Assembly skill direct generation method based on virtual assembly environment

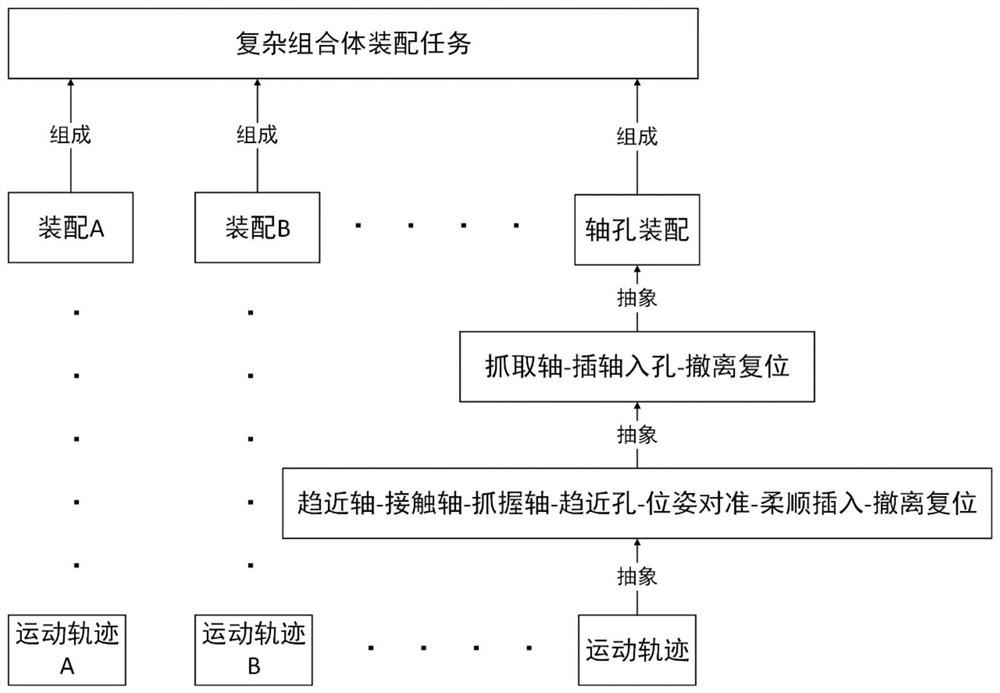

A technology of virtual assembly and virtual environment, applied in the field of operation skills learning in artificial intelligence, which can solve the problems of not using direct operation data, many methods, and operation skills cannot be transferred.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

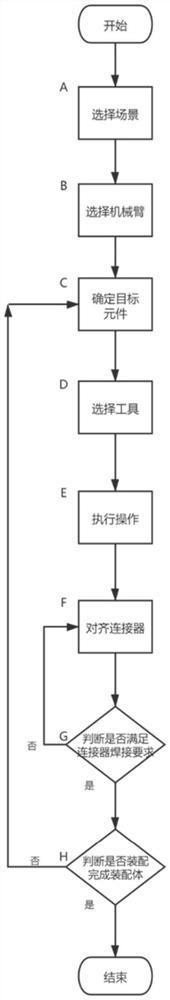

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

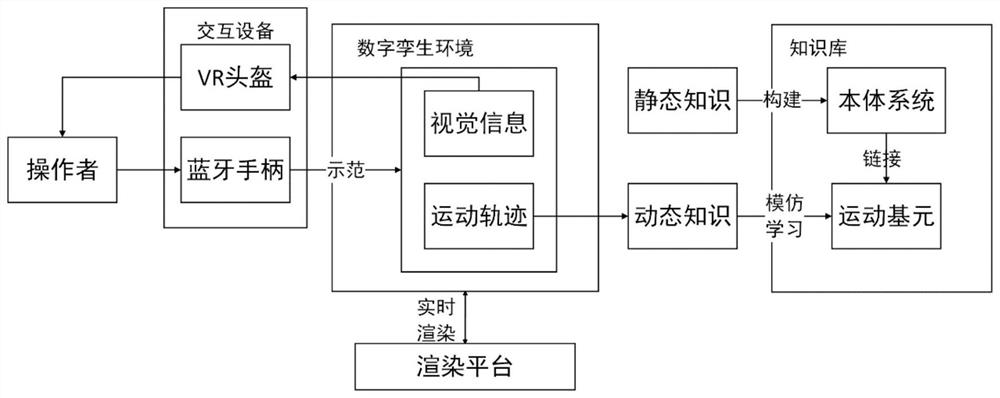

[0038] The method for directly generating assembly skills based on the virtual assembly environment of the present invention, such as figure 2 As shown, it includes a set of VR equipment for human operators to interact with the virtual environment, a digital twin environment of a 3C assembly scene, and a knowledge base containing assembly operation knowledge.

[0039] The VR device is Oculus Quest 2, which includes a VR helmet and a pair of Bluetooth handles; after the operator runs the system, the operator wears the VR helmet and can see the assembly process table in the virtual environment from a first-person perspective, while the Bluetooth handle Responsible for manipulating the robotic arm in the virtual scene to perform corresponding actions.

[0040] The generation method of the digital twin environment of the 3C assembly scene is as follows:

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com