Conductive rubber roller producing and manufacturing device

A technology for manufacturing a device and a rubber roller, which is applied in the field of manufacturing devices for guiding rubber rollers, can solve the problems of wasting manpower, manual feeding, etc., and achieve the effects of improving the mixing effect, improving the uniformity, and improving the discharging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-6 The application is described in further detail.

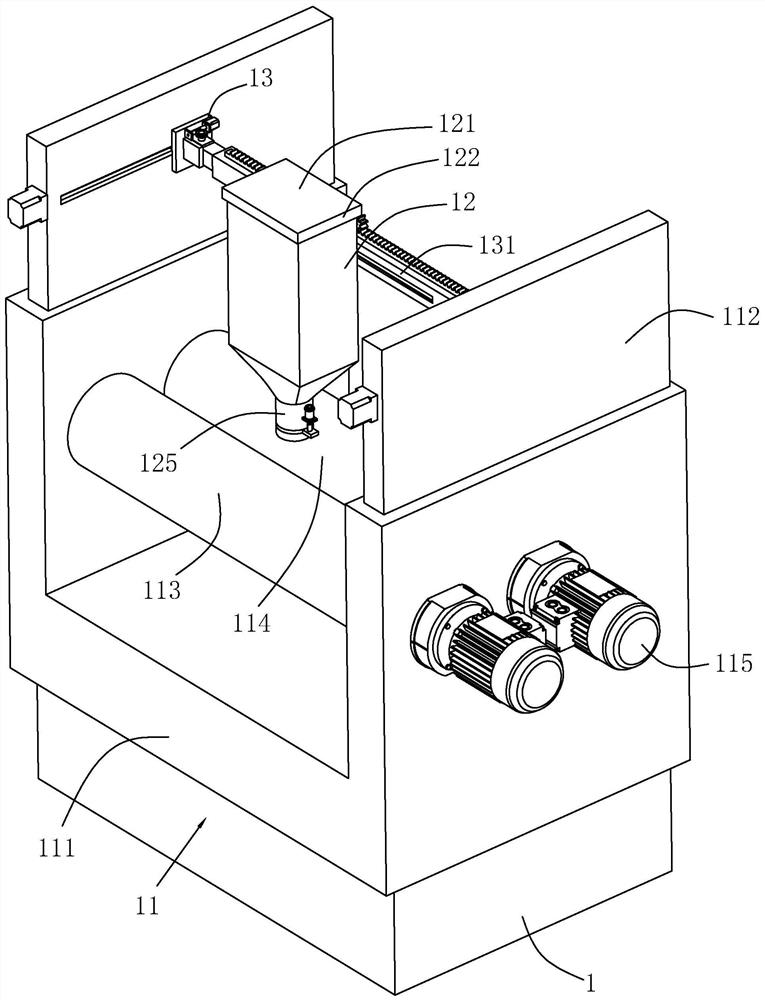

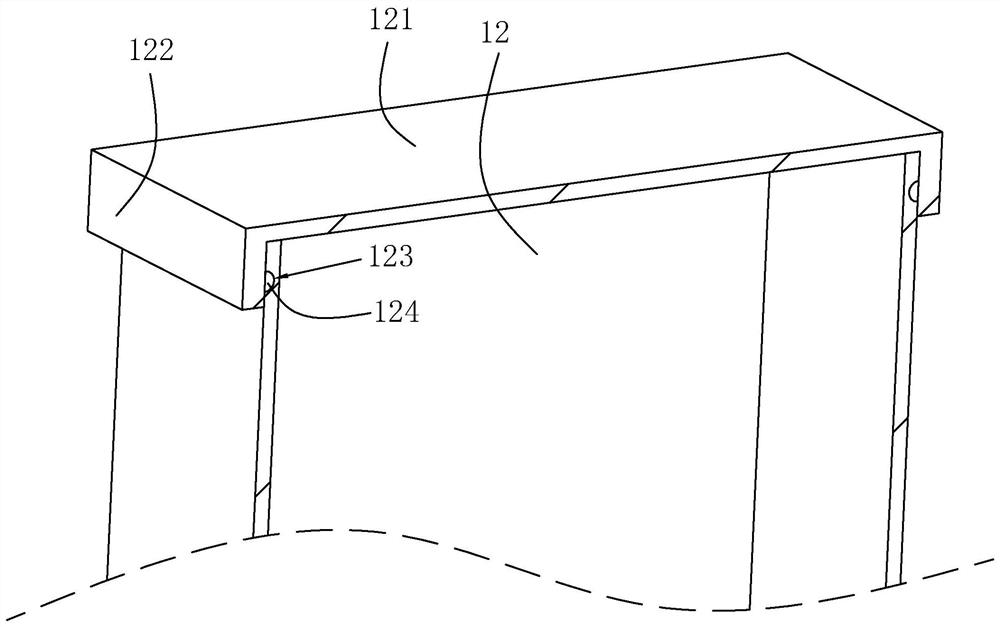

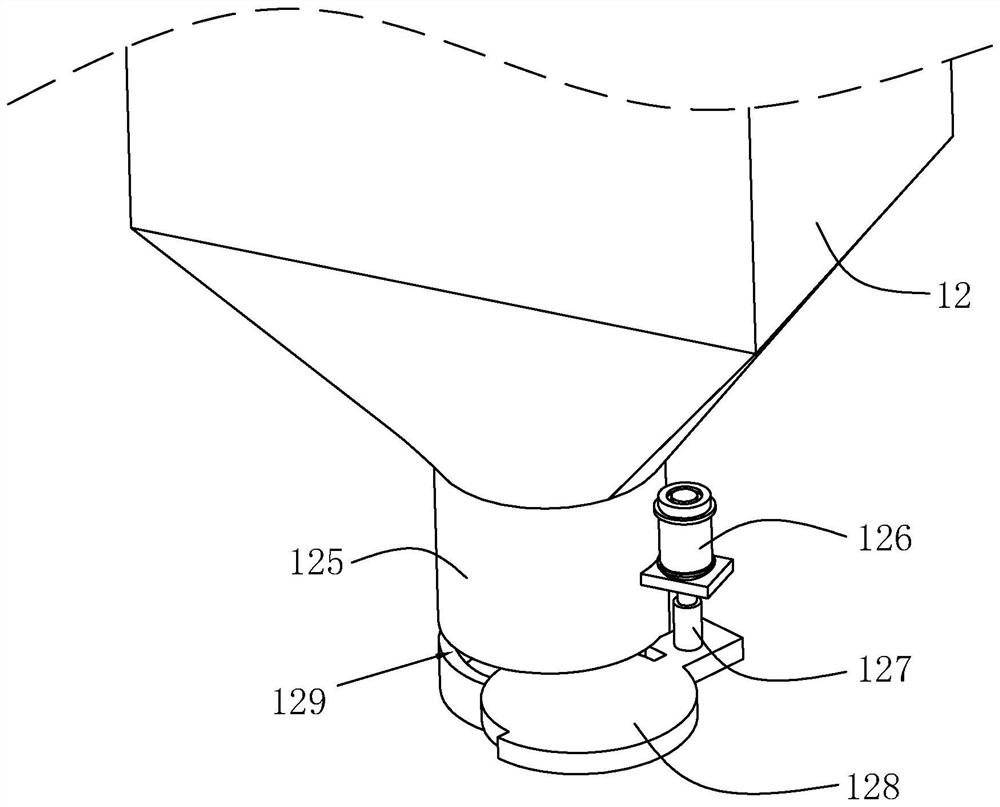

[0039] The embodiment of the present application discloses a conductive rubber roller manufacturing device. refer to figure 1 , a conductive rubber roller production and manufacturing device, including a base 1, a frame body 11 is arranged on the base 1, the frame body 11 includes a bottom plate 111 and side plates 112 perpendicular to the bottom plate 111 and located on both sides of the bottom plate 111, the side plates 112 on both sides A first roller 113 and a second roller 114 are arranged to rotate between them, and a driving mechanism for driving the rotation of the first roller 113 and the second roller 114 is arranged on the side plate 112. There are two rotating motors 115 on the surface of the plate 112 facing away from the other side plate 112, and the two rotating motors 115 are used to drive the first roller 113 and the second roller 114 on both sides to rotate in dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com