Tensioning structure of chains for garlic harvesting equipment conveyor

A conveyor and chain technology is applied in the field of garlic harvesting equipment and the tension structure of the chain used for the garlic harvesting equipment conveyor, which can solve the problem that the garlic harvester has high pressure on the field, the thickness of the chain plate is not too large, and the technical solutions are endless. Reasonable and other issues to avoid bruising the garlic head, light weight, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

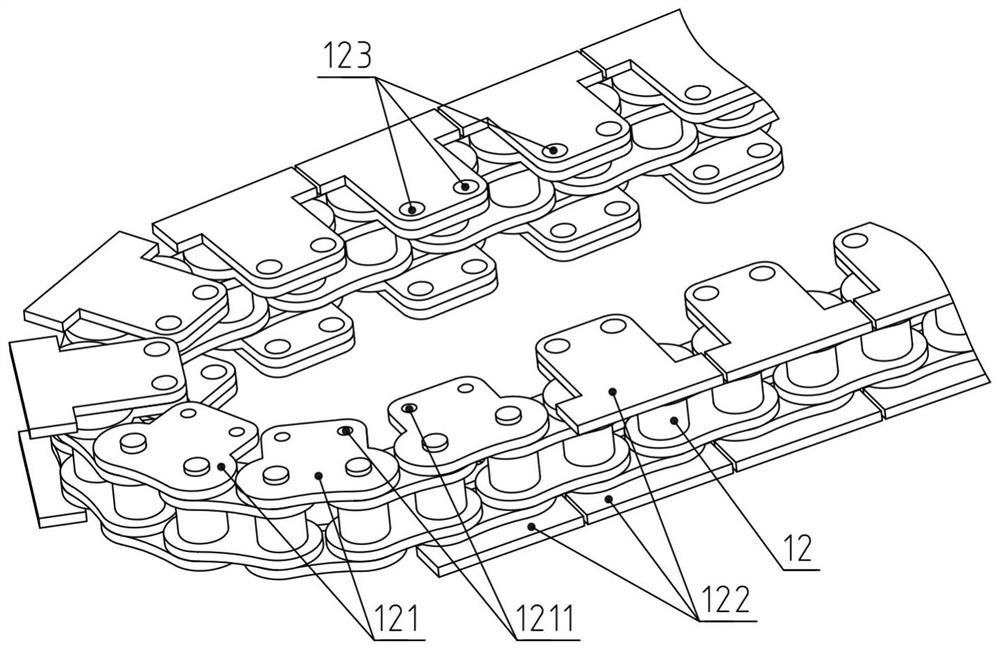

[0047] Example 1, such as Figure 1-4 Said:

[0048] A chain tensioning structure for a garlic harvesting equipment conveyor, comprising a conveyor frame 0; the conveyor frame 0 is connected to the garlic harvesting equipment conveyor;

[0049] Such as figure 1 As shown, embodiment 1 also includes a plurality of chain assembly pairs; a chain assembly pair includes a left chain assembly 1, a right chain assembly 2 and a plurality of tensioning sprocket assemblies 3;

[0050] A left chain assembly 1 includes a left drive sprocket 11, a closed-loop left chain 12, a left reversing sprocket 13, a left reversing sprocket shaft 14 and a left reversing wheel spring 15;

[0051] The shaft of the left drive sprocket 11 is connected with the conveyor frame 0 through a rotating pair, and the shaft of the left drive sprocket 11 is connected with the power input device; the left reversing sprocket 13 is in the front or left front of the left drive sprocket 11; The left reversing sprocke...

Embodiment 2

[0062] Example 2, such as Figure 5-8 Said:

[0063] A chain tensioning structure for a garlic harvesting equipment conveyor, comprising a conveyor frame 0; the conveyor frame 0 is connected to the garlic harvesting equipment conveyor;

[0064] like Figure 5 As shown, Embodiment 1 also includes a plurality of chain assembly pairs; a chain assembly pair includes a left chain assembly 1, a right chain assembly 2, one or more movable arc-shaped plate assemblies 5 and one or more fixed arc-shaped plates 6. The movable arc-shaped plate assembly 5 is arranged on the left side of the left chain 12, and the fixed arc-shaped plate 6 is arranged on the right side of the left side of the right chain 22, and the movable arc-shaped plate assembly 5 and the fixed arc-shaped plate 6 appear alternately;

[0065] The structure and installation method of the left chain assembly 1 and a right chain assembly 2 are the same as those in Embodiment 1, and will not be described again.

[0066] li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com