Method for vacuum brazing of large-size outer ring welding assembly

A welding component and large-size technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that cannot meet the research and trial production requirements of large-size outer ring welding components, and meet the vacuum brazing gap requirements and optimize the process Parameters, the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

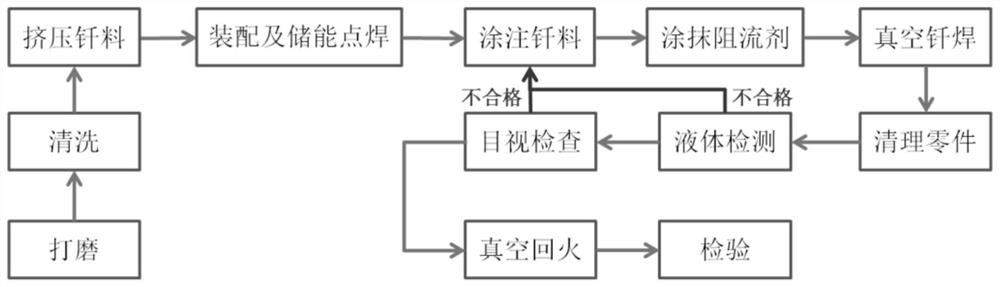

[0053] The invention discloses a method for vacuum brazing a large-size martensitic stainless steel outer ring welding assembly, which specifically includes the following steps:

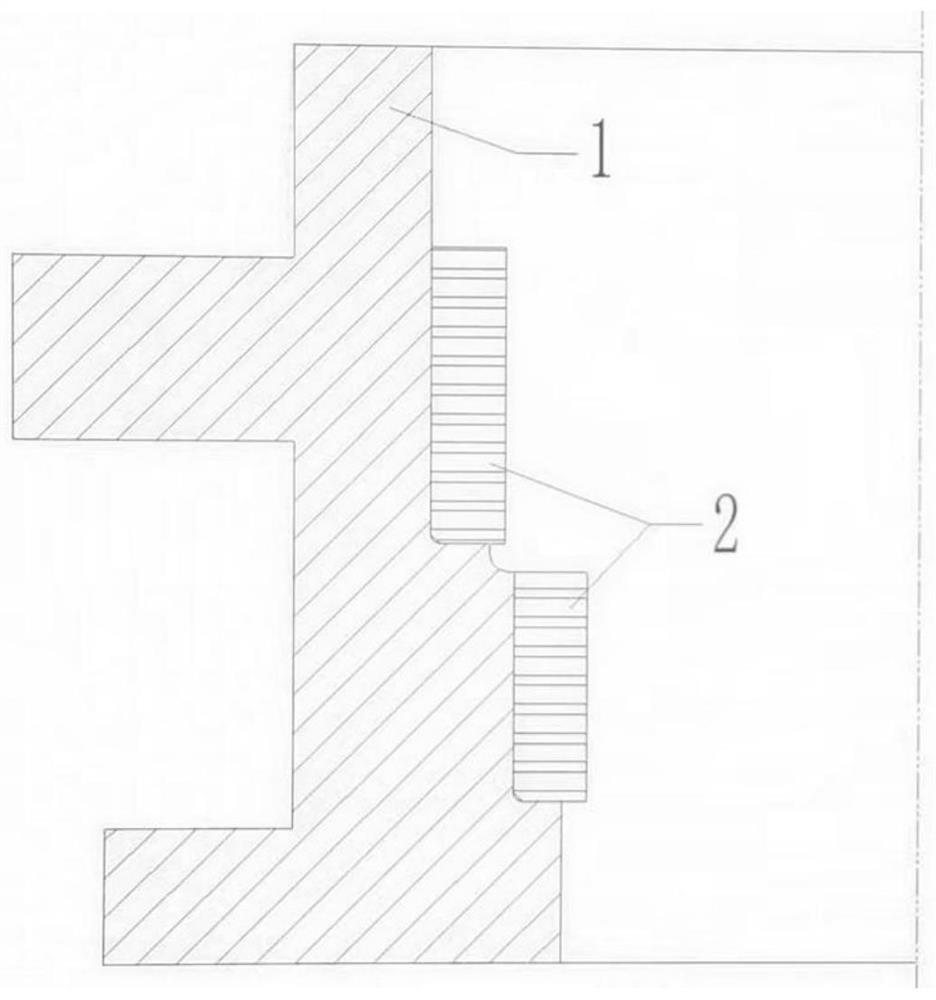

[0054] Step 1. Polishing: use a steel wire wheel to polish the portion to be welded of the annular honeycomb 2 on the surface of the outer ring substrate 1 until fresh metallic luster is exposed.

[0055] Step 2. Cleaning: Clean the surface of the part with clean acetone, and then dry the part. The surface of the cleaned part should be free of oil and other dirt.

[0056] Step 3. Extruding the solder: use a solder extruder to squeeze the strip-shaped solder into the cells of the annular honeycomb 2, and then scrape off excess solder on the surface of the annular honeycomb 2 until the metallic luster is exposed.

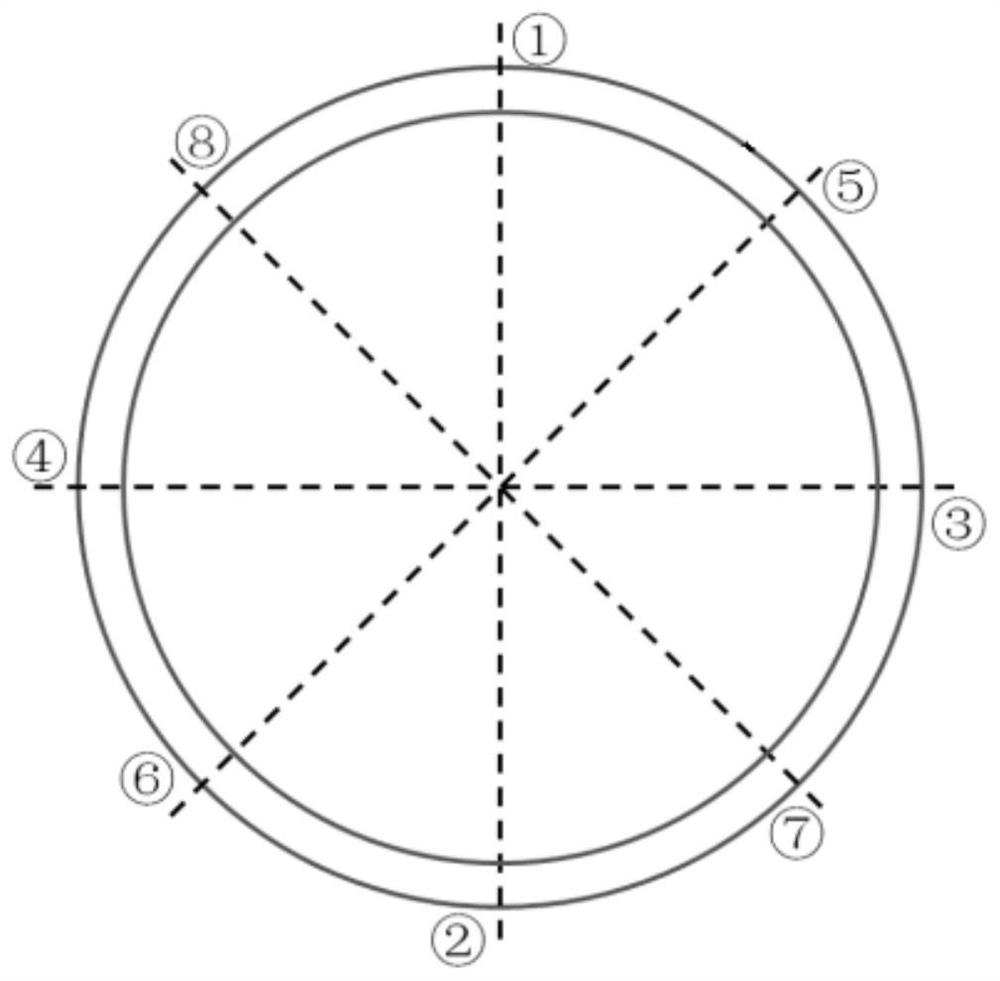

[0057] Step 4. Assembly and energy storage spot welding: pre-coat a ring of prepared solder paste on the outer ring base 1, put the ring-shaped honeycomb 2 pressed with solder into the outer...

Embodiment 2

[0070] The invention discloses a method for vacuum brazing a large-size martensitic stainless steel outer ring welding assembly, which specifically includes the following steps:

[0071] Step 1. Polishing: use a steel wire wheel to polish the portion to be welded of the annular honeycomb 2 on the surface of the outer ring substrate 1 until fresh metallic luster is exposed.

[0072] Step 2. Cleaning: Clean the surface of the part with clean acetone, and then dry the part. The surface of the cleaned part should be free of oil and other dirt.

[0073] Step 3. Extruding the solder: use a solder extruder to squeeze the strip-shaped solder into the cells of the annular honeycomb 2, and then scrape off excess solder on the surface of the annular honeycomb 2 until the metallic luster is exposed.

[0074] Step 4. Assembly and energy storage spot welding: pre-coat a ring of prepared solder paste on the outer ring base 1, put the ring-shaped honeycomb 2 pressed with solder into the outer...

Embodiment 3

[0087] The invention discloses a method for vacuum brazing a large-size martensitic stainless steel outer ring welding assembly, which specifically includes the following steps:

[0088] Step 1. Polishing: use a steel wire wheel to polish the portion to be welded of the annular honeycomb 2 on the surface of the outer ring substrate 1 until fresh metallic luster is exposed.

[0089] Step 2. Cleaning: Clean the surface of the part with clean acetone, and then dry the part. The surface of the cleaned part should be free of oil and other dirt.

[0090] Step 3. Extruding the solder: use a solder extruder to squeeze the strip-shaped solder into the cells of the annular honeycomb 2, and then scrape off excess solder on the surface of the annular honeycomb 2 until the metallic luster is exposed.

[0091] Step 4. Assembly and energy storage spot welding: pre-coat a ring of prepared solder paste on the outer ring base 1 . Put the ring-shaped honeycomb 2 pressed with solder into the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com