Reverse shipbuilding jig frame structure

A tire frame and reverse technology, which is applied in the direction of berths, dry docks, ships, etc., can solve problems such as unsafety, reduce work efficiency, increase labor burden of workers, etc., and achieve the effect of adjusting the height of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

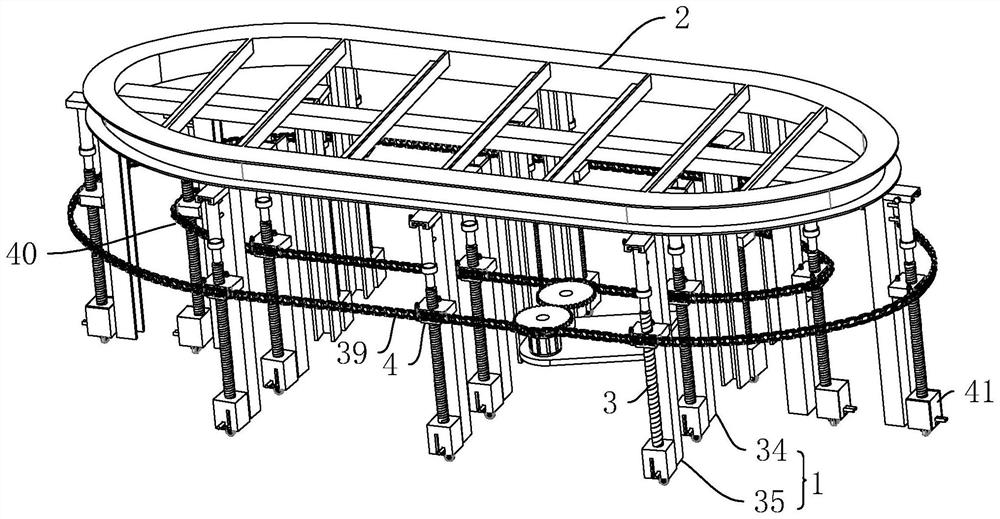

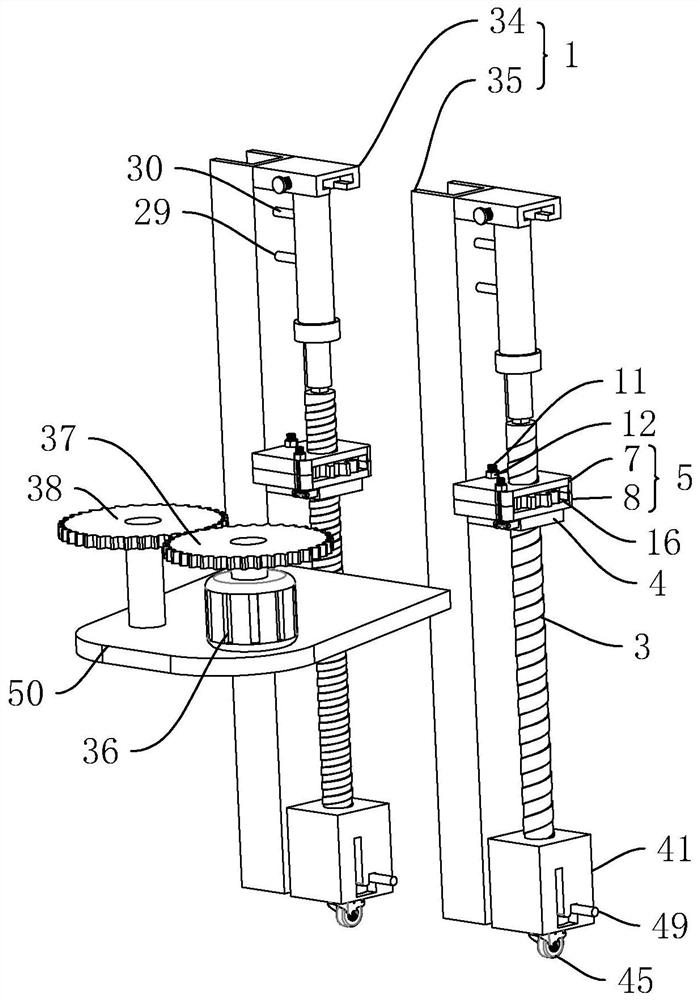

[0036] The following is attached Figure 1-5 The application is described in further detail.

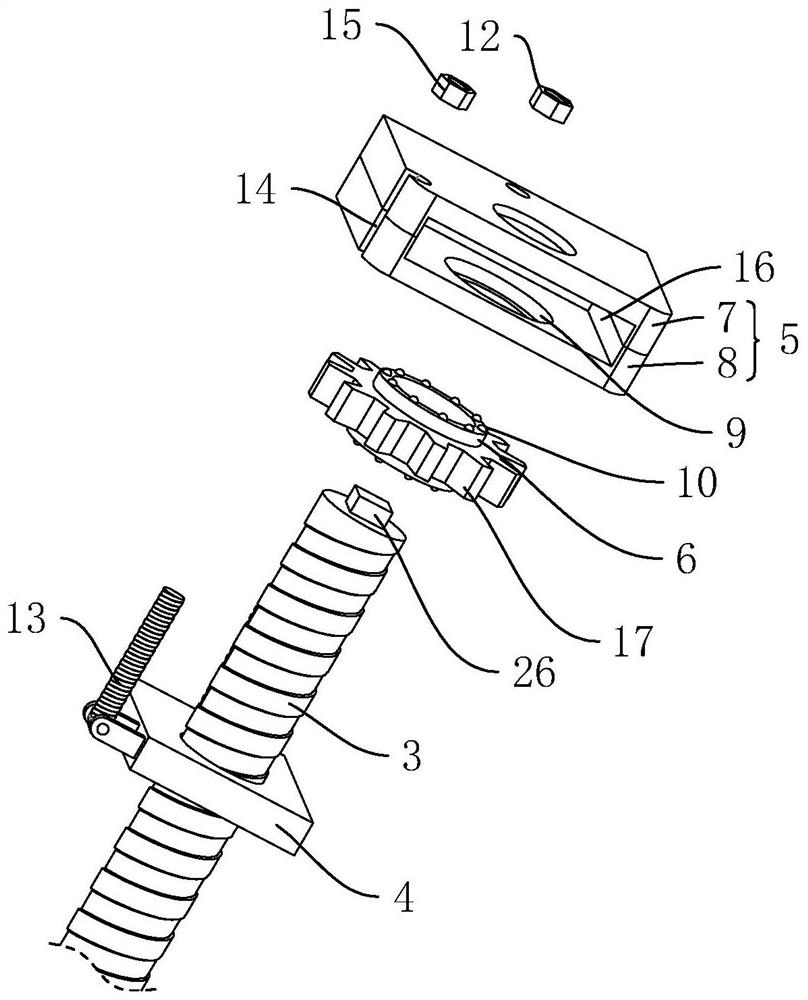

[0037] The embodiment of the present application discloses a reverse shipbuilding tire frame structure. refer to figure 1 and figure 2 , a reverse shipbuilding tire frame structure, including several vertically arranged brackets 1 and a support frame 2 welded on the upper end of the bracket 1, the support frame 2 connects several brackets 1 and is arranged horizontally to support the hull. The support rod 3 corresponding to the support 1 and vertically arranged is connected to the support 1, and the drive device for driving the support rod 3 to move in the vertical direction is arranged on the support 1. The drive device includes welding on the side wall of the support 1 On the support block 4, the upper surface of the support block 4 is horizontally arranged, and a connecting block 5 arranged horizontally is installed on the upper surface of the support block 4, and a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com