Method for judging one-way sweat guiding performance of fabric material

A technology of fabric materials and determination methods, which is applied in the direction of analyzing materials, suspension and porous materials, and using material absorption and weighing. It can solve the problems that peripheral electrodes cannot detect changes in resistance, are incorrect, and have poor diffusion capabilities. , to achieve the effect of accurate measurement and judgment results and scientific methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in combination with specific embodiments.

[0034] The assays that implement the embodiments of the invention are based on the following systems:

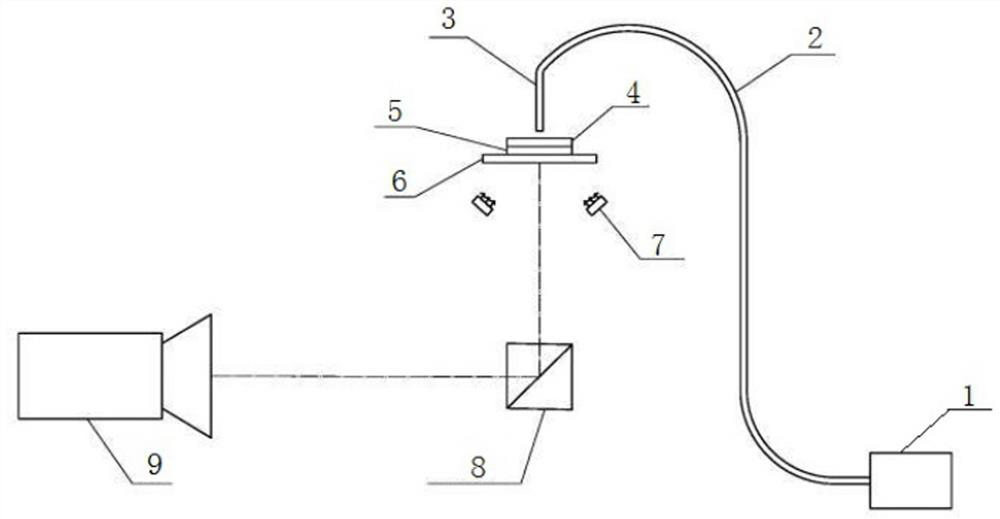

[0035] A subsystem including a precise quantitative and constant speed delivery of simulated sweat, a liquid volume sensor, a sample stage, an irradiation device, a mirror, an image acquisition subsystem, a signal transmitter and an image and data processing subsystem , wherein the liquid volume sensor, sample stage, irradiation device, and image acquisition subsystem are all isolated from external light, and the subsystem for delivering simulated sweat with precise quantitative and constant speed includes a precision infusion pump, a delivery tube, and an infusion solution The precision infusion pump can accurately quantify and deliver the simulated sweat containing the ultraviolet fluorescent indicator to the infusion head through the delivery tube at a fixed speed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com