Kitchen appliance glass high-temperature printing device and technology

A printing device and glass technology, applied in the direction of printing devices, printing, printing machines, etc., can solve the problems of no detection and reminder of electrical appliances, affecting the use of electrical appliances, unsatisfactory thermal conductivity and compressive strength of high borosilicate glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

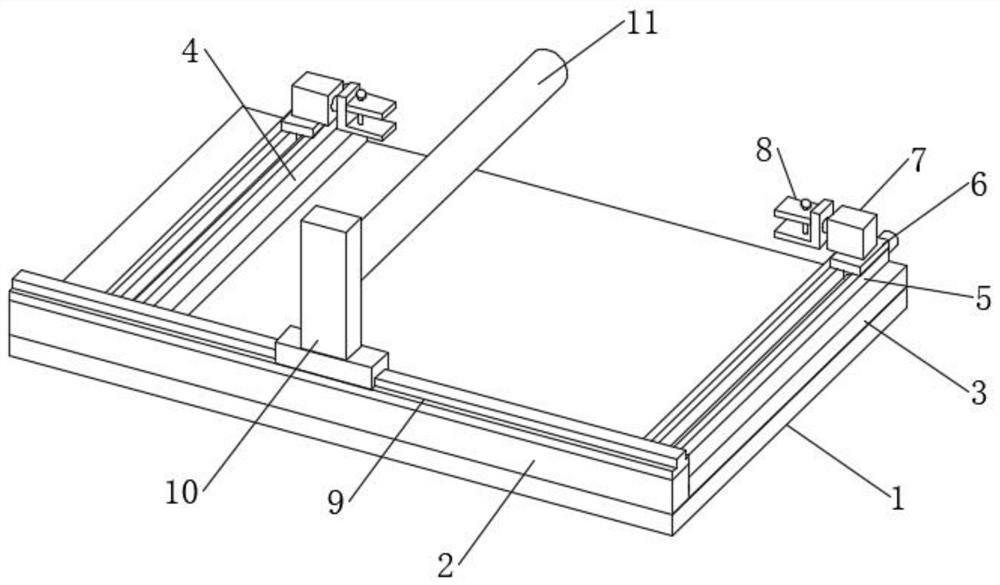

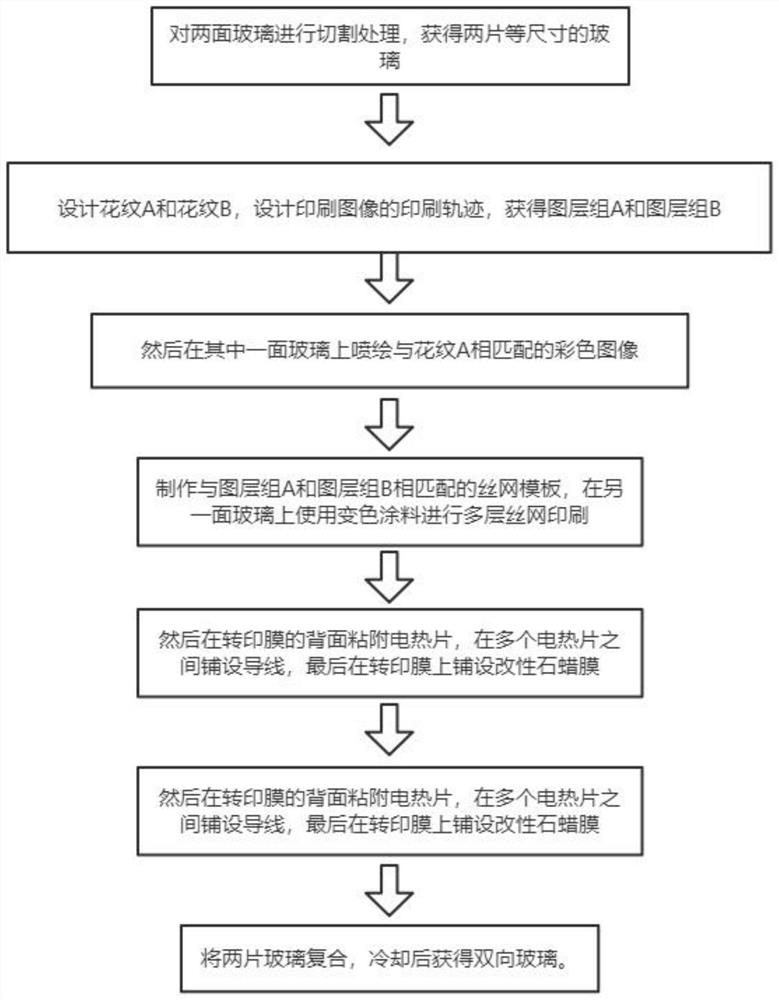

[0045] see Figure 1-3, a high-temperature printing device for kitchen electric glass and its technology, comprising a processing table 1, a longitudinal slide rail 2 is fixedly connected to the processing table 1, a fixed plate 3 is fixedly connected to one end of the longitudinal slide rail 2, and a sliding connection is made to the longitudinal slide rail 2 There is a movable plate 4, the fixed plate 3 and the movable plate 4 are fixedly connected with a transverse guide rail 5, the transverse guide rail 5 is slidably connected with a movable platform 6, and the movable platform 6 is fixedly connected with a stepping motor 7, and the power of the stepping motor 7 A mechanical clip 8 is fixedly connected to the output end, an electric slide rail 9 is laid on the top of the longitudinal slide rail 2, a slide table 10 is slidably connected to the electric slide rail 9, and a rolling cylinder 11 is connected to the slide table 10 in rotation, and the rolling cylinder 11 An elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com