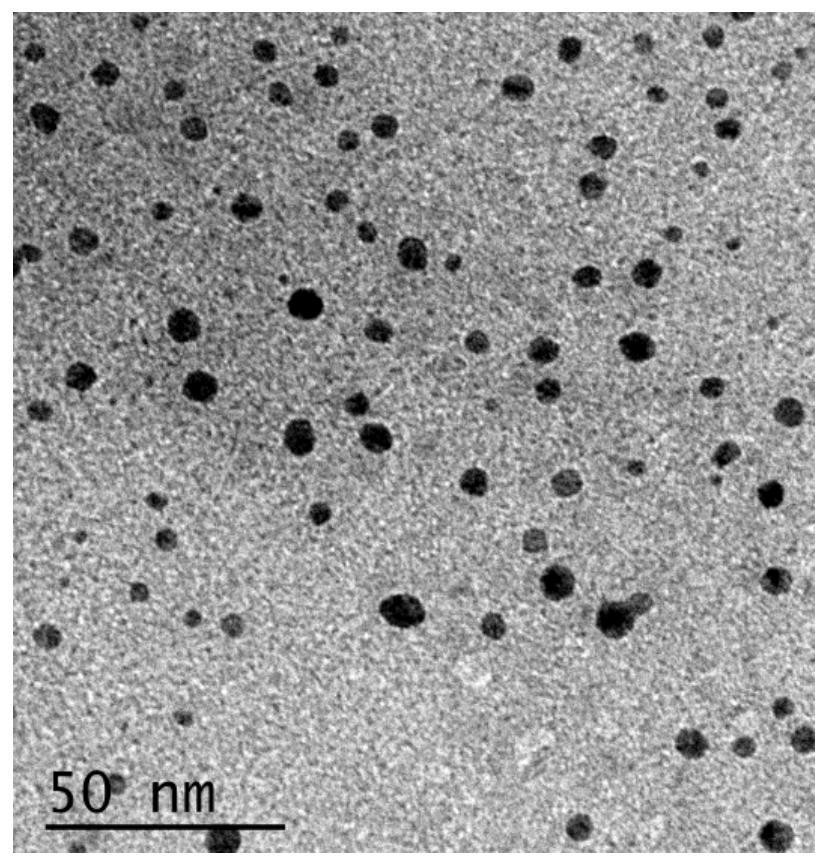

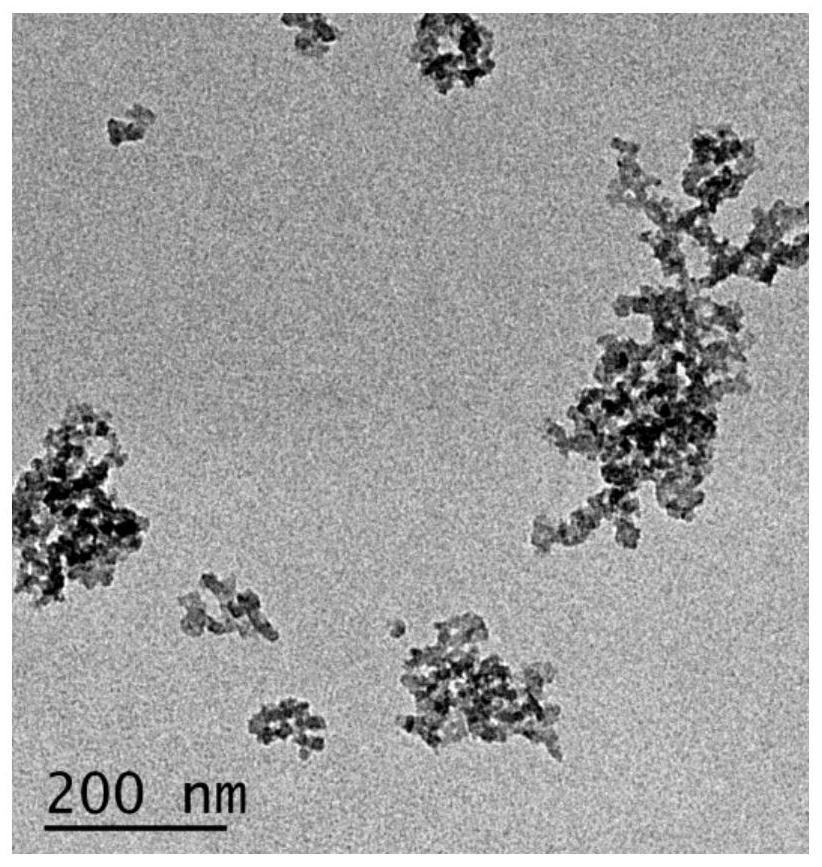

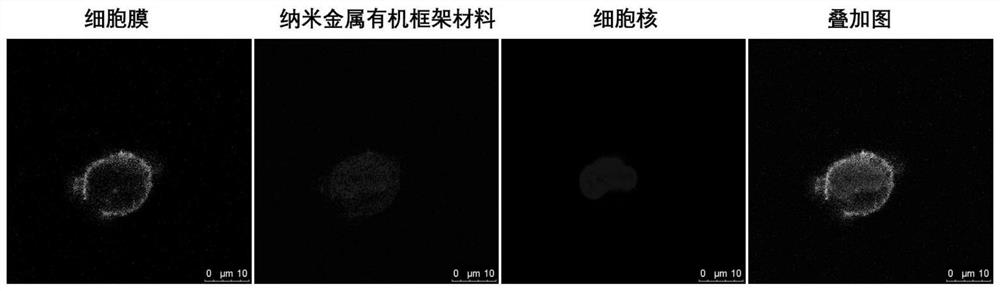

Ultra-small nano metal organic framework material and preparation method thereof

A metal-organic framework and organic framework technology, which is applied in the field of ultra-small nano-metal organic framework materials and their preparation, can solve the problems of increasing production costs, low activity, and limiting industrial applications, and reduce the generation and preparation of by-products The effect of simple process and short solvothermal reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of ultra-small nanometer metal organic framework material, as follows:

[0035] 1) Weigh 1mol FeCl 3 2THF and 3mol CuCl 2 ·2THF, 10mol organic ligands, wherein the organic ligands are mixed with terephthalic acid, mes-tetrakis(4-carboxyphenyl)porphine and trimesic acid in a molar ratio of 3:2:8. After mixing the weighed raw materials, add a solvent mixed with ethanol and o-dichlorobenzene at a volume ratio of 2:1 to prepare a mixed solution with a metal concentration of 0.1mol / L;

[0036] 2) Add a surfactant that accounts for 2% of the metal source mass in the mixed solution, and mix well to obtain a mother liquor, wherein the surfactant is sodium dodecylbenzenesulfonate and Tween 80 in a mass ratio of 1:1 mixed;

[0037] 3) Put the mother liquor in a reaction kettle, and carry out solvothermal reaction under the protection of a reducing atmosphere. The reaction temperature is 100°C, and the reaction time is 1h. The reducing atmosphere is a mixtu...

Embodiment 2

[0040] A preparation method of ultra-small nanometer metal organic framework material, as follows:

[0041] 1) Weigh 1mol FeCl 3 2THF and 1mol CuCl 2 2THF, 1molZnCl 2 · 2THF, 15mol organic ligand, wherein the organic ligand is a mixture of terephthalic acid, meso-tetrakis(4-carboxyphenyl) porphine and trimesic acid in a molar ratio of 3:5:8. After mixing the weighed raw materials, add a solvent mixed with ethanol and o-dichlorobenzene at a volume ratio of 3:1 to prepare a mixed solution with a metal concentration of 0.1mol / L;

[0042] 2) Add a surfactant that accounts for 2% of the metal source mass in the mixed solution, and mix well to obtain a mother liquor, wherein the surfactant is sodium dodecylbenzenesulfonate and Tween 80 in a mass ratio of 1:1 mixed;

[0043] 3) Put the mother liquor in a reaction kettle, and carry out solvothermal reaction under the protection of a reducing atmosphere. The reaction temperature is 100°C, and the reaction time is 1h. The reducing a...

Embodiment 3

[0046] A preparation method of ultra-small nanometer metal organic framework material, as follows:

[0047] 1) Weigh 1mol FeCl 3 2THF and 1mol ZnCl 2 · 2THF, 4mol organic ligand, wherein the organic ligand is a mixture of terephthalic acid, medium-tetrakis(4-carboxyphenyl) porphine and trimesic acid in a molar ratio of 3:1:8. After mixing the weighed raw materials, add a solvent mixed with ethanol and o-dichlorobenzene at a volume ratio of 1:1 to prepare a mixed solution with a metal concentration of 0.1mol / L;

[0048] 2) Add a surfactant accounting for 3% of the metal source mass in the mixed solution, and mix well to obtain a mother liquor, wherein the surfactant is sodium dodecylbenzenesulfonate and Tween 60 in a mass ratio of 1:1 mixed;

[0049]3) Put the mother liquor in a reaction kettle, and carry out solvothermal reaction under the protection of a reducing atmosphere. The reaction temperature is 100°C, and the reaction time is 1h. The reducing atmosphere is a mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com