Durable polyvinylidene fluoride three-layer composite hydrophilic film and preparation method thereof

A technology of polyvinylidene fluoride and layer compounding, which is applied in general water supply saving, rayon manufacturing, filament/thread forming, etc., can solve the problems of poor durability, achieve hydrophilicity, simple operation process, and small pore size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) PVDF, hydrophilic SiO 2 Dissolve in DMF and acetone, heat and stir for 4 hours, then stir without heating for 20 hours, after fully stirring, make the concentration of PVDF in the solution 10wt%, hydrophilic SiO 2 The quality of ,: the quality of PVDF=1:100, the quality of DMF: the quality of acetone=1:1;

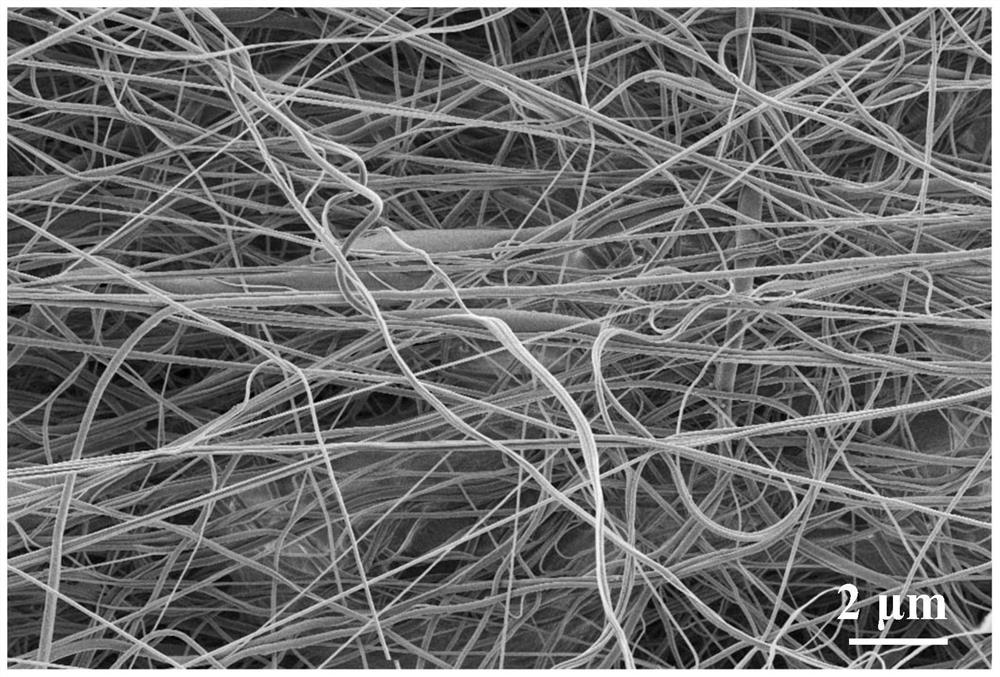

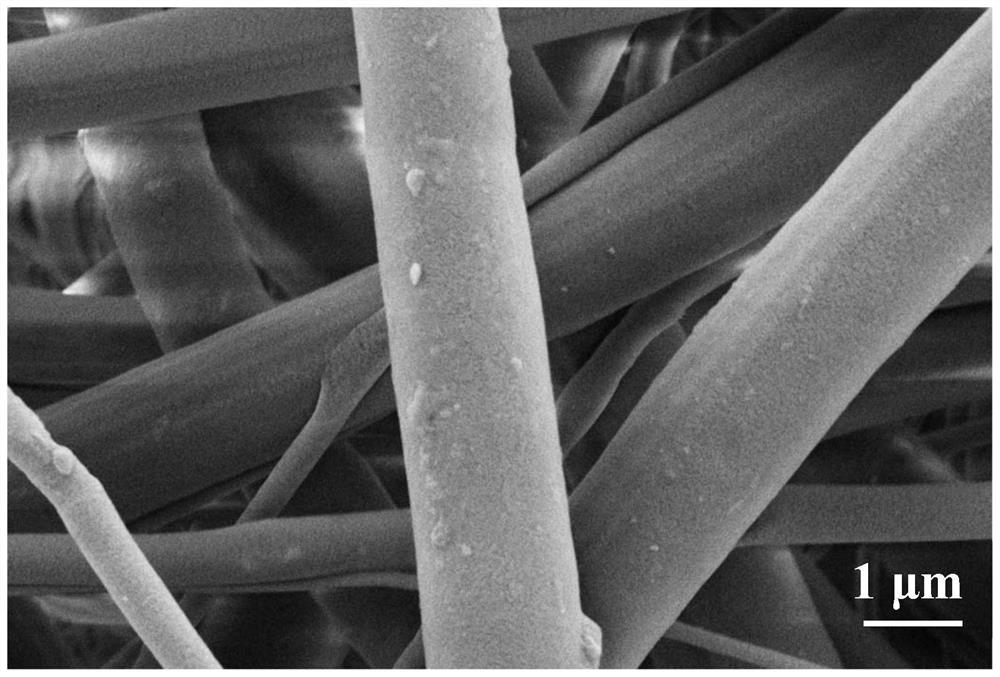

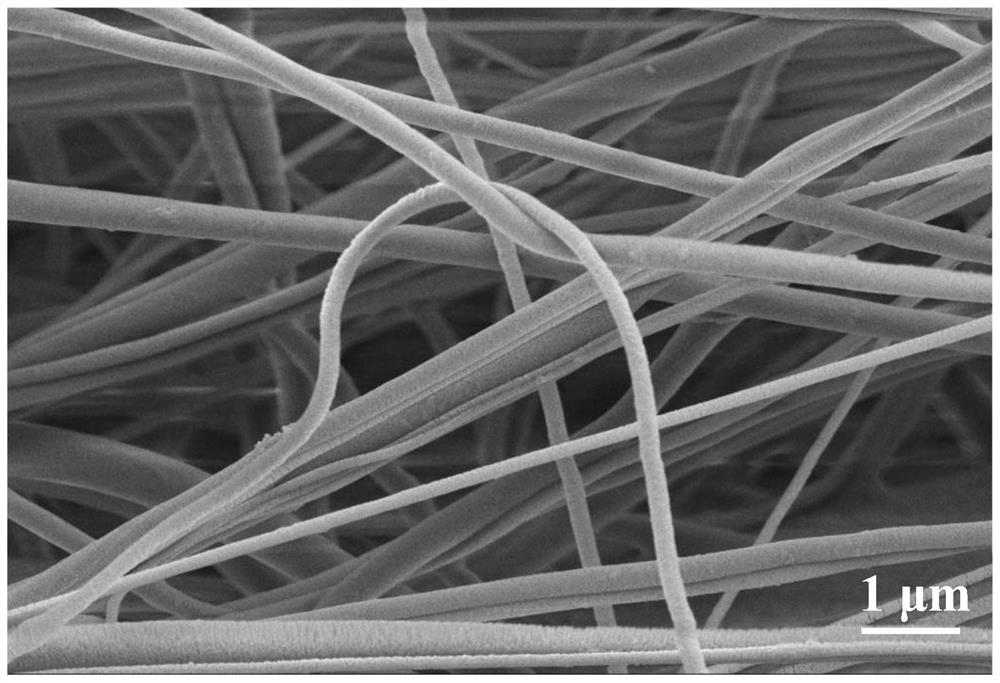

[0029] (2) Electrospinning is carried out with the solution obtained in step (1), and the electrospinning process parameters are adjusted. The first layer uses 20KV voltage, 0.8ml / h advancing rate, 14cm receiving distance, 400r / min, and the spinning time is 2h. The second layer uses 15KV voltage, 2ml / h propulsion rate, 9cm receiving distance, 300r / min, spinning time is 2h, the third layer uses 20KV voltage, 0.8ml / h propulsion rate, 14cm receiving distance, 400r / min, spinning The silk time is 2 hours, so that a thick and thin three-layer composite PVDF nano-membrane is formed;

[0030] (3) Add PVP and KH560 into deionized water and stir to form a hydrophilic fin...

Embodiment 2

[0037] (1) PVDF, hydrophilic SiO2 are dissolved in DMF and acetone and heated and stirred for 3h, then without heating and stirred for 19h, after fully stirring, the concentration of PVDF in the solution is 10wt%, hydrophilic SiO2, the quality: the quality of PVDF= 1:100, the quality of DMF, the quality of acetone = 1:1;

[0038] (2) Electrospinning is carried out with the solution obtained in step (1), and the electrospinning process parameters are adjusted. The first layer uses 20KV voltage, 0.8ml / h advancing rate, 14cm receiving distance, 400r / min, and the spinning time is 2h. The second layer uses 15KV voltage, 2ml / h propulsion rate, 9cm receiving distance, 300r / min, spinning time is 2h, the third layer uses 20KV voltage, 0.8ml / h propulsion rate, 14cm receiving distance, 400r / min, spinning The silk time is 2h, thus forming a three-layer composite PVDF nano-membrane;

[0039] (3) Add PVP and KH560 into deionized water and stir to form a hydrophilic finishing agent; wherein...

Embodiment 3

[0043] (1) PVDF, hydrophilic SiO2 are dissolved in DMF and acetone and heated and stirred for 4h, then without heating and stirred for 18h, after fully stirring, the concentration of PVDF in the solution is 10wt%, hydrophilic SiO2, the quality: the quality of PVDF= 1:100, the quality of DMF, the quality of acetone = 1:1;

[0044] (2) Electrospinning is carried out with the solution obtained in step (1), and the electrospinning process parameters are adjusted. The first layer uses 20KV voltage, 0.8ml / h advancing rate, 14cm receiving distance, 400r / min, and the spinning time is 2h. The second layer uses 15KV voltage, 2ml / h propulsion rate, 9cm receiving distance, 300r / min, spinning time is 2h, the third layer uses 20KV voltage, 0.8ml / h propulsion rate, 14cm receiving distance, 400r / min, spinning The silk time is 2h, thus forming a three-layer composite PVDF nano-membrane;

[0045] (3) Add PVP and KH560 into deionized water and stir to form a hydrophilic finishing agent; wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com