Potted Strawberry Harvesting Device

A harvesting device, strawberry technology, applied in the direction of harvesters, container cultivation, agricultural machinery and machinery, etc., can solve the problems of difficulty in picking and harvesting, excessive labor, and easy damage, so as to avoid strawberry picking work, avoid damage, The effect of solving picking work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

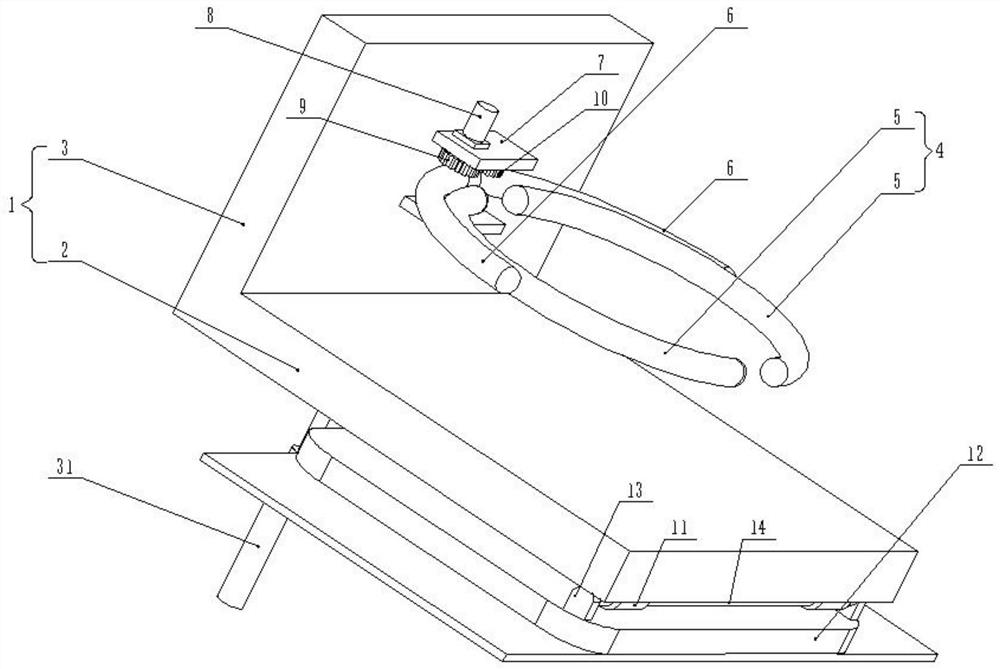

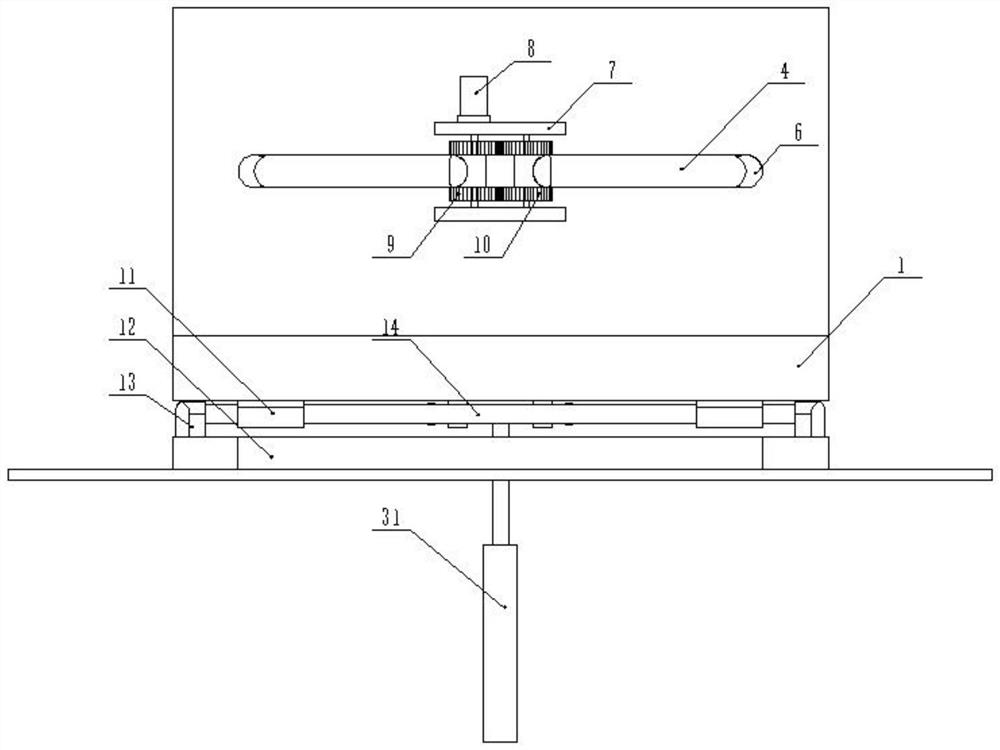

[0043] The application relates to a strawberry harvesting device, especially for picking and harvesting potted strawberries, which is different from picking manipulators such as apples and kiwis.

[0044] The application includes a strawberry pot conveying device, a strawberry picking device and a strawberry conveying device, especially the strawberry pot conveying device and the strawberry picking device are the core of the application, both of which are the core equipment of the strawberry picking process.

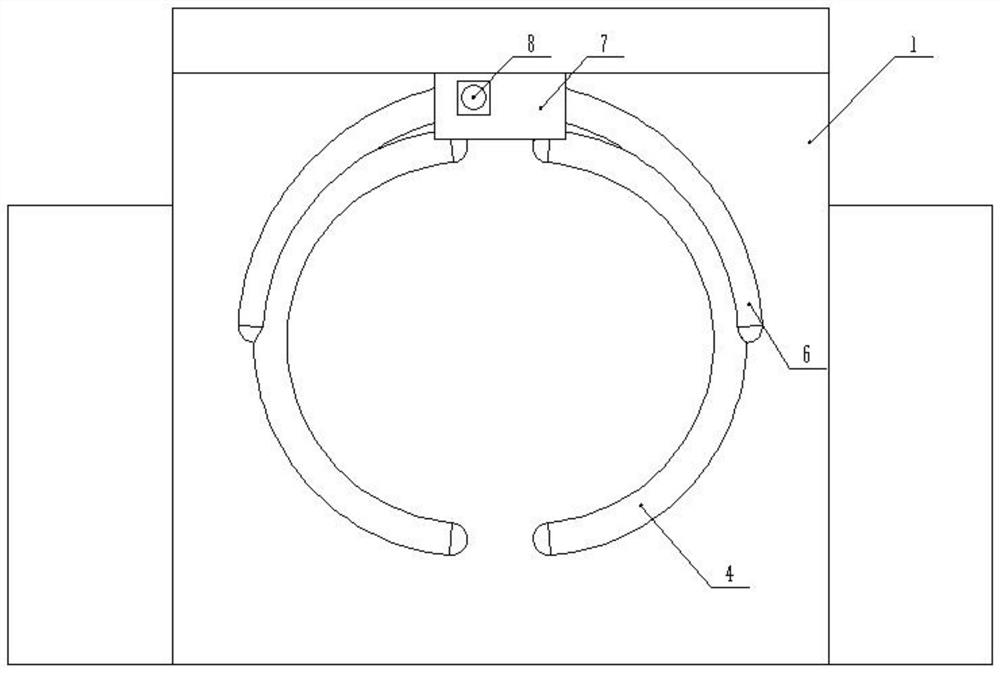

[0045] Strawberry pot conveying device comprises L-shaped support plate 1, wherein, L-shaped support plate 1 comprises a support base plate 2 and a side support plate 3, side support plate 3 is fixed on the side of support base plate 2 upper ends, on the side of support base plate 2 The top is provided with holding ring 4, and in the present embodiment, holding ring 4 comprises 2 arc-shaped holding hoops 5, and a connecting rod is installed on the outside of holding hoop ...

Embodiment 2

[0061] Strain gauges are installed on the ring structure 21. When the strawberry enters the flexible protection net, the flexible protection net will generate a compressive stress signal to the strain gauge. The controller receives the compressive stress signal and controls the rotation of the second driving device 19. Sensor is installed on the main body of conveying track, flexible conveyor belt device, so that detect the corresponding position of rotating disk 18, for example, sensor is an infrared sensor, and the induction sheet that cooperates with infrared sensor is fixedly installed below rotating disk 18, and each induction sheet Corresponding to an annular structure 21, take the sensor installed on the main body of the flexible conveyor belt device as an example. When the rotating disk 18 rotates to the flexible conveyor belt, the sensor senses the position signal of the rotating disk 18, and then the controller receives the signal and sends it to The controller contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com