Sandy silt subgrade filling construction method and application thereof

A construction method and soil roadbed technology, which can be applied to buildings, roads, roads, etc., can solve the problems of not being able to effectively improve the freeze-thaw cycle resistance of sandy silt roadbeds, so as to improve the freeze-thaw cycle resistance, improve pulverization and The effect of peeling off skin and corners and reducing volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] As another preferred embodiment of the present invention, the preparation method of the curing agent comprises the following steps:

[0048] 1) Mix triethanolamine, silicone wetting and dispersing agent, sodium metaaluminate, retarder and part of water to obtain primary mixture;

[0049] 2) mixing the primary mixture obtained in step 1) with water glass to obtain a premix;

[0050] 3) Mix the premixed material obtained in the step 2) with the curing material and the remaining part of water, and carry out a metathesis reaction to obtain a curing agent.

[0051] As another preferred embodiment of the present invention, in the preparation method of the curing agent, based on the total amount of water being 35-55 parts by weight, the part of water in the step 1) is 15-20 parts by weight.

[0052] Preferably, the preparation method of described curing agent comprises the following steps:

[0053] 1) In parts by weight, mix 2 parts of triethanolamine, 0.5 parts of IOTA245, ...

Embodiment 1

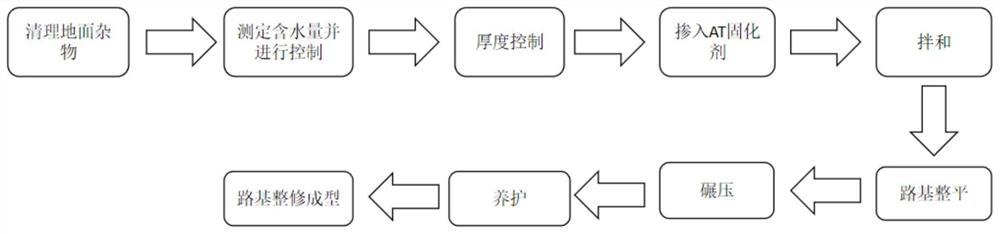

[0060] A sandy silt subgrade filling construction method, specifically a method of using an AT curing agent for solidifying sandy silt to carry out subgrade filling construction, refer to figure 1 , which includes the following steps:

[0061] Step 1: Level and fill the earthwork in the construction area where the roadbed filling construction is to be carried out, and clean up the weeds, garbage and other sundries in the construction area of the roadbed.

[0062] Step 2: Measure the moisture content of the sandy silt (roadbed filler) to be filled into the construction area, and compact the silt according to the compaction test plan in T0131-2006 of "JTG3430-2020 Highway Soil Test Regulations" In the experiment, for each moisture content, three groups of parallel experiments were carried out, and finally the moisture content-dry density relationship curve was drawn to determine the optimum moisture content.

[0063] Step 3: Water content control, observe whether the sandy si...

Embodiment 2

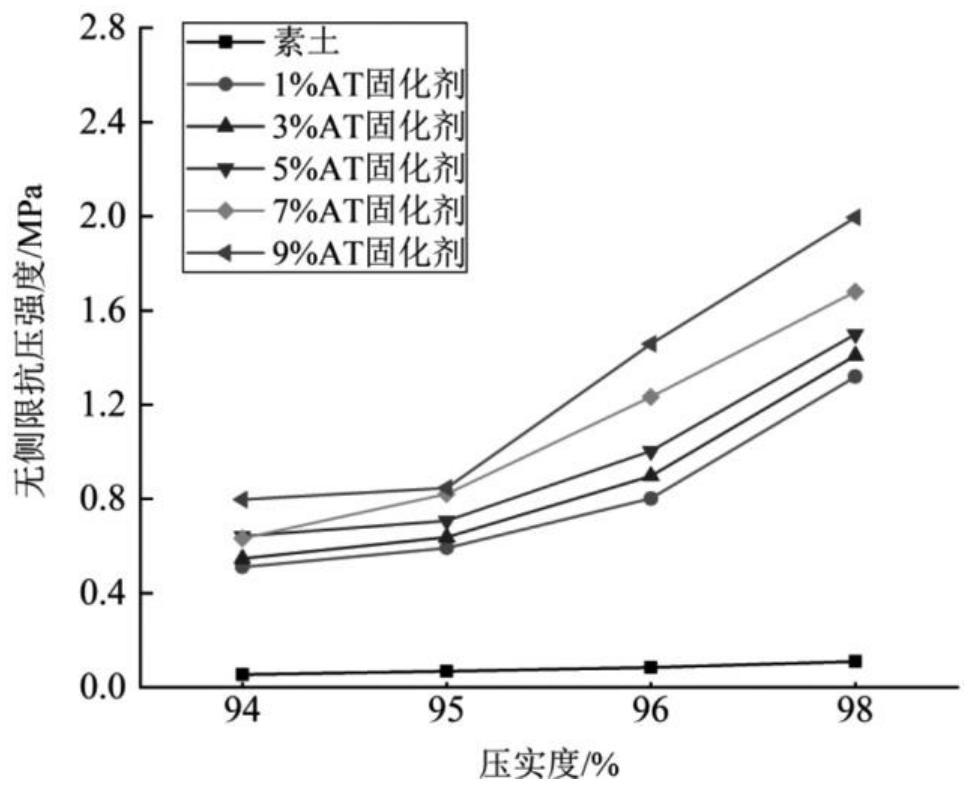

[0077] Referring to the sandy silt subgrade filling construction method in Example 1, the dosage of AT curing agent (modulus 3.3) is set to (calculated according to mass percentage) 0%, 1%, 3%, and 5% respectively , 7%, 9%, and make samples with different compaction degrees (respectively 94%, 95%, 96% and 98%), and then conduct the unconfined compressive strength test, the specific unconfined compressive strength See the test results figure 2 As shown, among them, three groups of parallel tests were carried out according to the requirements of the specification, and the optimum moisture content was 11.4%, and the maximum dry density was 1.873g / cm 3 , that is, a sample with a mass of 205 g is considered to have reached the relative maximum degree of compaction. The preparation method of the unconfined compressive strength sample is carried out in accordance with the provisions of the "Test Regulations for Highway Engineering Inorganic Binder Stable Materials (JTG E51-2009)" i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com