Structure and preparation technology of a kind of mixed explosive

A technology of mixed explosives and explosives, which is applied in the direction of explosives, non-explosive/non-heating agent components, non-explosive fillers/gelling agents/thickeners, etc., which can solve the problem that mixed explosives are difficult to balance power and safety, and achieve reduction Effects of particle sensitivity, complete spreading, and strong detonation output ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

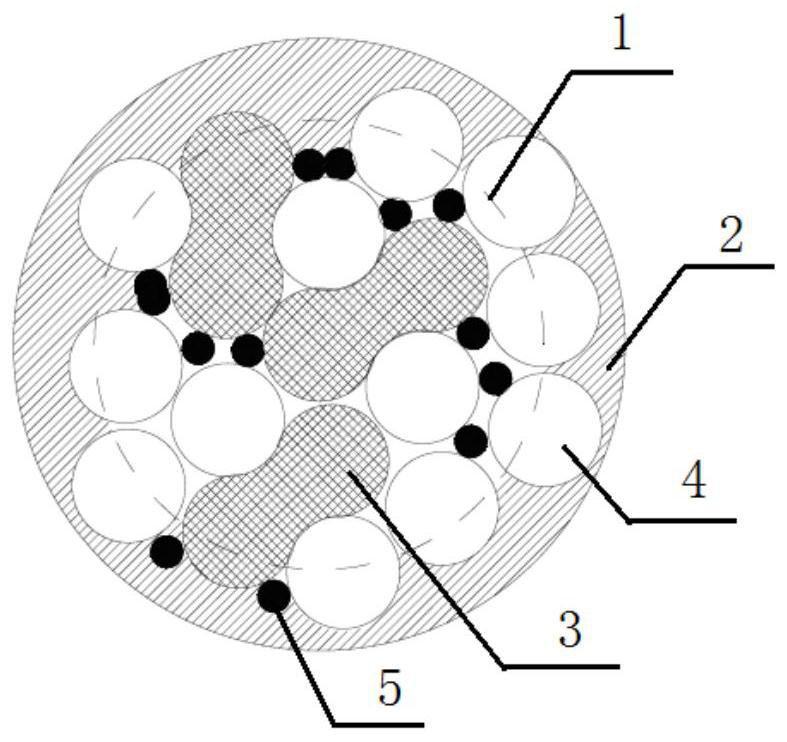

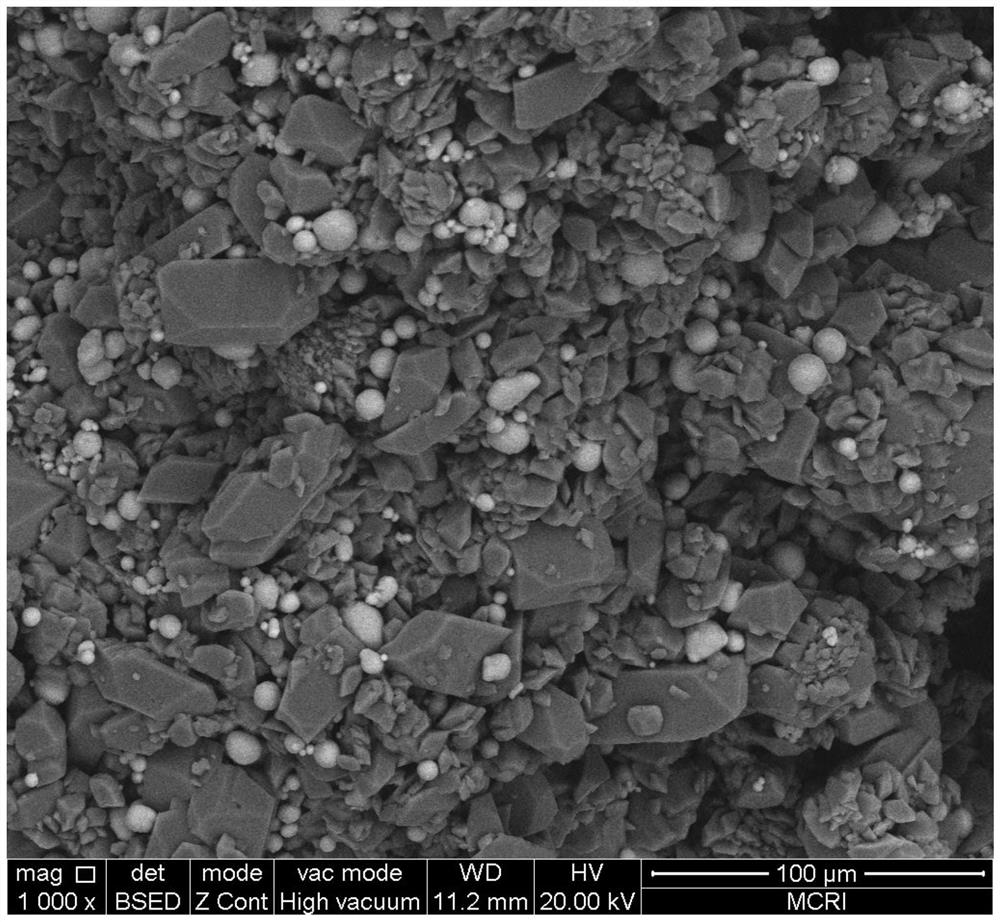

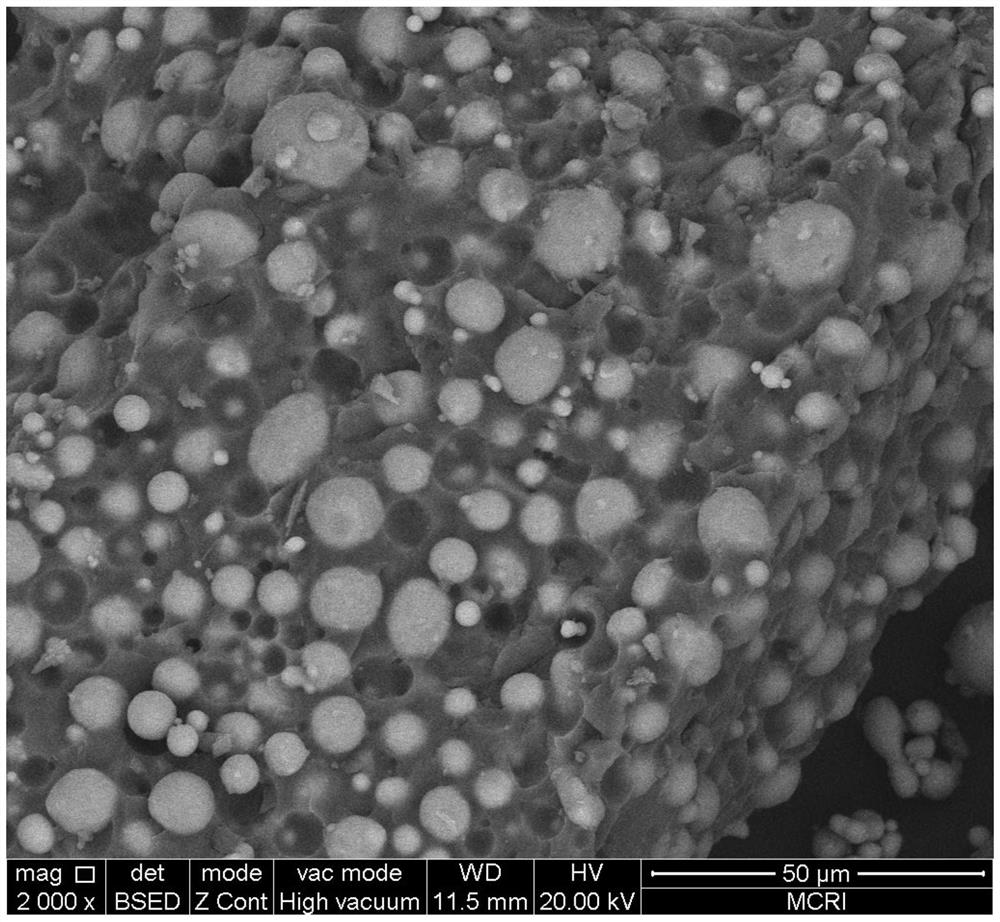

[0061] This embodiment provides a mixed explosive structure including mixed crystal particles 1, such as figure 1 As shown, the mixed crystal particle 1 is coated with a coating film 2;

[0062] The mixed crystal particles 1 include CL-20 explosive 3 and aluminum powder 4, and the CL-20 explosive 3 and aluminum powder 4 are partially bonded by a binder 5;

[0063] The coating film 2 is composed of paraffin wax, talcum powder and sodium dodecylbenzenesulfonate.

[0064] CL-20 explosives are ε-crystalline spherical particles with a maximum particle size of 800 nanometers.

[0065] The aluminum powder is a spherical particle with a maximum diameter of 600 nanometers.

[0066] The binder is EVA.

[0067] The mixed explosive structure is composed of the following raw materials in parts by weight: 95% of CL-20 explosive and aluminum powder, 1% of binder, 3.8% of paraffin, talcum powder and sodium dodecylbenzenesulfonate 0.2%.

[0068] The weight ratio of CL-20 explosive and alu...

Embodiment 2

[0084] This embodiment provides a mixed explosive structure, which is basically the same as the mixed explosive structure in Example 1, the only difference being that in this embodiment:

[0085] The mixed explosive structure consists of the following raw materials in parts by weight: 95% of CL-20 explosive and aluminum powder, 2% of binder, 2.8% of paraffin, talcum powder and sodium dodecylbenzenesulfonate 0.2%.

[0086] CL-20 explosives are ε-crystalline spherical particles with a maximum particle size of 700 nanometers.

[0087] The aluminum powder is a spherical particle with a maximum diameter of 350 nanometers.

[0088] The binder is EVA.

[0089] The weight ratio of CL-20 explosive and aluminum powder is 85:10.

[0090] The weight ratio of talcum powder and sodium dodecylbenzenesulfonate is 1:1.

[0091] The melting point of paraffin is 58°C.

[0092] The molding process of the mixed explosive structure in this embodiment is the same as that of the mixed explosive ...

Embodiment 3

[0096] This example provides a mixed explosive structure, which is basically the same as the mixed explosive structure in Example 1, the only difference being that in this example: the weight ratio of CL-20 explosive to aluminum powder is 80:15.

[0097] The molding process of the mixed explosive structure in this embodiment is the same as that of the mixed explosive structure in Example 1.

[0098] The characterization results of the mixed explosive structure in this example are basically the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com