Temperature control system with ultrahigh temperature control precision

A temperature control system and precision technology, applied in the field of precision temperature control, can solve the problem that the temperature control system cannot achieve precise temperature control, and achieve the effect of improving the temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

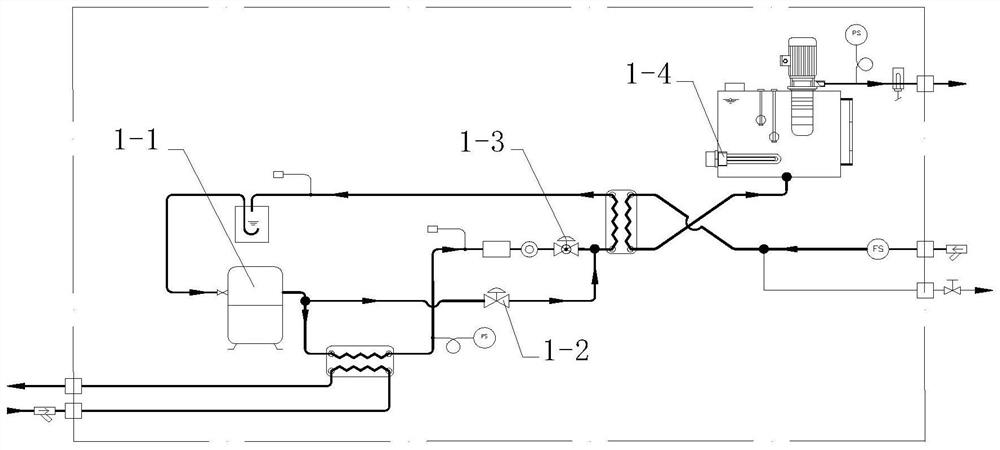

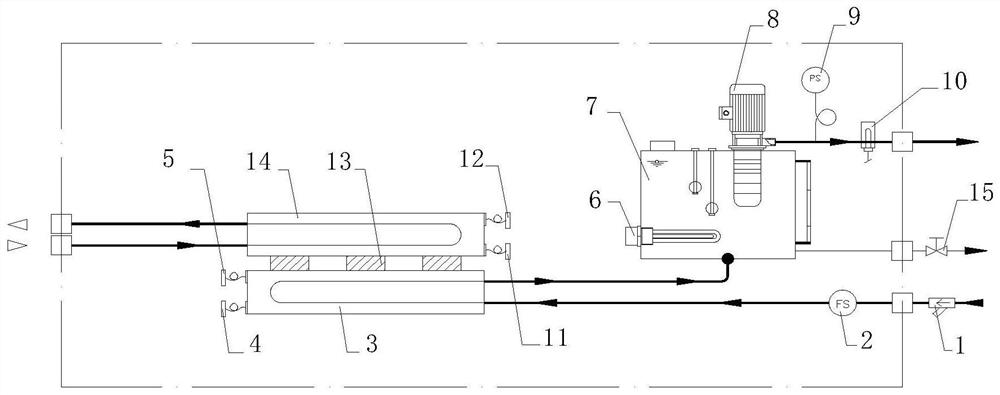

[0031] A temperature control system with ultra-high temperature control precision, including a microcomputer processor, a circulating fluid system and a plant cooling water system, the circulating fluid system includes a circulating fluid pipeline and a filter 1 sequentially installed in the circulating fluid pipeline , the second heat exchange cold plate 3, the water tank 7 and the circulating fluid temperature sensor 10, the circulating fluid pipeline is provided with the target circulating fluid that requires precise temperature control, the water tank 7 is equipped with a water pump 8 for the circulating flow of the target circulating fluid, and The water tank 7 is provided with a heating wire I6 whose output frequency is controlled by the microcomputer processor, and the circulating fluid temperature sensor 10 is used to collect the temperature signal of the target circulating fluid;

[0032] The plant cooling water system includes a plant water pipeline and a first heat e...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is that, as figure 2 As shown, a flow meter 2 is installed on the circulating liquid pipeline, and the flow meter 2 is arranged between the filter 1 and the second heat exchange cold plate 3 for monitoring the flow rate of the circulating fluid in the circulating liquid pipeline. When the value is lower than the target value, the cooling or heat generated by the semiconductor refrigeration sheet 13 cannot be taken away and is damaged. At this time, the temperature control system stops running with the cooperation of the microcomputer processor to realize the protection of the temperature control system.

Embodiment 3

[0039] The difference between this embodiment and embodiment 1 is that, as figure 2 As shown, the circulating fluid pipeline is equipped with a pressure sensor 9 for monitoring the pressure of the circulating fluid in the circulating fluid pipeline, and the pressure sensor 9 is arranged downstream of the water tank 7, and is used to measure the pressure of the circulating fluid and compare with the preset maximum Comparing the pressure value or the minimum pressure value, if it exceeds the upper or lower limit of the set value, cooperate with the microcomputer processor to realize the warning or stop the operation of the temperature control system to realize the protection of the temperature control system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com