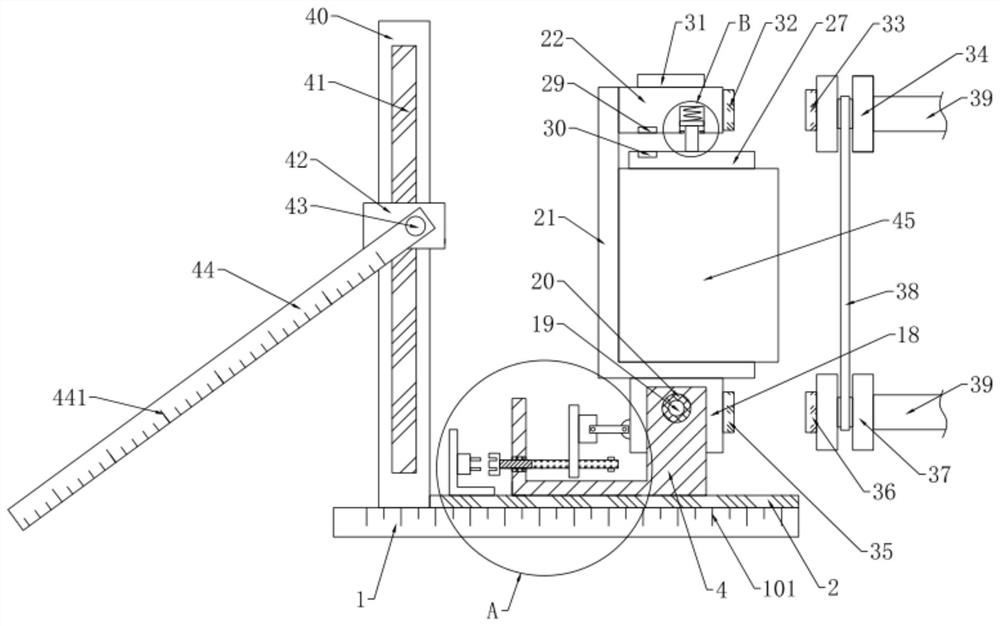

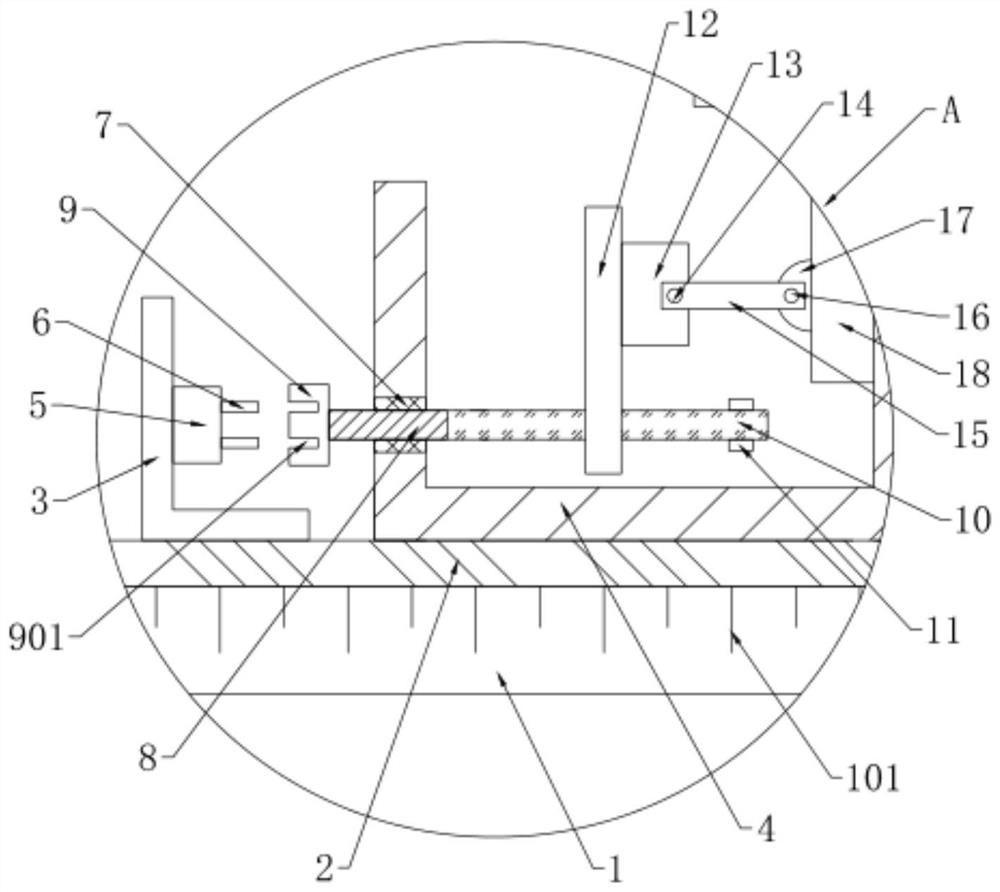

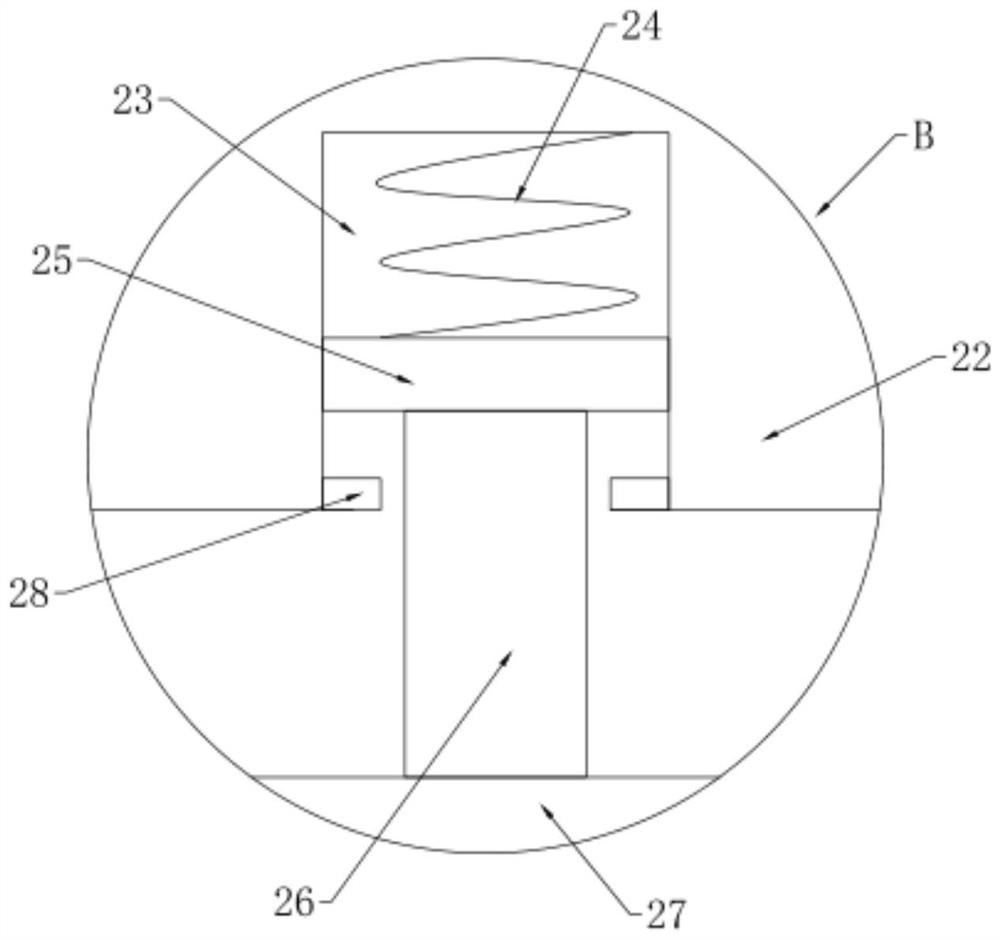

[0029] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0030] A fixture device for correcting the verticality of electrode wires, comprising:

[0031] Base plate 1, slide rail 2 is fixedly arranged on base plate 1, L-shaped slide plate 3 and U-shaped slide plate 4 are movable on slide rail 2, L-shaped slide plate 3 and U-shaped slide plate 4 can move on slide rail 2, L-shaped slide plate 3 A rotary motor 5 is fixedly installed on the side close to the U-shaped skateboard 4, the output end of the rotary motor 5 is fixedly provided with an insertion rod 6, and a first bearing 7 is embedded in the side wall of the U-shaped skateboard 4 close to the L-shaped skateboard 3 , the first bearing 7 is hingedly provided with a rotating rod 8, the rotating rod 8 can rotate, the first bearing 7 plays the role of movable support, the side of the rotating rod 8 close to the insertion rod 6 is fixedly provided with a handle 9, and the handle 9 corresponds t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com