Method for determining mechanical constitutive parameters of nickel-series low-temperature steel containing film-shaped metastable austenite

A technology for parameter determination and austenite, which is applied in the field of determination of mechanical constitutive parameters of nickel-based low-temperature steels, can solve problems such as small size, difficult two-phase constitutive parameters, and continuous evolution of metastable austenite volume fraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

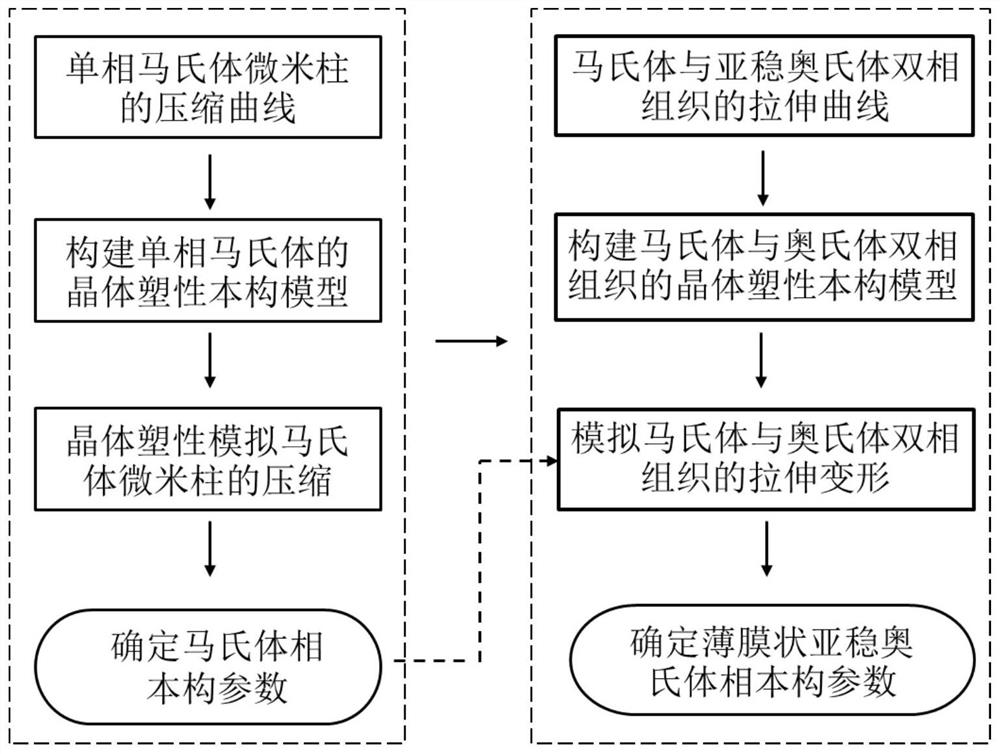

[0112] For the flow diagram of the method for determining the mechanical constitutive parameters of nickel-based low-temperature steel containing film-like metastable austenite (9Ni steel sample is used in this embodiment), refer to the attached figure 1 ,Specific steps are as follows:

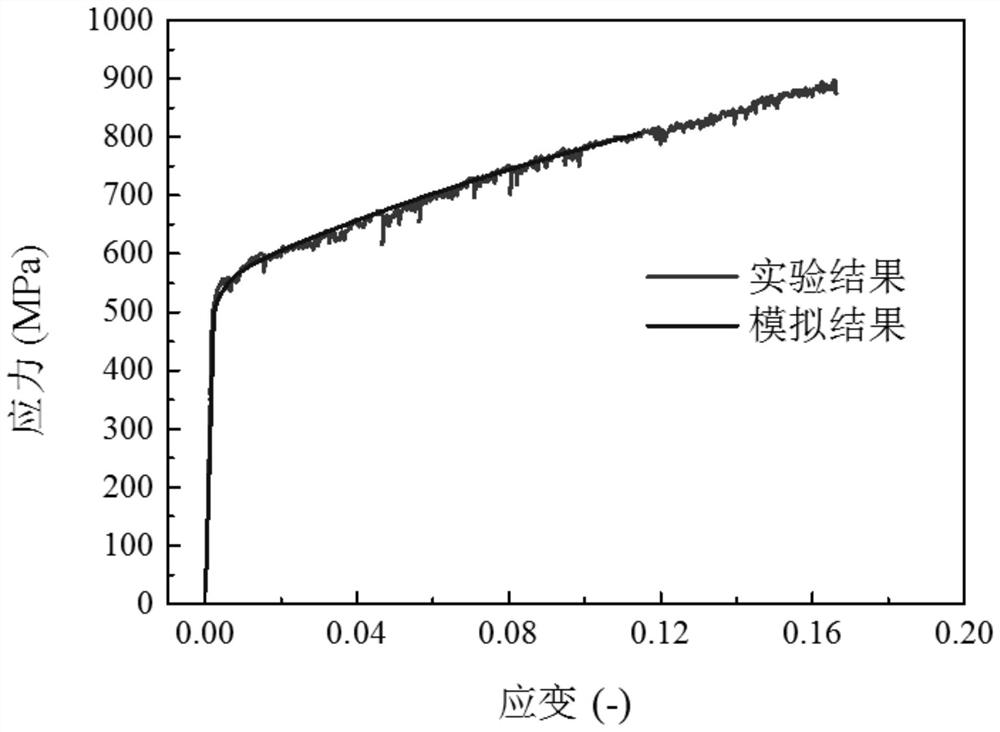

[0113] 1) Obtain the compressive stress-strain curve of single-phase martensitic microcolumns

[0114] 1.1) The 9Ni steel sample was kept at 900°C for 1 hour, then water-cooled and quenched, and then kept at 550°C for 30 hours;

[0115] 1.2) The volume fraction of metastable austenite measured by X-ray diffractometer method is 7.2%;

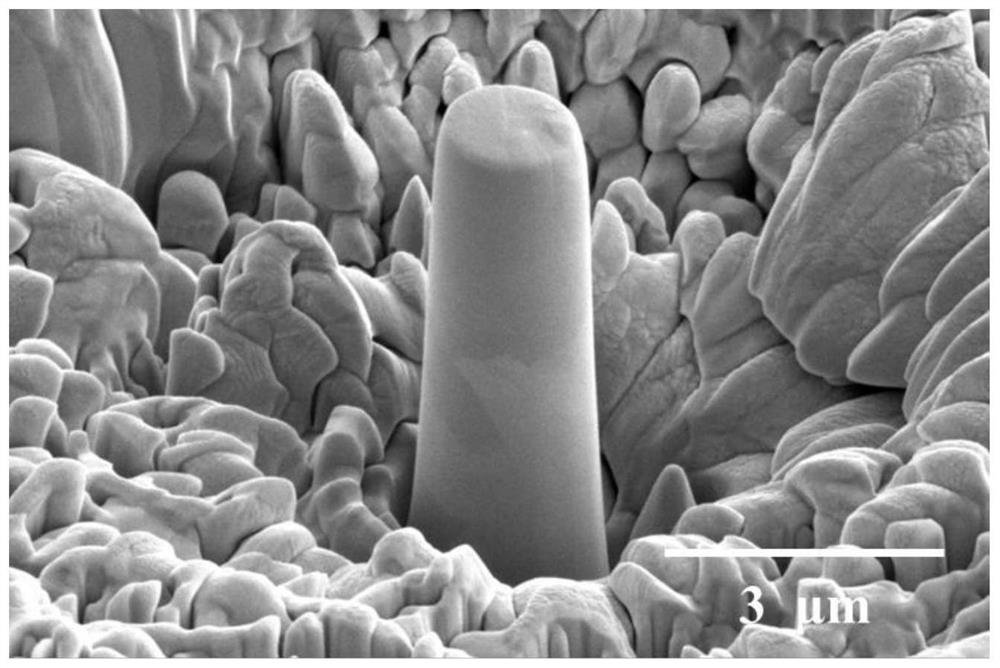

[0116] 1.3) Use the focused ion beam to process the sample after heat treatment to produce micron columns containing only single-phase martensite, and the diameter of the micron column is 1-2 μm, the height is 3-5 μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com