A catalyst and direct conversion of synthesis gas to produce c 2 and c 3 olefin method

A catalyst and synthesis gas technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, molecular sieve catalysts, etc., can solve the problem of low selectivity between ethylene and propylene, and achieve high selectivity, high product yield and selectivity, The effect of activation conversion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

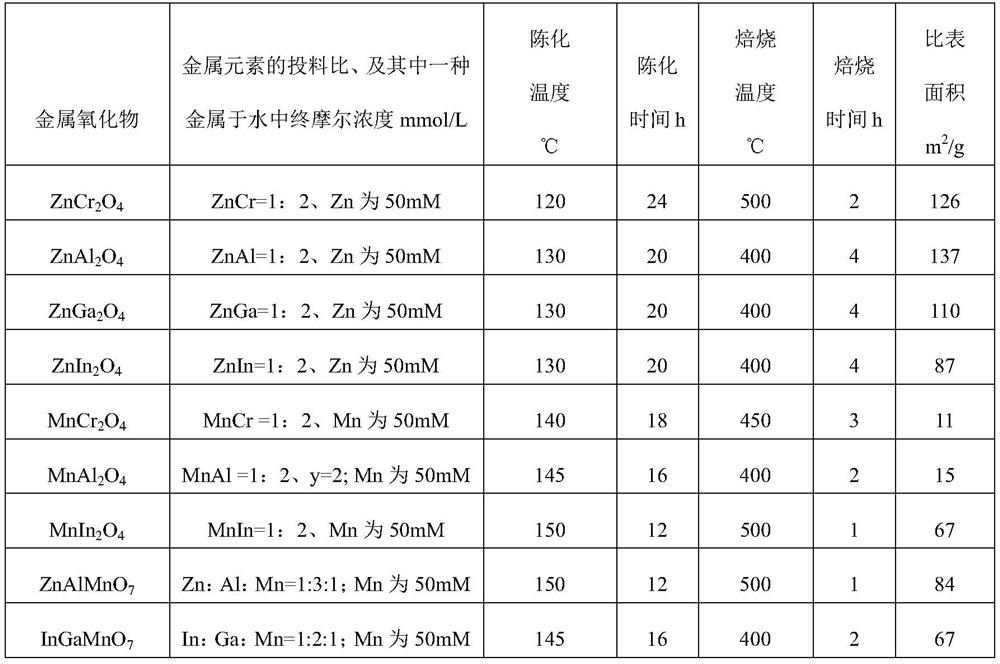

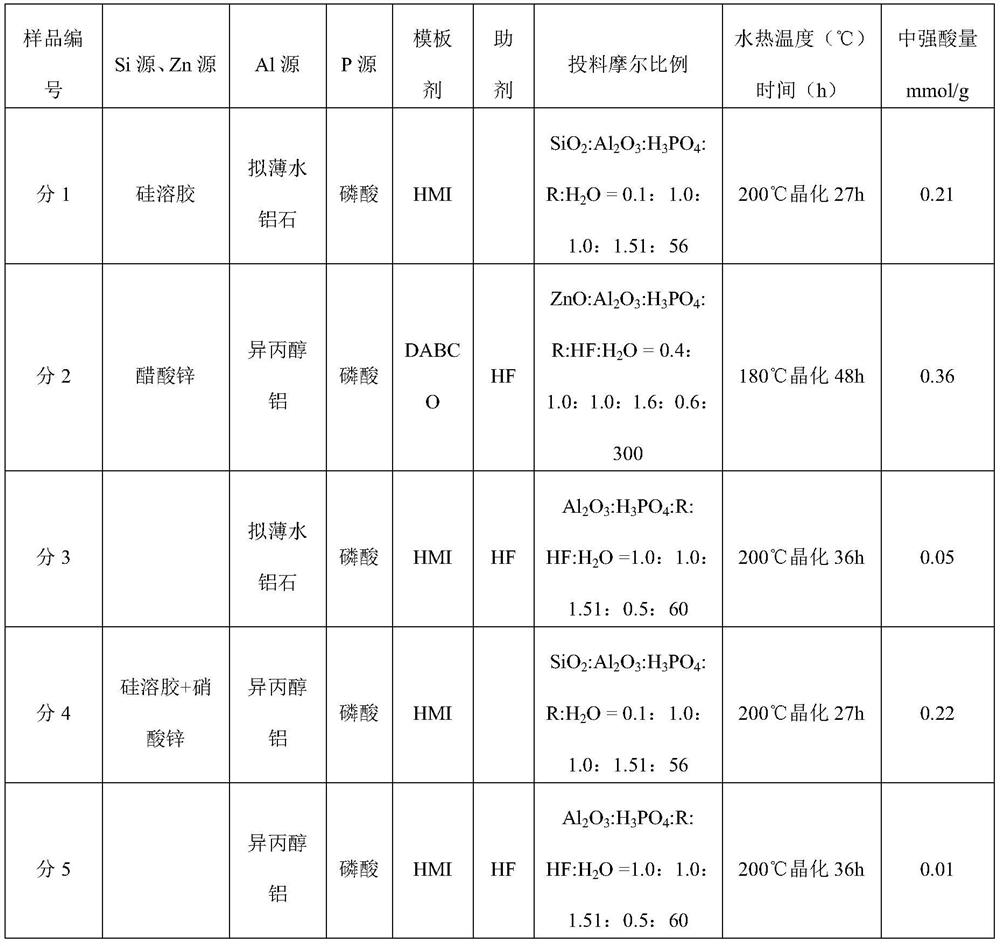

[0032] 1. Preparation of Catalyst Component I

[0033] (1) Synthesis of ZnO materials with high specific surface area by precipitation method:

[0034] (1) Weigh 3 parts, 0.446g (1.5mmol) Zn(NO 3 ) 2 ·6H 2 O in 3 containers, then weigh 0.300g (7.5mmol), 0.480g (12mmol), 0.720g (18mmol) NaOH and add them to the above 3 containers in turn, then add 30ml of deionized water to each of the 3 containers In the container, stir at 70°C for more than 0.5h to make the solution evenly mixed, and cool naturally to room temperature. The reaction solution was centrifuged to collect the precipitate after centrifugation, and washed twice with deionized water to obtain the ZnO metal oxide precursor;

[0035] (2) Roasting: After the above-mentioned obtained product is dried in the air, it is calcined in the atmosphere to obtain a ZnO material with a high specific surface area. The atmosphere is inert gas, reducing gas or oxidizing gas; the inert gas is N 2 One or more of , He and Ar; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com