Cyclone electrofiltration recovery device and application thereof in treatment of heavy metals in sludge

A recovery device and swirling electricity technology, which is applied in the direction of electrochemical sludge treatment, electrodialysis, sludge treatment, etc., can solve the problems of low heavy metal removal efficiency, environmental protection, and reduce heavy metal content, so as to improve the removal rate of heavy metals, Reduce migration time and improve removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

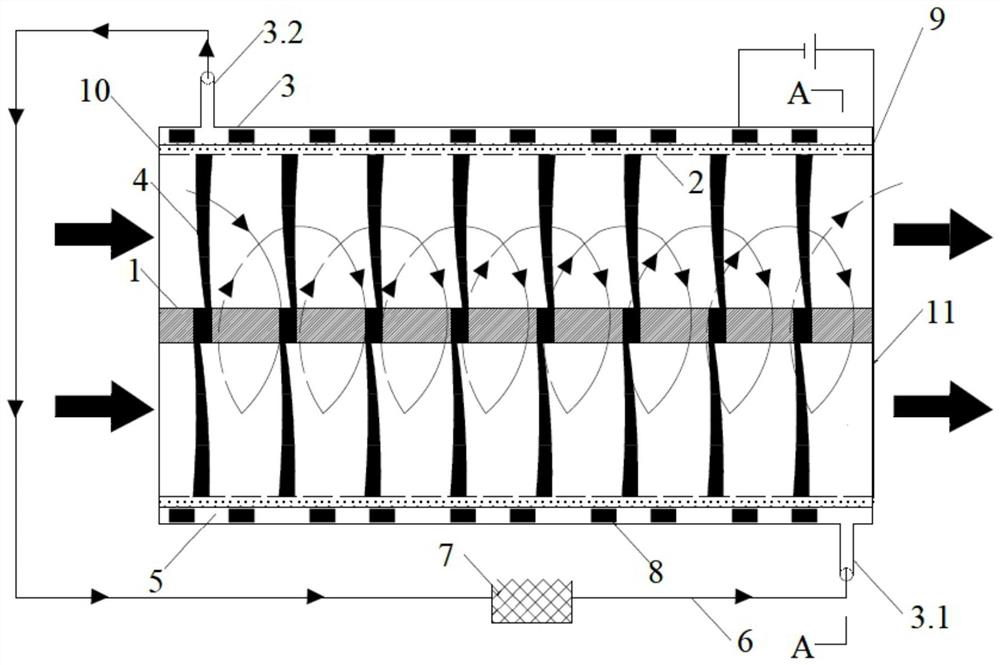

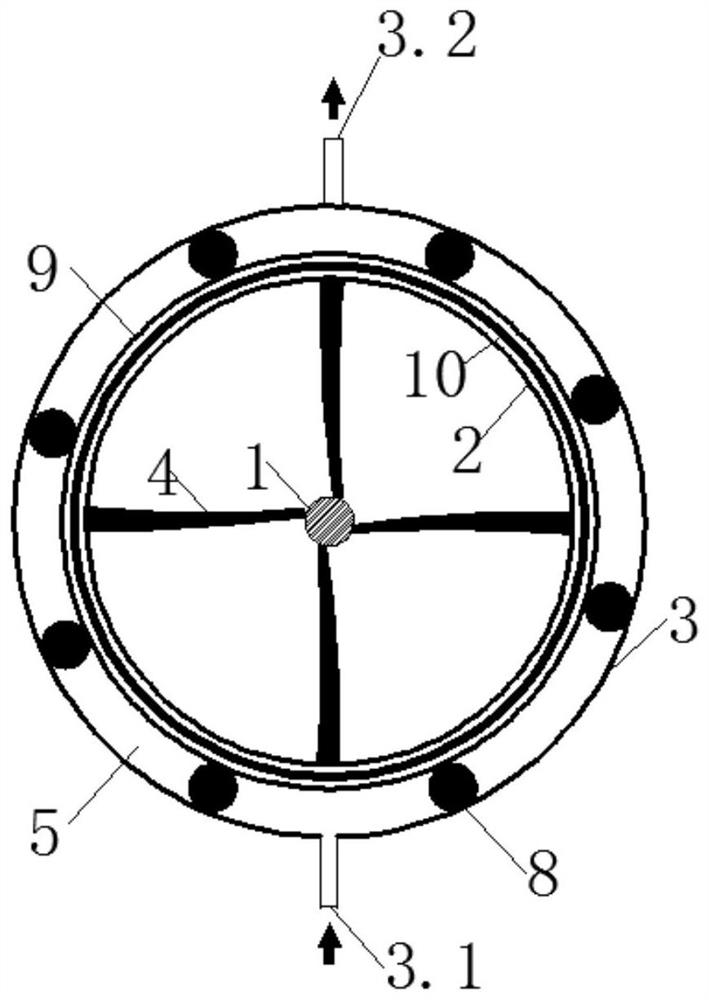

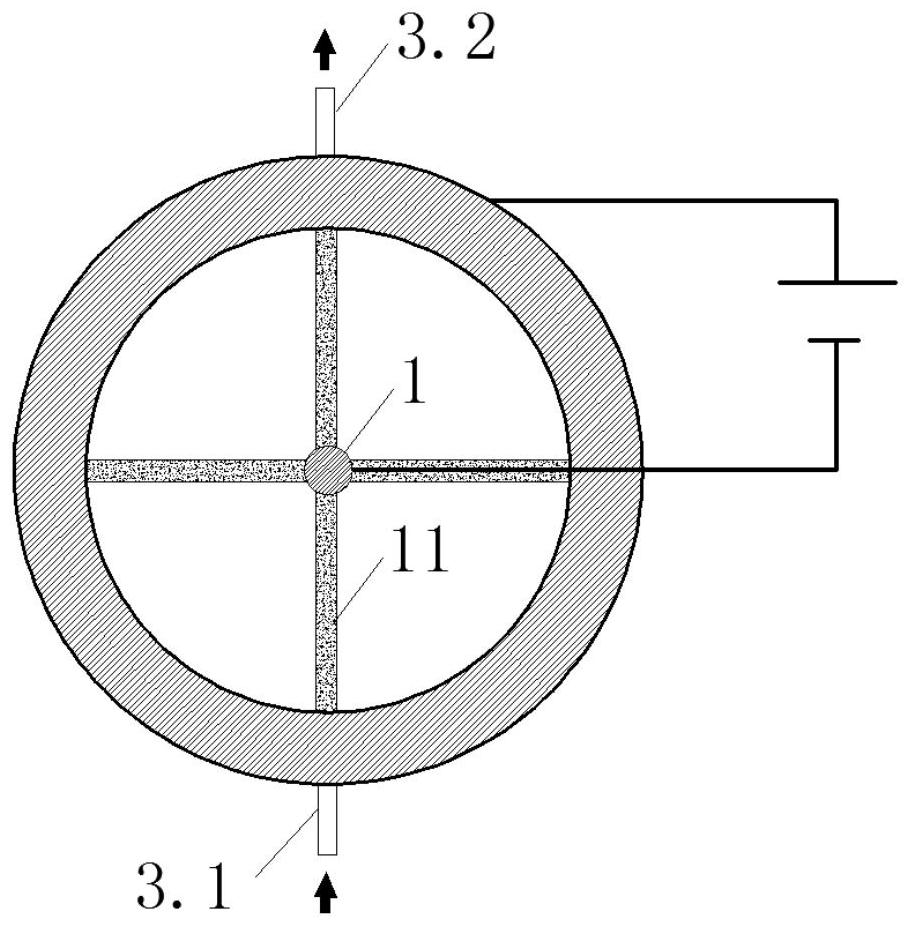

[0042] see Figure 1-3 , a cyclone electrodiafiltration recovery device, comprising cylinder, anode rod 1 (diameter is 1cm), cyclone unit, filter combination layer and catholyte circulation system, said catholyte circulation system comprises catholyte chamber 5 and circulation Pipeline 6, the axial ends of the cylinder body are set as sludge inlet and sludge outlet respectively, and the cylinder body (2m in length) includes an inner cylinder 2 (with an inner diameter of 11cm and made of poly Propylene) and an outer cylinder 3 (the inner diameter is 15cm, and the material is aluminum), between the inner cylinder 2 and the outer cylinder 3, a filter combination layer and a catholyte chamber 5 are sequentially arranged from the inside to the outside in the radial direction, in the The outer cylinder 3 is provided with a catholyte inlet 3.1 and a catholyte outlet 3.2 communicating with the catholyte chamber 5, and the two ends of the circulating pipeline 6 are respectively connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Filter pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com