Differential three-roller roller press

A technology of roller press and differential speed, applied in the field of differential speed three-roll roller press, can solve the problems of unfavorable energy saving, increased energy consumption, low yield of finished products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

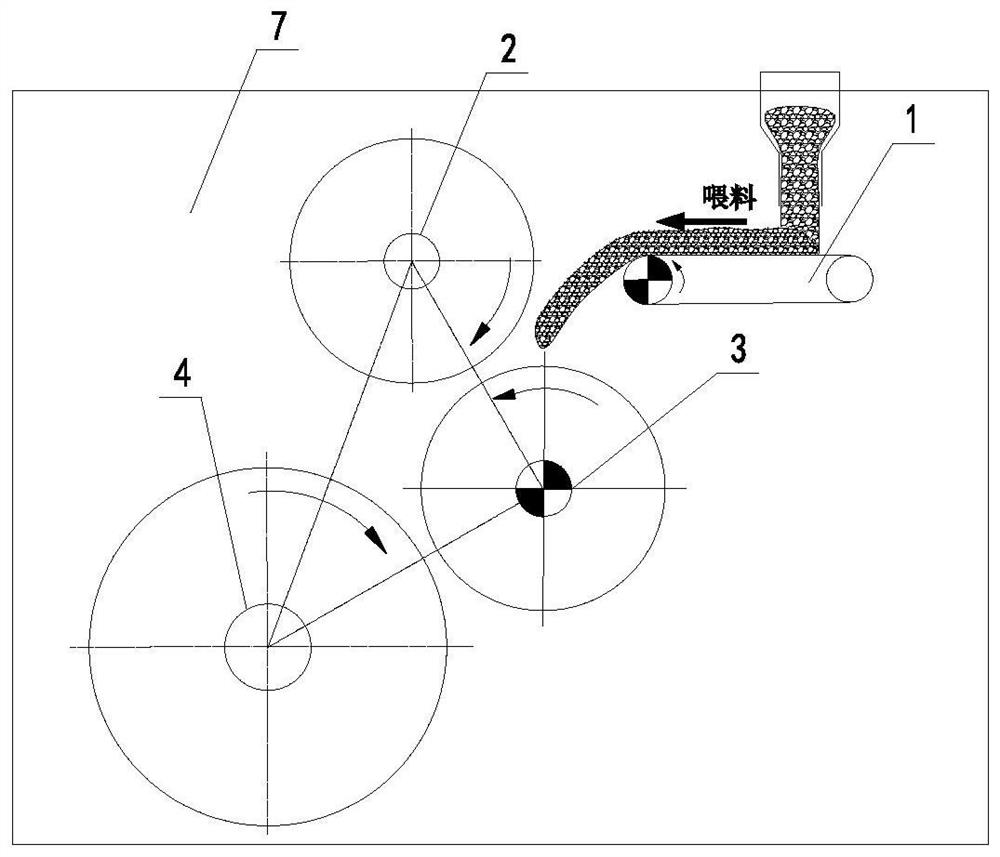

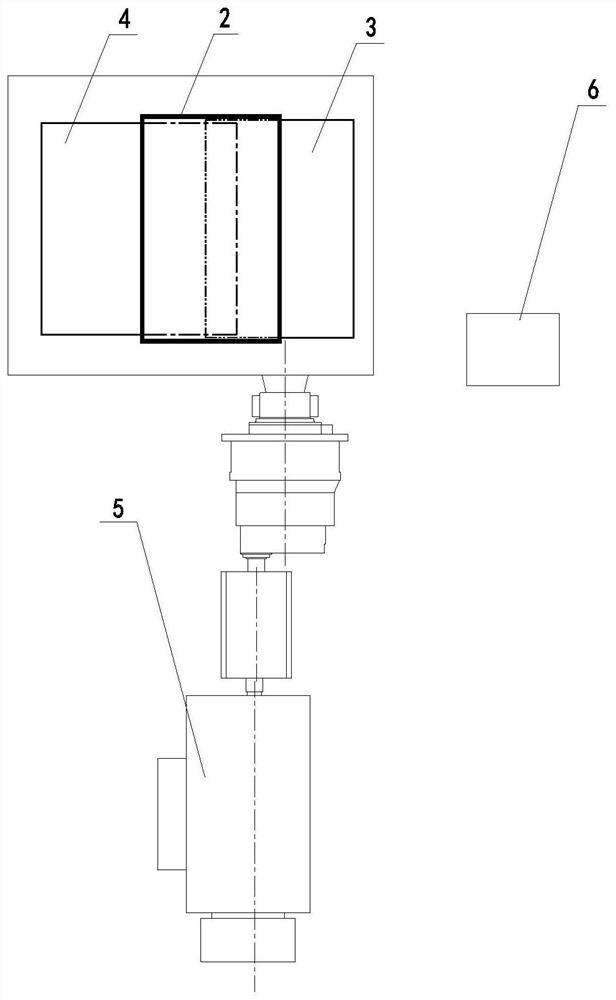

[0017] combine figure 1 and figure 2 , the specific embodiment of the present invention is described further:

[0018] A three-roller differential speed roller press, comprising a feeding device (1), an upper pressure roller (2), a movable roller (3), a lower pressure roller (4), a driving device (5), a hydraulic device (6) and The frame (7), the feeding device (1) is composed of a hopper and a horizontal conveyor belt, driven by the conveyor belt, the material is evenly and stably transported to the movable roller (3), and the movable roller (3) is connected by a reducer The driving device (5), driven by the motor, the movable roller (3) drives the upper pressure roller (2) to rotate through the material, and at the same time, the hydraulic device (6) provides a pressing force on the movable roller (3) and can adjust the movable roller and the upper pressure roller. Roller (2) and the gap between the lower pressure roller (4), so as to achieve the first layer of rolling on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com