SAW-BAW hybrid resonator

A SAW-BAW, hybrid resonator technology, applied in electrical components, impedance networks, etc., can solve the problem of high cost, achieve the effect of high Q value, structural optimization design suppression, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

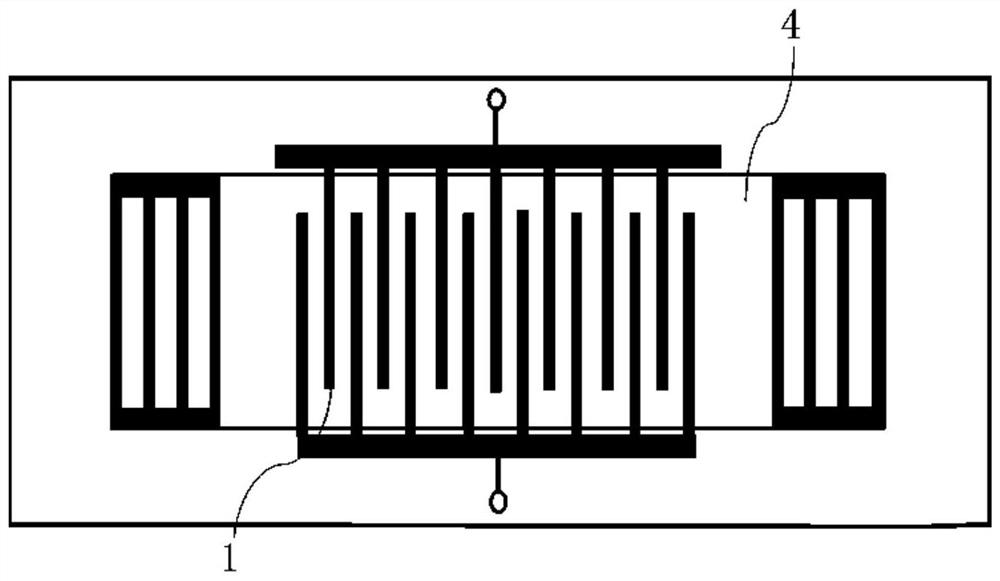

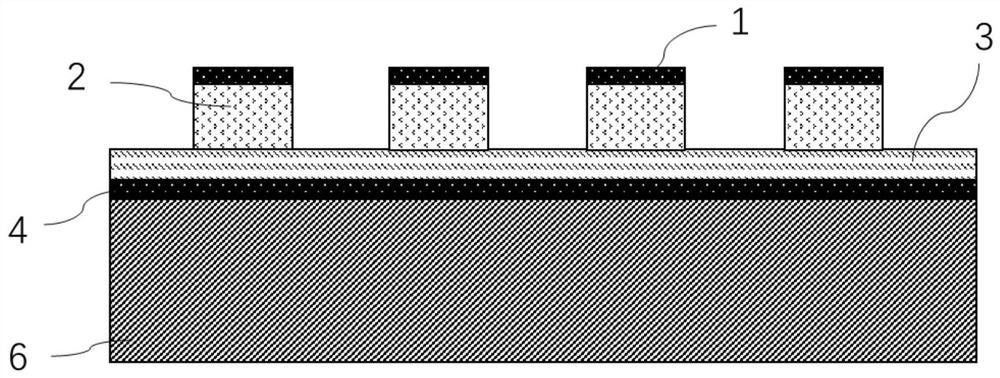

[0052] A SAW-BAW hybrid resonator, such as figure 1 with 2 As shown, it includes a first electrode layer 1, a first piezoelectric film layer 2, a second piezoelectric film layer 3, a second electrode layer 4 and a substrate layer 6 arranged in sequence;

[0053] The orthographic projection of the first electrode layer 1 and the first piezoelectric film layer 2 on the substrate layer 6 coincides, the second piezoelectric film layer 3 coincides with the orthographic projection of the second electrode layer 4 on the substrate layer 6, and the first electrode layer The orthographic projection of 1 on the substrate layer 6 is located within the orthographic projection of the second electrode layer 4 on the substrate layer 6, and the overall periodic and equidistant arrangement of the first electrode layer 1 and the first piezoelectric thin film layer 2 Two piezoelectric film layers 3;

[0054] The material of the first electrode layer 1 and the second electrode layer 4 is Pt, and...

Embodiment 2

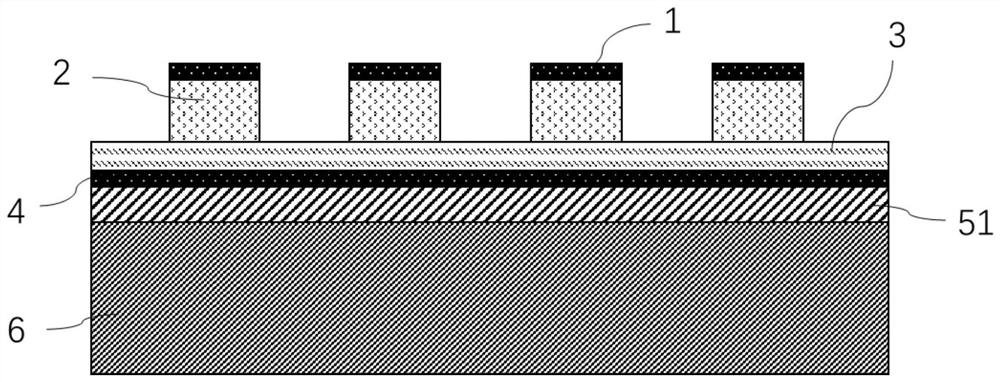

[0059] A SAW-BAW hybrid resonator, such as image 3 As shown, its structure is basically the same as that of Embodiment 1, the difference is that it also includes a low acoustic impedance layer 51 located between the second electrode layer 4 and the substrate layer 6, and the low acoustic impedance layer 51 is SiO 2 film, SiO 2 The normalized thickness of the membrane h SiO2 Satisfy the following relationship: 0.1λ≤h SiO2 ≤λ.

Embodiment 3

[0061] A SAW-BAW hybrid resonator, such as Figure 4 As shown, its structure is basically the same as that of Embodiment 1, except that it also includes an acoustic reflective layer 5 located between the second electrode layer 4 and the substrate layer 6;

[0062] The acoustic reflection layer 5 includes a low acoustic impedance layer 51 and a high acoustic impedance layer 52 (the sound velocity of the low acoustic impedance layer is less than that of the high acoustic impedance layer), and the low acoustic impedance layer 51 is closer to the second electrode than the high acoustic impedance layer 52 Layer 4;

[0063] The low acoustic impedance layer 51 is SiO 2 film, SiO 2 The normalized thickness of the membrane h SiO2 Satisfy the following relationship: 0.1λ≤h SiO2 ≤λ;

[0064] The high acoustic impedance layer 52 is an AlN film, and the standardized thickness h of the AlN film is AlN Satisfy the following relationship: 0.1λ≤h AlN ≤λ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com