Composite tissue production equipment and production method

A technology for producing equipment and paper towels, applied in household appliances, machining/deformation, etc., can solve the problems of low actual adhesion of embossing, inconvenience for users, no adhesion, etc., to avoid clogging, improve production efficiency and adhesion. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

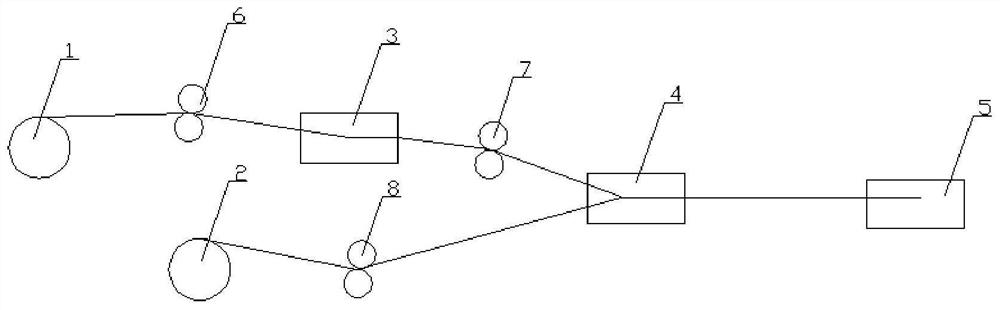

[0019] Such as figure 1 Shown, a kind of production equipment of compound paper towel comprises the first unwinding device 1, the second unwinding device 2, the hot melt adhesive coating device 3, the paper towel pressing device 4 and the paper towel embossing device 5, the first A first paper guide roller 6 is arranged between the unwinding device 1 and the hot-melt adhesive coating device 3, and a second paper guide roller 7 is arranged between the hot-melt adhesive coating device 3 and the paper towel pressing device 4, so that A third paper guide roller 8 is provided between the second unwinding device 2 and the paper towel pressing device 4; the hot melt adhesive coating device 3 includes a hot melt adhesive storage tank, a dotted anilox roller and an au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com