Machining emulsified waste liquid reduction treatment system and treatment method thereof

A mechanical processing and treatment system technology, applied in chemical instruments and methods, heating water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as difficult treatment, aggravating the operating burden of enterprises, environmental impact, etc., to reduce pollution. Emissions and the effect of solving environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

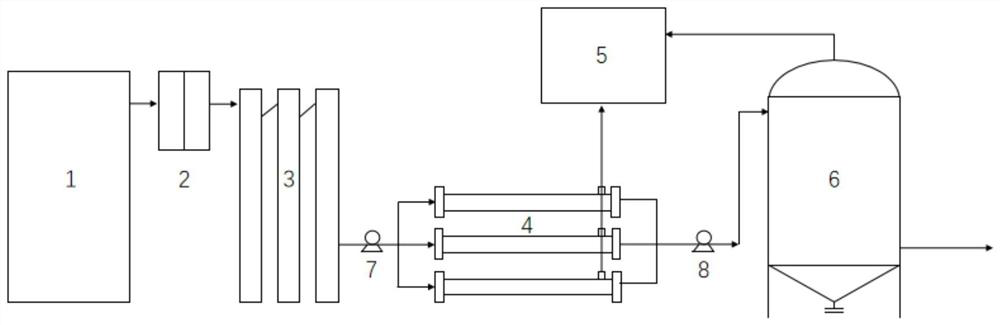

[0025] A mechanical processing emulsified waste liquid reduction treatment system, such as figure 1 As shown, it includes emulsification stock solution tank 1, filter 2, three-stage series advanced oxidation tank 3, reverse osmosis water treatment equipment 4, produced water tank 5, low-temperature evaporator 6, small centrifugal pump 1 7, and small centrifugal pump 2 8.

[0026] The filter 2 includes two activated carbon adsorption filter tanks connected in series. The outer material of the activated carbon adsorption filter tank is made of glass fiber reinforced plastic. A valve is arranged between the two activated carbon adsorption filter tanks. The first layer of activated car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com