Bacterial strain for producing acid protease through liquid fermentation and application of bacterial strain

An acid protease and liquid fermentation technology, which is applied in the field of Aspergillus niger strain and its liquid fermentation production of acid protease, and can solve the problems of limiting the wide application of acid protease, high overall cost, limited production output and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

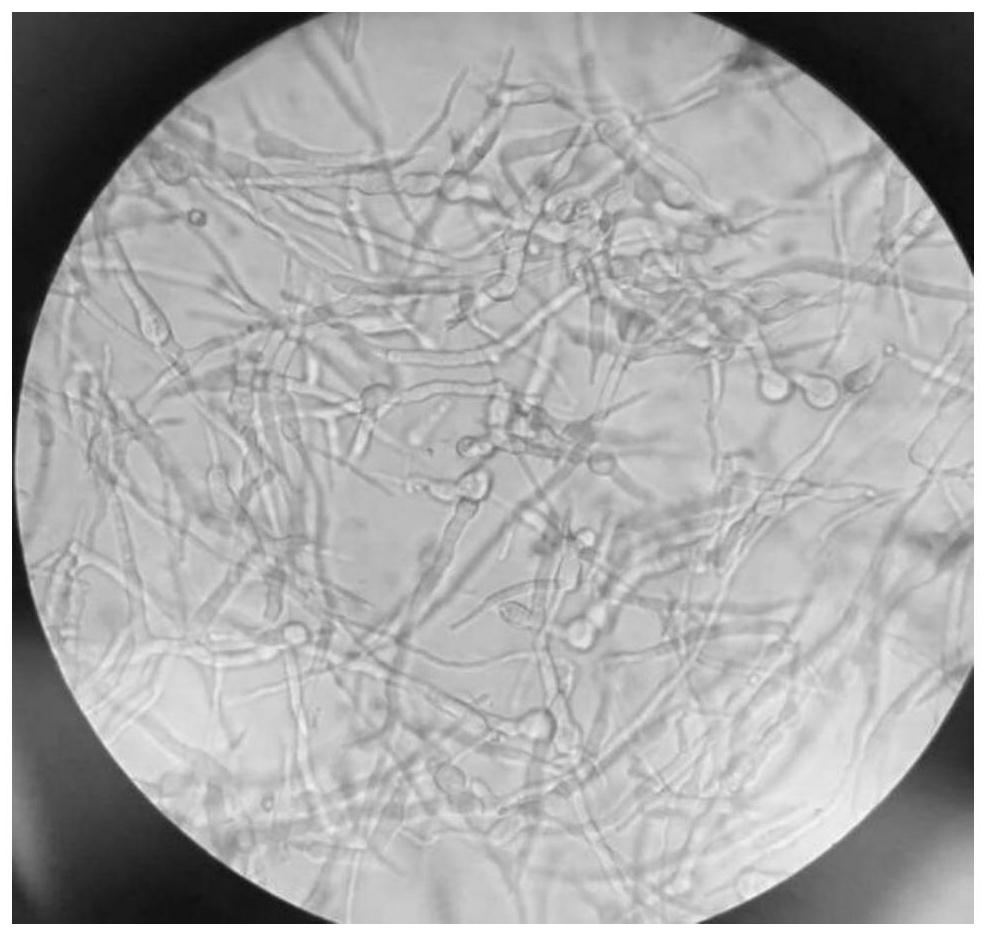

[0062] The acquisition and mutagenesis of embodiment 1 Aspergillus niger ESP1023

[0063] A Aspergillus niger strain isolated from the soil around the fermented bean curd factory in Yichang City, Hubei Province was mutated and domesticated by combining ultraviolet mutagenesis technology and ARTP mutagenesis technology to obtain the new acid-producing protease ability provided by the present invention. Excellent bacterial strains, the specific method is as follows.

[0064] 1. The Aspergillus niger strain isolated from soil is subjected to ultraviolet mutagenesis:

[0065] Bacterial suspension preparation: Wash out the spores of eggplant bottles cultivated to the logarithmic phase with 50mL of normal saline; shake evenly; take 15ml of spore suspension and pour it into a sterile plate;

[0066] In an environment without visible light, place the plate containing the spore liquid vertically under a UV lamp with a distance of 28 cm, an irradiation time of 270 s, and a power of 40 ...

Embodiment 2

[0088] Embodiment 2 Aspergillus niger ESP1023 bacterial strain liquid fermentation produces acid protease

[0089] Strain activation: inoculate the glycerol tube seeds of the Aspergillus niger ESP1023 strain into fresh PDA eggplant bottle medium, and culture at 29°C for 6 days.

[0090] Seed shake flask fermentation: Pick a large ring of mature seed lawn from the eggplant bottle and put it into freshly prepared seed shake flask culture medium. Under the condition of 29°C, 180rpm shake flask culture for 30h, the weight volume ratio of seed shake flask medium (g / ml), the components are as follows: glucose 1.5%, corn steep liquor 2.0%, ammonium sulfate 0.5%, magnesium sulfate 0.1%, potassium dihydrogen phosphate 1.5%, calcium chloride 0.05%, trace element A mother liquor 0.04%; The pH is controlled at 5.5, sterilized at 115°C for 30 minutes, and the trace element A mother solution is made of the following components: in terms of mass volume ratio (g / ml), 0.6% iron citrate, 0.08% ...

Embodiment 3

[0096] Embodiment 3 Aspergillus niger ESP1023 bacterial strain liquid fermentation produces acid protease

[0097] Strain activation: inoculate the glycerol tube seeds of the Aspergillus niger ESP1023 strain into fresh PDA eggplant bottle medium, and culture at 29° C. for 5 days.

[0098] Seed shake flask fermentation: Pick a large ring of mature seed lawn from the eggplant bottle and put it into freshly prepared seed shake flask culture medium. Under the condition of 29°C, 180rpm shake flask culture for 30h, the weight volume ratio of seed shake flask medium (g / ml), the components are as follows: glucose 2.0%, corn steep liquor 2.0%, ammonium sulfate 0.8%, magnesium sulfate 0.1%, potassium dihydrogen phosphate 0.95%, calcium chloride 0.05%, trace element A mother liquor 0.04%; The pH is controlled at 5.0, sterilized at 115°C for 30 minutes, and the trace element A mother solution is made of the following components: in terms of mass volume ratio (g / ml), 0.6% iron citrate, 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com