A tension self-balancing multi-rope winding lifting system and method

A lifting system and self-balancing technology, which is applied to lifting equipment in mines, elevators, elevators in buildings, etc., can solve the problems of low load of multi-rope friction lifting, difficult arrangement of multi-rope winding lifting, and poor tension balance. Achieve the effect of simple and light structure, simple structure, and prevent contact interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] The tension self-balancing multi-rope winding lifting system of this embodiment includes,

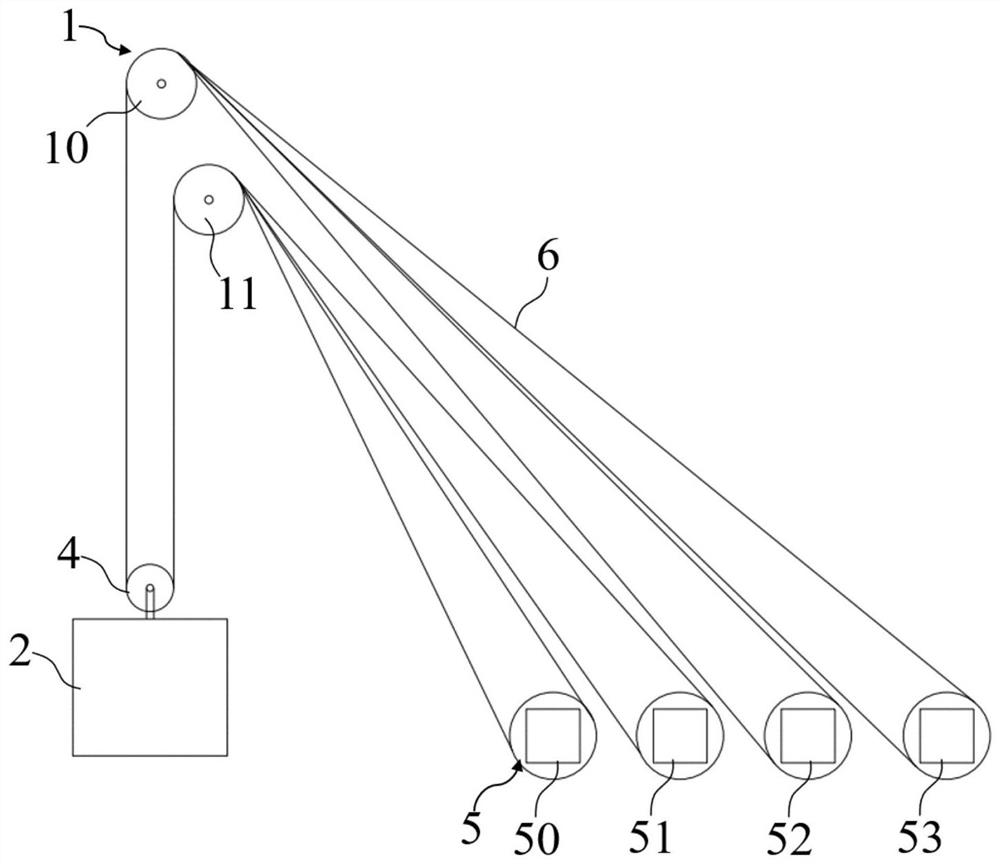

[0095] guide wheel train 1;

[0096] Lifting container one 2 and lifting container two 3 arranged below the guide wheel train 1;

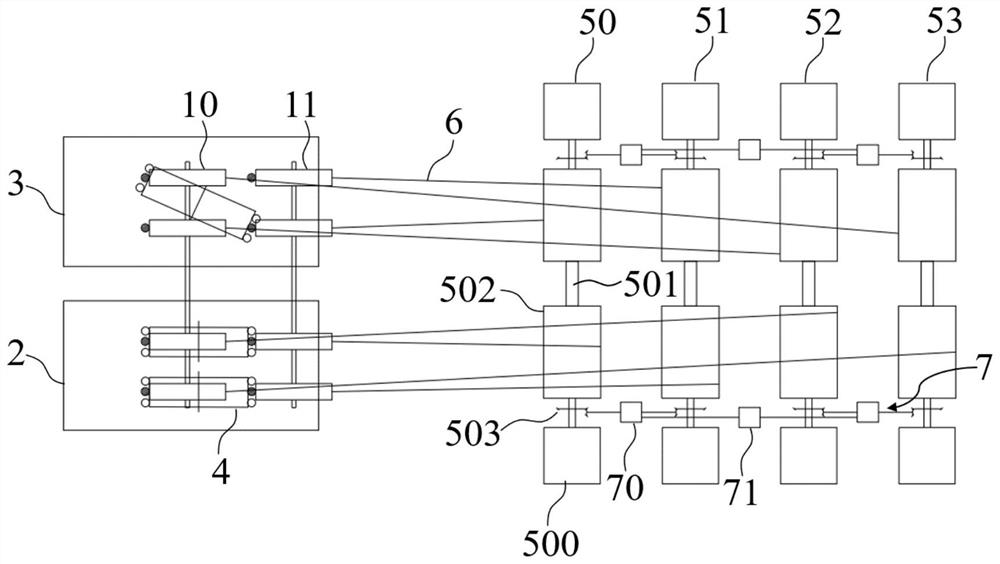

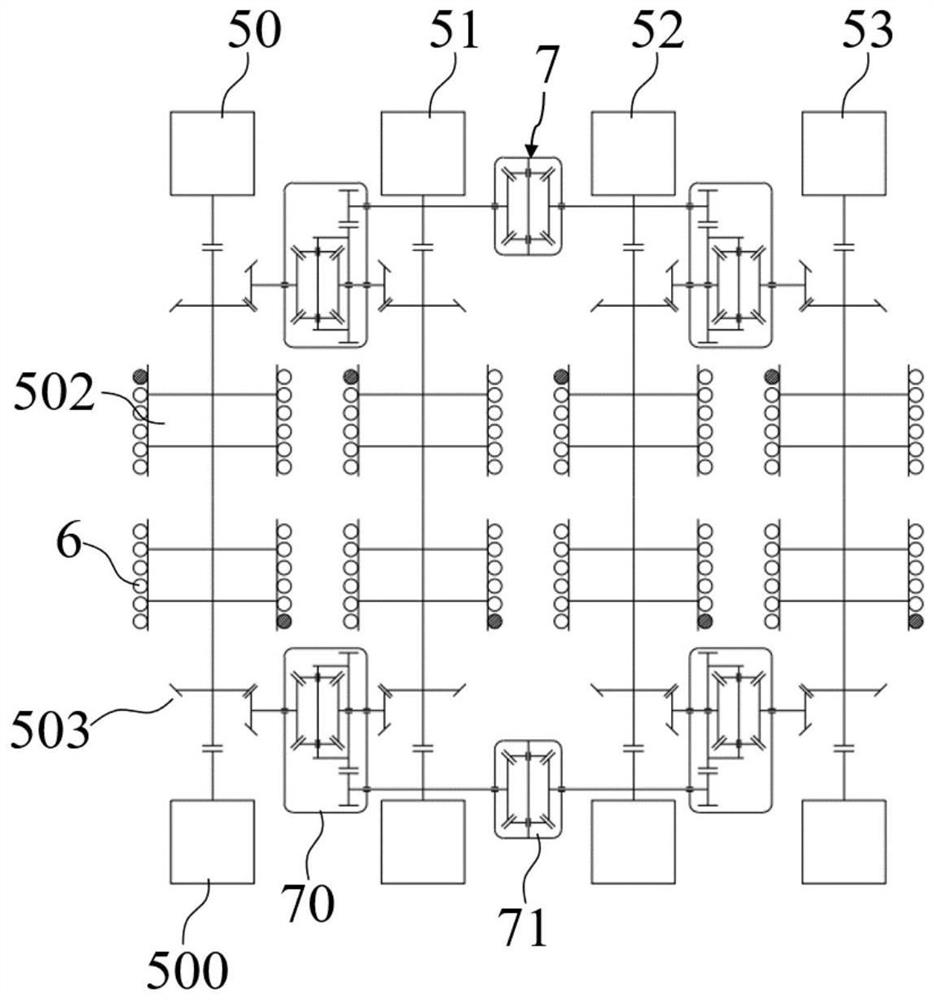

[0097] Drive unit 5, it is made up of drive unit one 50, drive unit two 51, drive unit three 52 and drive unit four 53 arranged in sequence, each drive unit structure is all the same, and mutually parallel arrangement; Each drive unit comprises drive motor 500, the main shaft 501 and the roller 502, the driving motor 500 provides the driving force for the rotation of the main shaft 501, and each main shaft 501 is socketed with two rollers 502;

[0098] Lifting rope group 6, one end of which is connected to the drum 502 in transmission, and the other end is connected to the top of lifting container 1 2 and lifting container 2 3 after bypassing the top of guide wheel system 1;

[0099] A transmission bevel gear 503 is sleeved on the main shaft 501 of ...

Embodiment 2

[0113] The tension self-balancing multi-rope winding lifting system of this embodiment is further improved on the basis of Embodiment 1. A primary tension equalization unit 70 is arranged between the drive unit one 50 and the drive unit two 51, and the drive unit three 52 and the drive unit A first-level tension equalization unit 70 is also arranged between unit four 53, and two first-level tension equalization units 70 are symmetrically arranged;

[0114] The primary tension equalization unit 70 also includes a large gear 709, which is rotatably sleeved on the second half shaft 704;

[0115] The tension equalization part 7 also includes a secondary tension equalization unit 71, which includes:

[0116] Shell two 710, which is a hollow structure, placed between the drive unit two 51 and the drive unit three 52;

[0117] There are two transmission mechanisms, symmetrically arranged on both sides of the housing two 710, each transmission mechanism includes a major shaft 711, a ...

Embodiment 3

[0125] The tension self-balancing multi-rope winding hoisting system of this embodiment is further improved on the basis of Embodiment 2. Drive unit 1 50, drive unit 2 51, drive unit 3 52 and drive unit 4 53 have their respective main shafts 501 from front to back The height position of each drive unit increases successively, and the main shafts 501 of each drive unit are all in the same plane.

[0126] Such as Figure 5 As shown, the main shafts 501 of the four driving units are in the same plane, and this plane forms an angle θ with the horizontal plane. Through the setting of this embodiment, on the one hand, it can effectively prevent the contact interference between the lifting ropes. On the other hand, this Compared with directly arranging the main shafts 501 on the horizontal plane, the arrangement can make the hoisting ropes on the rear row of drums 502 obtain a smaller chord length and reduce the amplitude of the hoisting ropes, thereby preventing the hoisting ropes f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com