Sulfuric acid production wastewater treatment method

A technology for wastewater treatment and sulfuric acid production, which is applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

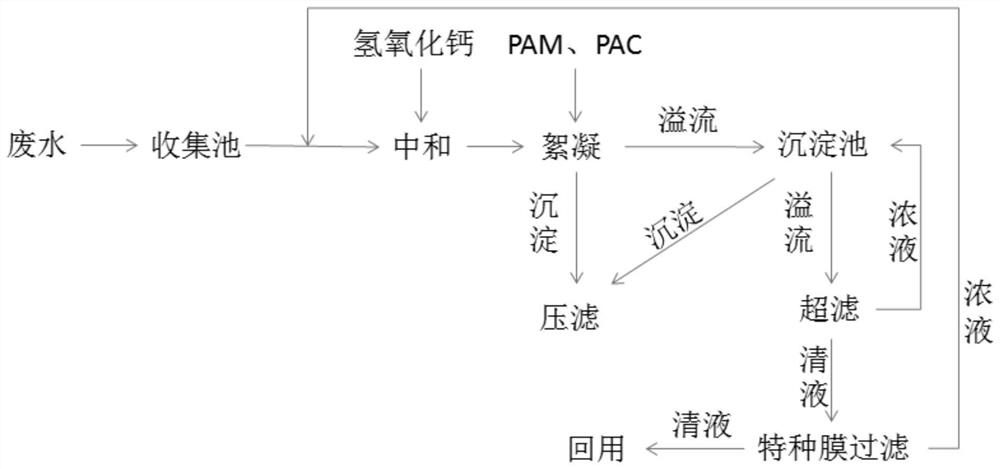

[0033] A kind of sulfuric acid production wastewater treatment method, comprises the following steps:

[0034] (1) the production waste water of sulfuric acid is passed in the collecting pool and collects;

[0035] (2) adding calcium hydroxide and production waste water in the collection pool to neutralize;

[0036] (3) Add PAM flocculants and PAC flocculants to the neutralized production wastewater for flocculation and sedimentation treatment, so that the calcium sulfate particles in the production wastewater form colloids, and overflow into the sedimentation tank for secondary settlement, and other hydroxides form The precipitated sludge is filtered through a plate and frame filter press;

[0037] (4) The sedimentation sludge produced by the secondary settlement is imported into the sedimentation sludge in step 3 for pressure filtration treatment, the overflow produced by the secondary settlement flows into the ultrafiltration machine for ultrafiltration treatment, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com