A steel strip product whole-process quality control and automatic grade judgment method

A full-process and product technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of incomplete process product quality judgment, automatic judgment, and unsatisfactory, so as to improve product quality control and enterprise The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

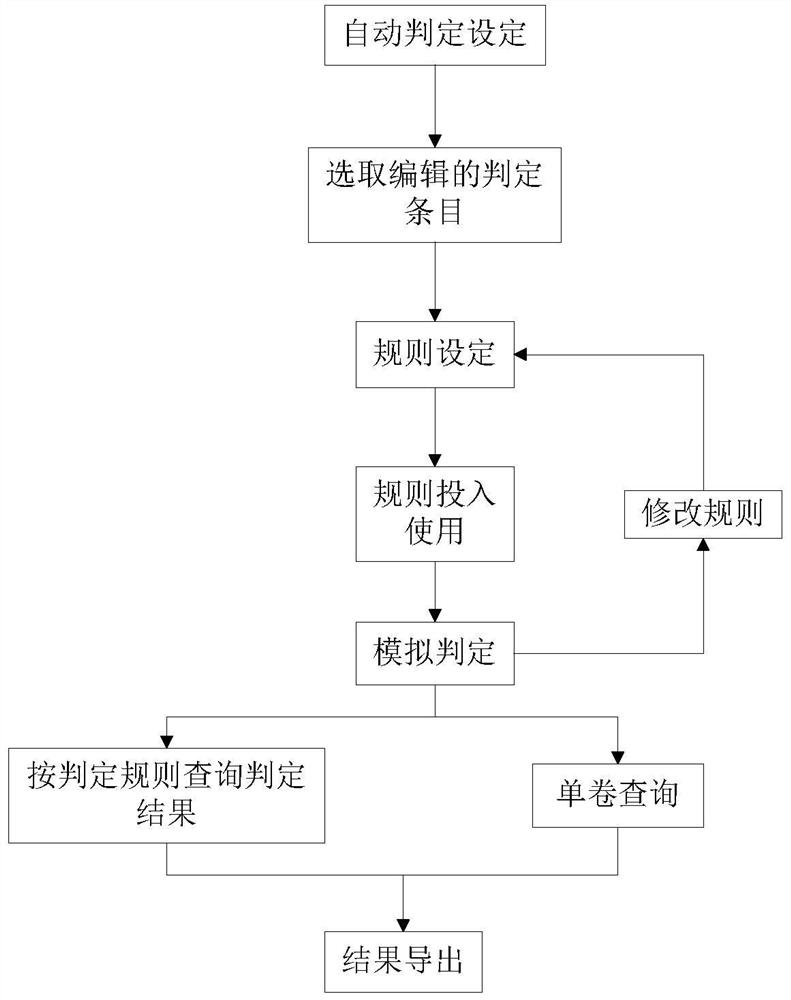

Method used

Image

Examples

Embodiment

[0076] EXAMPLES: A user ordering the standard Q / HG 032-2018, a license number HC250IF, a specifications 1.2 * 1163mm.

[0077] The first step is based on the user's demand information as the delivery standard for chemical composition, mechanical performance and other indicators use the enterprise standard Q / HG 032-2018, thickness tolerance adopts standard PT.a GB / T 709-2019 general precision, width tolerance adopts standard PW.A GB / T 709-2019 Normal Accuracy, according to customer requirements, the micro-negative tolerance is taken.

[0078] The second step is converted to the production process information according to the delivery standard. The performance requirements in delivery standards are 250-360MPa, tensile strength ≥440MPa, etc., Q / HG 032-2018 standard ingredients require C ≤ 0.008%, Si ≤ 0.8%, Mn ≤ 1.2%, etc., to meet user performance requirements The ingredients were tamperized to control C ≤ 0.004%, the Si content was 0.4-0.5%, the Mn content was 0.6-0.8%. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com