Vertical pouring type solidified soil embankment construction mold and method

A construction method and technology for solidifying soil, applied in roads, buildings, roads, etc., can solve problems such as many processes, uneven settlement and other problems, and achieve the effect of less subgrade processes, reducing grading angle, and avoiding embankment cracking and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

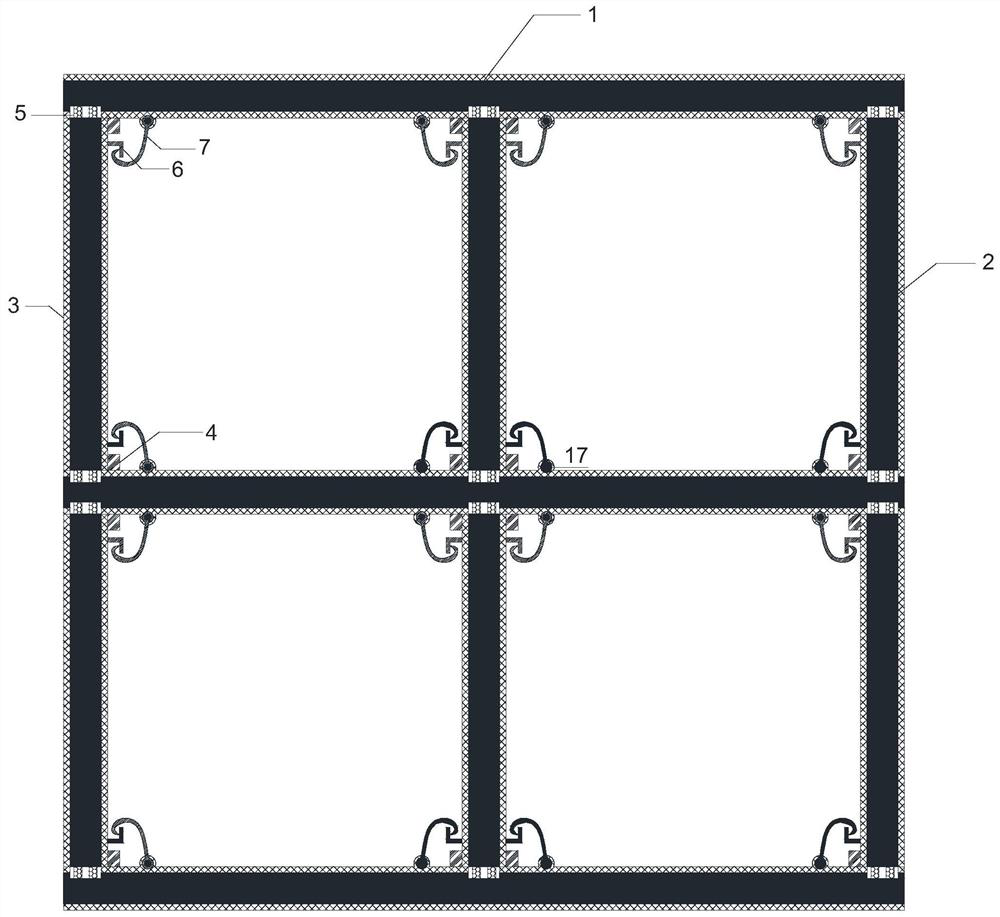

[0044] Such as figure 1 , a construction mold for vertical pouring solidified soil embankment, comprising three longitudinal formworks and six transverse formworks, the three longitudinal formworks are arranged in parallel and at intervals, three transverse formworks are arranged at intervals between two adjacent longitudinal formworks, and three The vertical template and six horizontal templates are integrally enclosed to form a frame structure of matts.

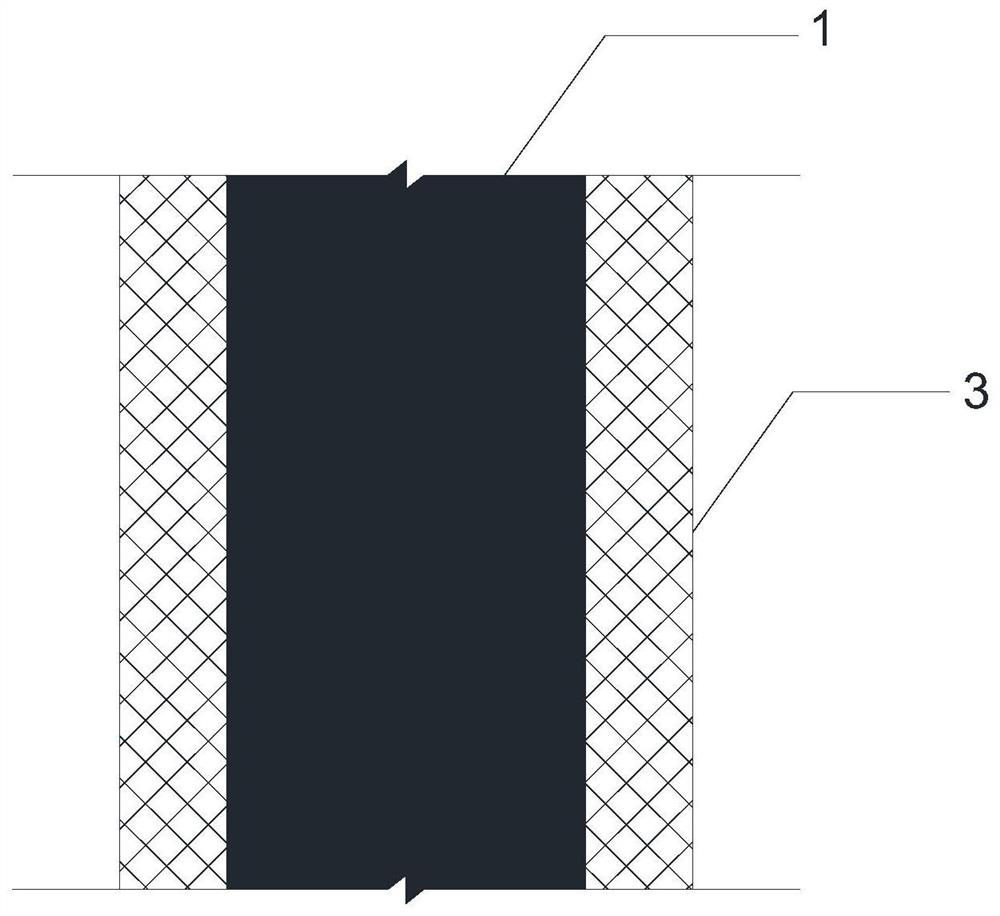

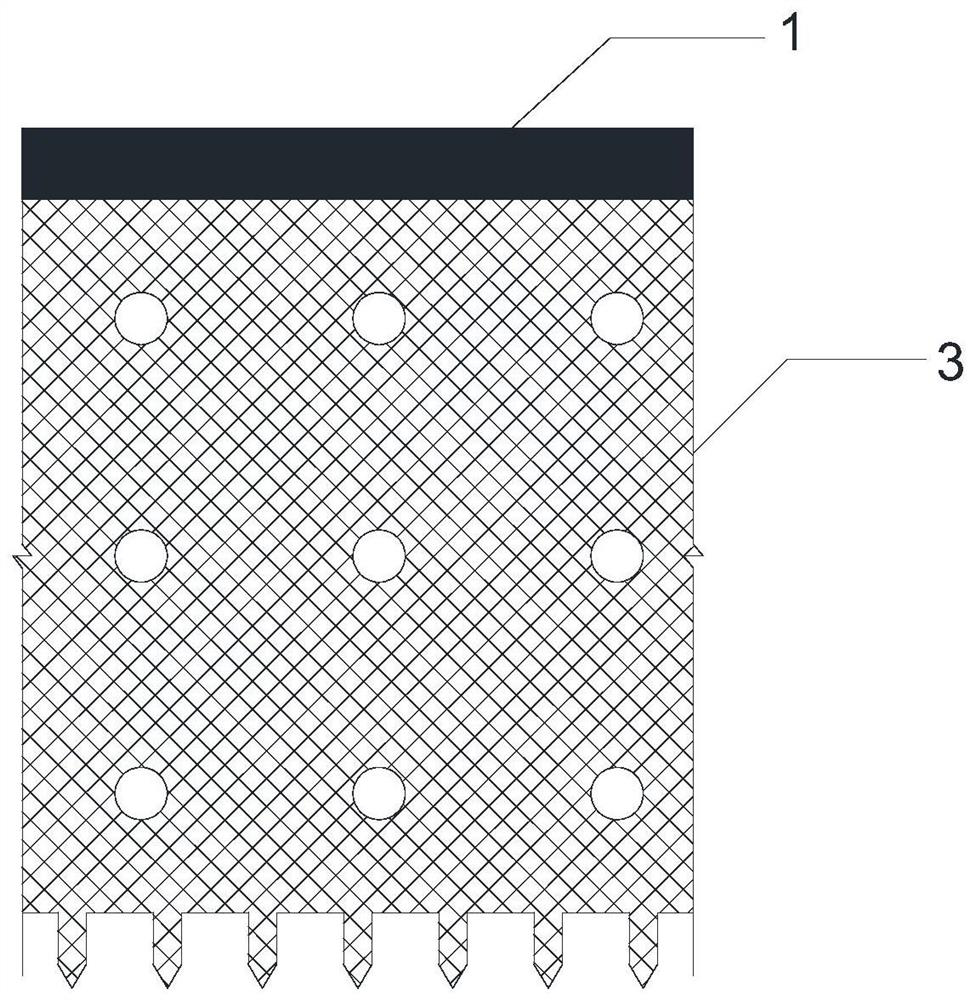

[0045] Such as Figure 2-4 , the longitudinal formwork is PP plate, plastic geogrid is laid on both sides of the PP plate, grooves are separated on the longitudinal formwork, and a pair of sealing strips are fixed near the groove, and a pair of sealing strips are located on both sides of the groove. On the side, the distance between a pair of sealing strips is the thickness of the horizontal formwork, and a hook is hinged near each sealing strip on the longitudinal formwork. Located at the grooves at both ends of the long...

Embodiment 2

[0055] A construction method for vertical pouring solidified soil embankment, comprising:

[0056] Step 1. Transport the prepared formwork to the site, insert the formwork into the foundation according to the site conditions, and prepare the silt waste soil and inorganic curing agent required for the preparation of fluid filling;

[0057] Step 2: Preparation of fluid filler: Aiming at the initial water content of the silt waste soil (generally greater than 80%), adding an appropriate amount of cement or lime, so that the fluidity and self-compacting properties of the fluid solidification waste soil meet the design requirements.

[0058] Step 3. Before the pouring of the fluid filler, level and tamp the pouring area, release the embankment sideline, insert the longitudinal formwork with the sealing strip into the foundation soil manually, and press all the insertion strips at the lower end of the longitudinal formwork into the ground Stop pressing after the following, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com