Replaceable foam concrete hanging plate protection pipe gallery internal gas explosion device

A technology of foam concrete and protective pipes, which is applied in fire protection, water conservancy projects, artificial islands, etc., can solve problems such as the anti-explosion problem of the gas tank in the pipe gallery, and achieve the effects of good fire resistance, simple manufacture, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

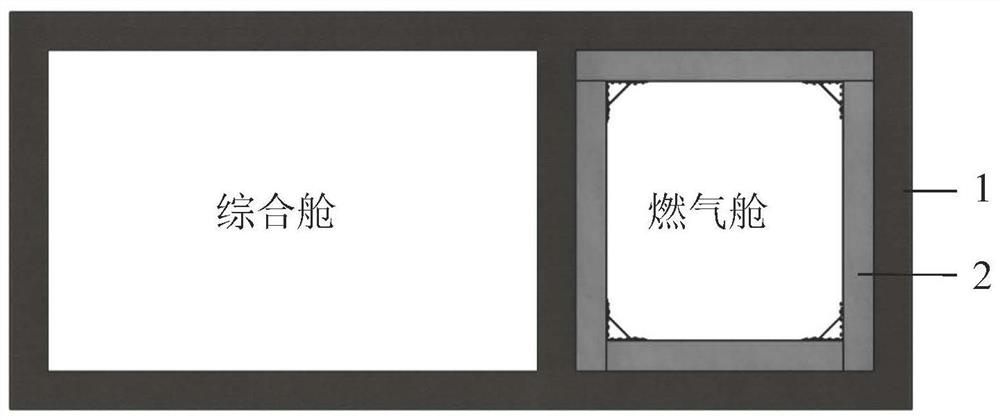

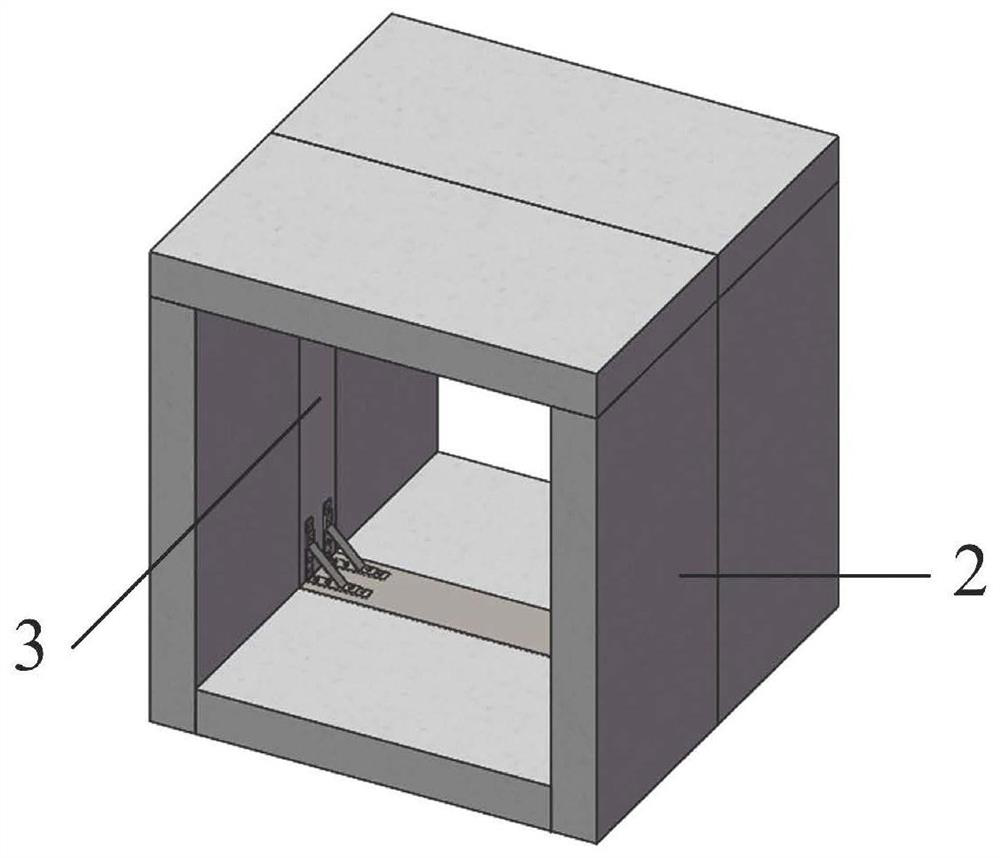

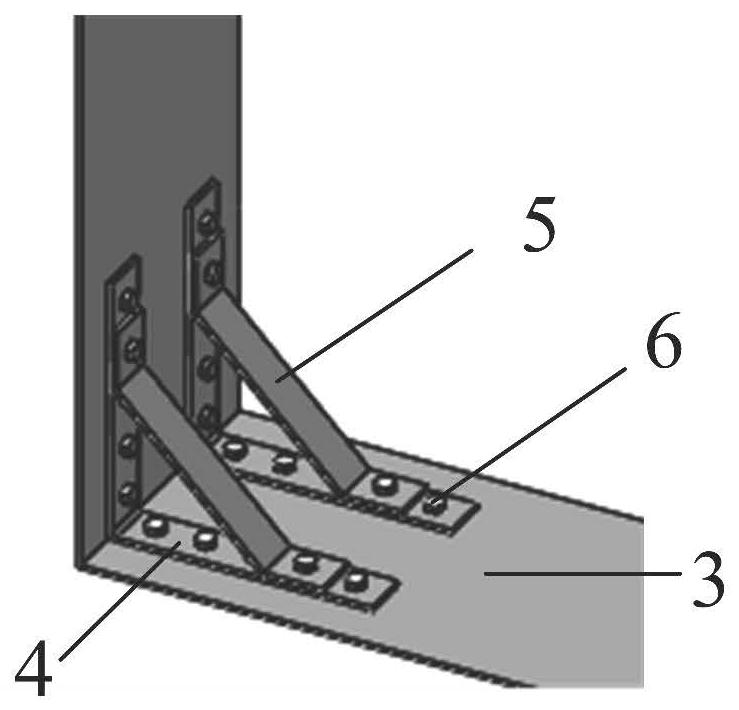

[0024] Such as figure 1 As shown, the present invention is a gas explosion protection device applied to the existing pipe gallery. The device includes a foam concrete hanging board 2, a steel plate 3, an angle steel 4, a brace 5 and a bolt 6. The whole device is spliced by four foam concrete hanging panels, and then the spliced foam concrete hanging panels are pasted on the inner surface of the gas tank of the pipe gallery to form a closed loop, and then the foam The position of the concrete siding is fixed. After the gas explosion, the explosion load is first transmitted to the surrounding foam concrete slabs. After the foam concrete slabs are compressed and destroyed to absorb a certain amount of energy, the explosion load is transmitted to the pipe gallery structure, which is equivalent to reducing the load inciden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com